Showing 61–72 of 131 resultsSorted by latest

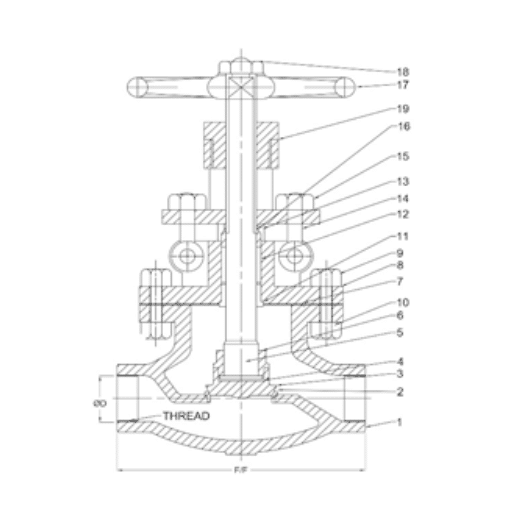

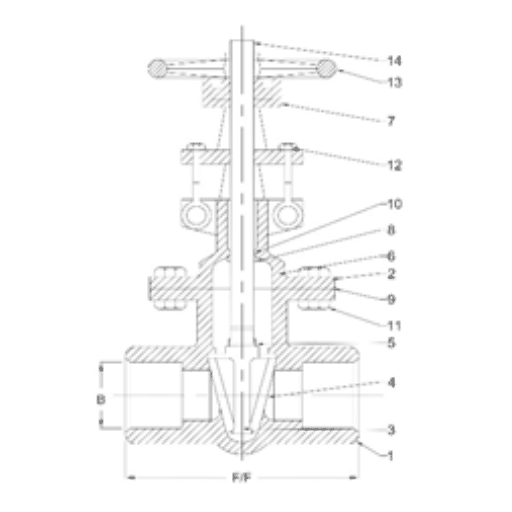

GLOBE VALVE, Screw End (800#)

TECHNICAL DATA

| Design Std. | As per BS 5352 / ASME B 16.34 |

| End Connection | Screw End |

| Testing & Std. | As per API 598 or ISO 5208 |

| Size, 800# | 15 mm to 50 mm (1/2” to 2”) |

Bill Of Material

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Body seat | SS410 (13% CR)/CF8/CF8M |

| 3 | Disc | WCB +13% CR STEEL |

| 4 | Disc washer | 13% CR STEEL |

| 5 | Stem | SS410 / SS304 / SS316 |

| 6 | Disc Stem Nut | 13% CR STEEL |

| 7 | Gasket | SPW SS304 GRAPHITE FILL |

| 8 | Bonnet | WCB/CF8/CF8M |

| 9 | Stud | ASTM A193 Gr. B7 |

| 10 | Stud Nut | ASTM A194 Gr. B2H |

| 11 | Back Seat Bush | SS410/SS304/SS316 |

| 12 | Spacer | 13% CR STEEL |

| 13 | Packing | GRAPHITE |

| 14 | Eye Bolt | MS/SS |

| 15 | Eye Bolt Nut | MS/SS |

| 16 | Gland | SS410/SS304/SS316 |

| 17 | Hand Wheel | MALLEABLE IRON |

| 18 | Hand Wheel Nut | MS |

| 19 | Yoke Sleeve | EN8 |

Dimensions 800#

| Size | F/F | B |

| 15 | 85 | 21.7 |

| 20 | 92 | 27.1 |

| 25 | 106 | 33.8 |

| 30 | 122 | 42.5 |

| 40 | 127 | 48.6 |

All dimensions are in mm.

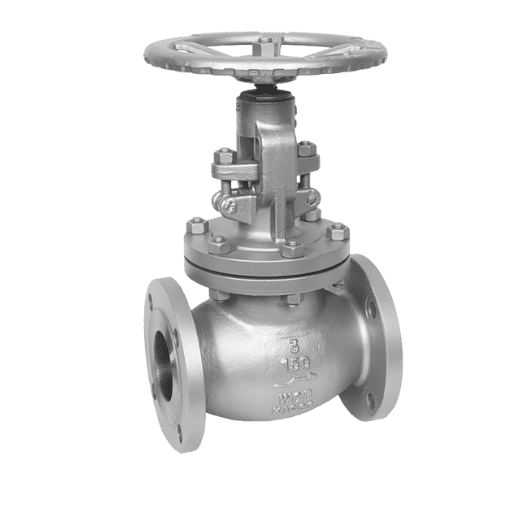

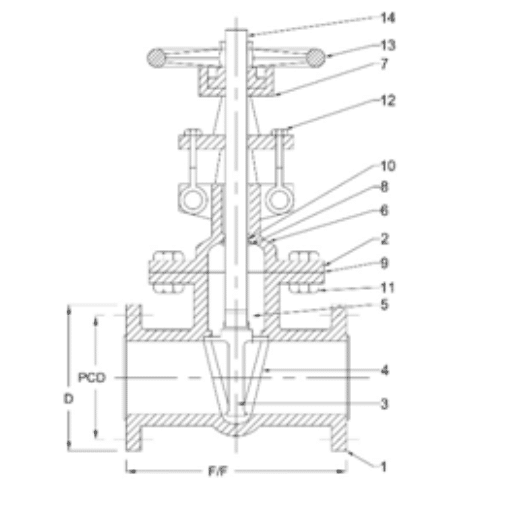

Globe Valve – Flanged End (150#, 300#)

TECHNICAL DATA

| Design Std. | As per BS 1873 / ASME B 16.34 |

| End Connection | Flanged End |

| Testing & Std. | As per API 598 or ISO 5208 |

| Size, 150# | 25 mm to 300 mm (1” to 12”) |

| Size, 300# | 50 mm to 300 mm (2” to 12”) |

Bill Of Material

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Body seat | SS410 (13% CR)/CF8/CF8M |

| 3 | Disc | WCB +13% CR STEEL |

| 4 | Disc washer | 13% CR STEEL |

| 5 | Stem | SS410 / SS304 / SS316 |

| 6 | Disc Stem Nut | 13% CR STEEL |

| 7 | Gasket | SPW SS304 GRAPHITE FILL |

| 8 | Bonnet | WCB/CF8/CF8M |

| 9 | Stud | ASTM A193 Gr. B7 |

| 10 | Stud Nut | ASTM A194 Gr. B2H |

| 11 | Back Seat Bush | SS410/SS304/SS316 |

| 12 | Spacer | 13% CR STEEL |

| 13 | Packing | GRAPHITE |

| 14 | Eye Bolt | MS/SS |

| 15 | Eye Bolt Nut | MS/SS |

| 16 | Gland | SS410/SS304/SS316 |

| 17 | Hand Wheel | MALLEABLE IRON |

| 18 | Hand Wheel Nut | MS |

| 19 | Yoke Sleeve | EN8 |

Dimensions 150#

| Size | Dia D | PCD | F/F |

| 25 | 110 | 79.5 | 127 |

| 40 | 125 | 98.5 | 165 |

| 50 | 150 | 120.5 | 203 |

| 65 | 180 | 139.5 | 216 |

| 80 | 190 | 152.5 | 241 |

| 100 | 230 | 190.5 | 292 |

| 150 | 280 | 241.5 | 406 |

| 200 | 345 | 298.5 | 495 |

| 250 | 405 | 362 | 622 |

| 300 | 485 | 432 | 698 |

Dimensions 300#

| Size | Dia D | PCD | F/F |

| 50 | 165 | 127 | 267 |

| 65 | 190 | 149 | 292 |

| 80 | 210 | 168.5 | 318 |

| 100 | 255 | 200 | 356 |

| 150 | 320 | 270 | 444 |

| 200 | 380 | 330 | 559 |

| 250 | 445 | 387.5 | 622 |

| 300 | 520 | 451 | 711 |

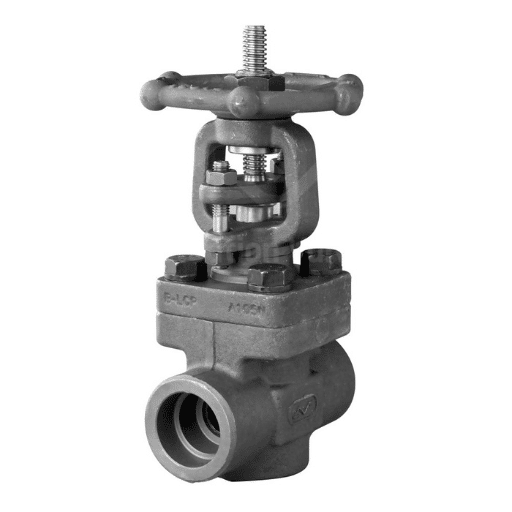

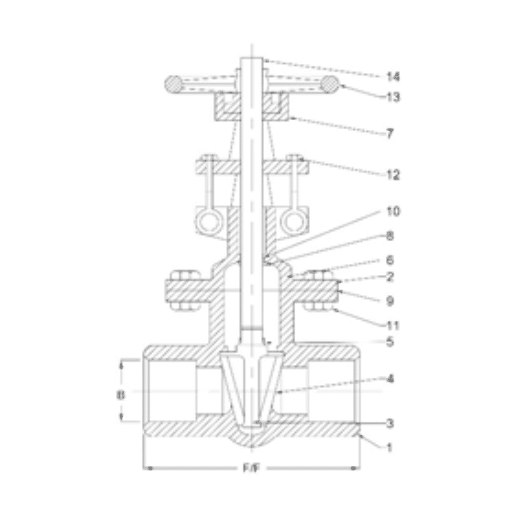

GATE VALVE, Socket weld (800#)

Technical Data

| Design Std. | As per BS 1414 |

| End Connection | Threaded End |

| Testing & Std. | As per API 598 / ISO 5208 |

| Size, 150# & 300# | 15 mm to 80 mm (1/2" to 3") |

Bill Of Material

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Bonnet | WCB / CF8 / CF8M |

| 3 | Wedge | WCB (13% CR) / CF8 / CF8M |

| 4 | Seat Ring | SS410 (13% CR) / CF8 / CF8M |

| 5 | Stem | SS410 / SS304 / SS316 |

| 6 | Gland | SS410 / SS304 / SS316 |

| 7 | Yoke Sleeve | SS410 / SS304 / SS316 |

| 8 | Back Seat Bush | CS/CF8/CF8M |

| 9 | Gasket | EN8 |

| 10 | Gland Packing | MS/SS |

| 11 | Bonet Stud | MALLEABLE IRON |

| 12 | Bolt | MS |

| 13 | Hand wheel | SPW SS304 GRAPHITE FILLED |

| 14 | Hand wheel Nut | GRAPHITE |

Dimensions 800#

| Size | F/F | B |

| 15 | 51 | 62 |

| 20 | 55 | 66 |

| 25 | 63 | 78 |

| 30 | 71 | 85 |

| 40 | 73 | 94 |

| 50 | 83 | 101 |

| 60 | 108 | 127 |

| 80 | 117 | 143 |

All dimensions are in mm.

GATE VALVE, Screw End (150#, 300#)

| Design Std. | As per BS 5352/ ASME B16.34 |

| End Connection | Screw End |

| Testing & Std. | As per API 598 / ISO 5208 |

| Size, 150# | 15 mm to 50 mm (1/2" to 2") |

Bill Of Material

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Bonnet | WCB / CF8 / CF8M |

| 3 | Wedge | WCB (13% CR) / CF8 / CF8M |

| 4 | Seat Ring | SS410 (13% CR) / CF8 / CF8M |

| 5 | Stem | SS410 / SS304 / SS316 |

| 6 | Gland | SS410 / SS304 / SS316 |

| 7 | Yoke Sleeve | SS410 / SS304 / SS316 |

| 8 | Back Seat Bush | CS/CF8/CF8M |

| 9 | Gasket | EN8 |

| 10 | Gland Packing | MS/SS |

| 11 | Bonet Stud | MALLEABLE IRON |

| 12 | Bolt | MS |

| 13 | Hand wheel | SPW SS304 GRAPHITE FILLED |

| 14 | Hand wheel Nut | GRAPHITE |

Dimensions 150#

Technical Data

| Size | F/F | B |

| 15 | 85 | 21.7 |

| 20 | 92 | 27.1 |

| 25 | 106 | 33.8 |

| 30 | 122 | 42.6 |

| 40 | 127 | 48.5 |

| 50 | 140 | 50.8 |

All dimensions are in mm.

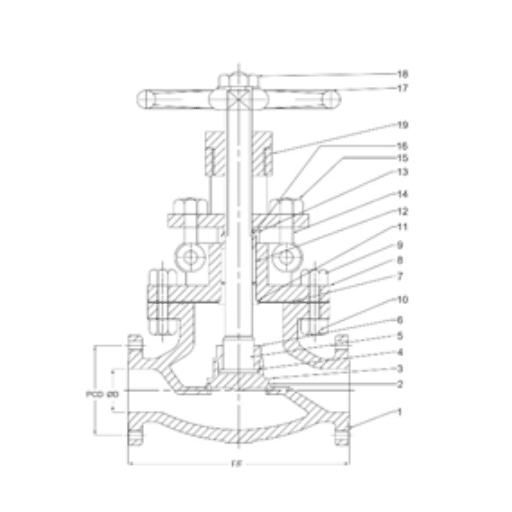

GATE VALVE, Flanged End (150# , 300#)

Technical Data

| Design Std. | As per BS 1414 |

| End Connection | Flanged End |

| Testing & Std. | As per API 598 / ISO 5208 |

| Size, 150# & 300# | 15 mm to 300 mm (1/2" to 12") |

Bill Of Material

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Bonnet | WCB / CF8 / CF8M |

| 3 | Wedge | WCB (13% CR) / CF8 / CF8M |

| 4 | Seat Ring | SS410 (13% CR) / CF8 / CF8M |

| 5 | Stem | SS410 / SS304 / SS316 |

| 6 | Gland | SS410 / SS304 / SS316 |

| 7 | Yoke Sleeve | SS410 / SS304 / SS316 |

| 8 | Back Seat Bush | CS/CF8/CF8M |

| 9 | Gasket | EN8 |

| 10 | Gland Packing | MS/SS |

| 11 | Bonet Stud | MALLEABLE IRON |

| 12 | Bolt | MS |

| 13 | Hand wheel | SPW SS304 GRAPHITE FILLED |

| 14 | Hand wheel Nut | GRAPHITE |

Dimensions 150#

| Size | Dia D | PCD | F/F |

| 15 | 90 | 60.5 | 108 |

| 20 | 100 | 70 | 117 |

| 25 | 110 | 79.5 | 127 |

| 40 | 125 | 98.5 | 165 |

| 50 | 150 | 120.5 | 178 |

| 65 | 180 | 139.5 | 191 |

| 80 | 190 | 152.5 | 203 |

| 100 | 230 | 190.5 | 229 |

| 150 | 280 | 241.5 | 267 |

| 200 | 345 | 298.5 | 292 |

| 250 | 405 | 362 | 330 |

| 300 | 485 | 432 | 356 |

Dimensions 300#

| Size | Dia D | PCD | F/F |

| 15 | 95 | 66.5 | 140 |

| 20 | 115 | 82.5 | 152 |

| 25 | 125 | 89 | 165 |

| 40 | 155 | 114.5 | 190 |

| 50 | 165 | 127 | 216 |

| 65 | 190 | 149 | 241 |

| 80 | 210 | 168.5 | 283 |

| 100 | 255 | 200 | 305 |

| 150 | 320 | 270 | 403 |

| 200 | 380 | 330 | 419 |

| 250 | 445 | 387.5 | 457 |

| 300 | 520 | 451 | 502 |

All dimensions are in mm.

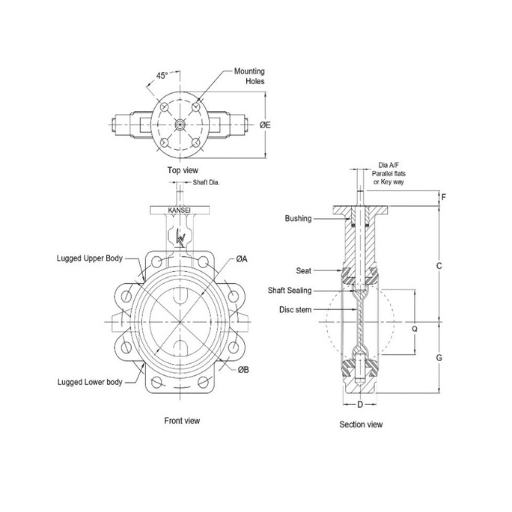

BUTTERFLY VALVE EPDM & EPDM + PTFE seated Centric design

Applications :

Food and beverages, slurries, pneumatic conveying, dry bulk conveying, chemicals, paper stock, mineral processing. This type of valve is highly suitable where bubble-tight shut off with maximum flow area is required.

Suitable for on-off and control services

TECHNICAL DATA

Size: 2” (50 mm) to 20” (500 mm)

Type: Wafer & Lug Design: Centric Bi-directional Pressure: PN10, PN16 Seat: EPDM, PTFE + EPDM Flange Suit To: ANSI 150#, PN10, PN16, BS TableDesign, Manufacturing and Testing Standards – Technology at a Glance

Kansei EPDM and PTFE Centric Bi-directional Butterfly valves are designed to ensure a bubble tight shut off in both direction and provide a Maximum flow area. “A major advantage of Kansei product is an International compatibility.”

The Exclusive Design of two-piece body with one-piece wafer-thin disc stem provide the very less obstruction to flow. Body locating holes provide easy placing and perfect centering of the valve between the flanges. Rounded & Buffed disc edge gives full concentric sealing with lower torque, which gives longer seat life. Kansei designed Primary stem sealing accomplished by a preinstalled contact between seat surface and rounded disc hub area which overtake the pressure rating of valve and prevents the leakage through the stem area to atmosphere. An inbuild ‘O’ ring on the seat surface provide flange sealing and eliminates the need for additional flange gasket. The seat is completely field replaceable and isolated from line media which allows superior performance of valve with extended service life. The seat design in such a way to ensure seal drop-tight and bi-directional at low to high pressure range. Split body for easy maintenance. This product is not recommended for dead end services. This type of valve can be installed in vertical or horizontal pipeline and any intermediate orientation.- Design standard as per EN 593/BS 5155 as standard, another applicable standard on request.

- Testing standard as per API 598 or EN 12266-1 as standard.

- Certificate EN10204 Type 3.1 as standard & Manufacturing under Quality system ISO 9001: 2015.

- Casting inspection as per MSS-SP-55 as standard. Another applicable standard on request.

- Trims available with combination of various Casting material like CI/ DI/ WCB/ CF8/ CF8M/ CF3M/ GR. 4A-5A/ etc. and Seat Material like EPDM / EPDM+PTFE etc.

- 100% factory tested (Hydro, Pneumatic) and Inspected valves as per standard.

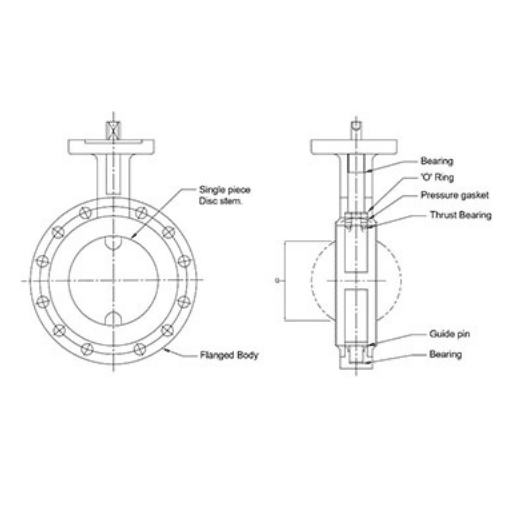

BUTTERFLY VALVE PFA/PTFE Lined, Centric Bi-directional

Applications :

This type of valves are used for multitude and corrosive application, Hazardous and pure liquid, gas, & vapors, free flowing. e.g.: Pharma, foundries and mining, chemicals and petrochemicals, pulp and paper industries, under vessels, & specially used where constant torque and no maintenance is required . Suitable for on-off and control servicesTECHNICAL DATA

Type: Wafer type, Lug type, Flange typeWafer type & Lug type Size: 2” (50 mm) to 12” (300 mm)

Flange type Size: 14” (350 mm) to 16” (400 mm) Design: Centric Bi-directional Pressure: PN10, PN16 Seat: PTFE, PFA, PFA CONDUCTIVE, TFM, TFM CONDUCTIVE Flange Suit To: ANSI 150#Design, Manufacturing and Testing Standards – Technology at a Glance

Kansei PFA/PTFE Lined Centric Bi-directional Butterfly valves are designed to ensure a tight fit around the disc for bubble tight shut off in both direction and provide a constant torque with no maintenance. “A major advantage of Kansei product is an International compatibility.”

The Exceptional Design of one-piece thin disc stem lined with 3mm molded PFA providing high Kv value. The liner and disc are the only two valve parts in contact with the medium. Kansei improved design of disc leading to less deflection at higher pressure and tighter in line seal and for stem sealing system. Primary shaft sealing by preloaded contact between disc and liner hub and the secondary shaft seal by oversizing the shaft diameter in relation to the shaft hole in the liner. The liner and disc are molded and machined to close tolerances to provide low torque, less stress and deformation using opening and closing. PTFE atmospheric seat protects internal components from atmospheric corrosion and provides locating ring for actuator mounting. Fully encapsulated bottom shaft eliminates potential leak path at bottom of valve and eliminates the necessity for further sealing elements- Design standard as per EN 593 or API 609 as standard, another applicable standard on request.

- Testing standard as per API 598 or BS EN 12266-I as standard. 100% bubble tight shut off valve.

- Certificate EN10204 Type 3.1 as standard & Manufacturing under Quality system ISO 9001: 2015.

- Casting inspection as per MSS-SP-55 as standard. Another applicable standard on request.

- Trims available with combination of various Casting material like CI/ DI/ WCB/ CF8M/ CF3M/ GR. 4A-5A/ etc. and Seat Material PTFE.

- 100% factory tested (Hydro, Pneumatic) and Inspected valves as per standard.

- Lever / Gear / Pneumatic / Electric Operation as per customer requirement.

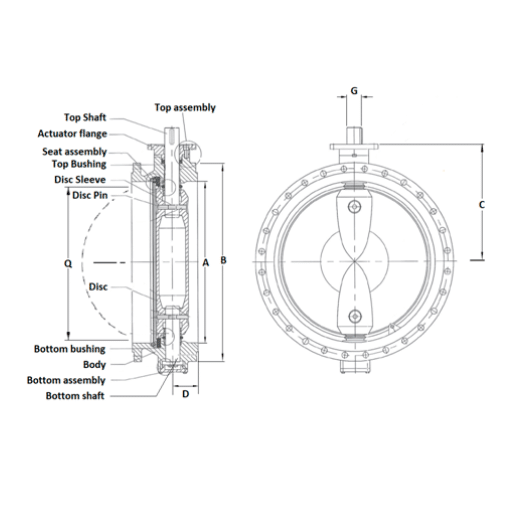

BUTTERFLY VALVE High Performance Double Offset

Applications :

Pharma, Military, Sour gas, Food Processing, Vacuum and Oxygen services, Steam services, Dead-end services, Fire, Chemical industry e.g. Chlorine-Ammonia etc., Reverse Osmosis, Slurry services, Modulating or Special fluids where Flow control is Important.TECHNICAL DATA

Size: 2” (50 mm) to 36” (900 mm)

Type: Wafer, Lug, Flange Design: Eccentric-Double offset Pressure: ANSI Class 150-300 Seat: RTFE, PTFE, UHMWPE, Metal, Fire Safe Flange Suit To: ANSI 150#,300#Design, Manufacturing and Testing Standards – Technology at a Glance

Kansei Wafer, Lug and Flanged Double offset butterfly valves are designed to ensure minimum seat wear, zero leakage shutoff throughout the full pressure range and Uni-Bidirectional to provide a long service life with minimum maintenance. “A major advantage of Kansei product is an International compatibility.”

The Superior two-piece stem design and double offset disc/stem design allows high cycling and eliminates seat deformation when the disc is in the open position. At the initial point of disc opening, the offset disc produces a cam action and pulling the disc from the seat. During opening, disc does not contact the seat which ensures the maximum seat service life with reduced operating torques. The first offset is by locating the stems downstream of the center line of the seat which allows 360-degree unobstructed sealing surface. The second offset is by locating the stems off-center of the vertical axis of the seat. As the valve closes, the camming action converts the rotary motion of the disc to a linear motion which effectively push the disc on seat. Mounting pads integrally casted which provides direct mounting of Gear box and Actuators on valves. Torque requirements of the Kansei High performance double offset valve is significantly lower. The seat is completely isolated from all contact with the line media which allows superior performance of valve with extended service life. Serrations of the seat retainer ring and body secure the seat assembly in place irrespective of disc position. Line media seals to Zero-leakage in both directions and seat is self-adjusting to absorb wear and temperature changes. Replacement of seat is also easy without disturbing the disc or stem. The seat design in such a way to ensure seal drop-tight and bi-directional at low to high pressure range. Seat incorporates a Stainless-Steel wire winding with U-shape envelope to provide better seat life. The wire allows flexibility in both direction of flow. Fire safe: Kansei High performance double offset valves having firesafe seat design options in wafer, lug and flange valves. Fire safe design combines superior performance, extended service life. In normal service, the fire safe design with Soft seat and Metal seat to ensure zero-leakage in both directions of line media flow in full rated pressure and temperature range. In the fire condition, soft seat will be destroyed either partially or fully by excessive heat and metal seat will take place to provide constant sealing. Fire safe packing arrangement with three rings of graphite to create a superior and high temperature sealing.- Design standard as per EN 593 or API 609 (cat. B) as standard, another applicable standard on request.

- Testing standard as per API 598 and FCI 70-2.

- Certificate EN10204 Type 3.1 as standard & Manufacturing under Quality system ISO 9001: 2015.

- Casting inspection as per MSS-SP-55 as standard. Another applicable standard on request.

- Trims available with combination of various Casting material like WCB/ CF8/ CF8M/ CF3M/ GR. 4A-5A/ NAB/ Aluminum Alloys etc. and Seat Material like RTEF/ PTFE/ UHMWPE/ METAL/ FIRE SAFE.

- 100% factory tested (Hydro, Pneumatic) and Inspected valves as per standard.

BUTTERFLY VALVE Large Size Double Flanged, Eccentric Design

Applications:

Power plants, Water works, Municipal water treatment, Cooling systems, Industrial applications etc.TECHNICAL DATA

Suitable for on-off and control services Size: 20” (500 mm) to 80” (2000 mm) Type: Double Flanged Design: Eccentric Pressure: PN6, PN10, PN16, PN20, PN25 Seat: EPDM, BUNA-N, VITON Flange Suit To: PN6, PN10, PN16, PN20, PN25,ANSI, JIS ANSI, BS, DIN, ISO, ISDesign, Manufacturing and Testing Standards – Technology at a Glance

Kansei Double flanged Eccentric Large Butterfly valves are designed to accommodate Flange drilling JIS, ANSI, DIN, BS. Also providing dead-end service capability with downstream piping removed. Each size valve flange has been designed to have the maximum outside diameter and maximum thickness of the nominated flange standards. K35 type valves provides the robust features to ensure reliable performance and long service life. “A major advantage of Kansei product is an International compatibility.”

The valve face to face in accordance with EN 558, BS 5155 Short, ISO 5752 Table 4, EN-593 and AWWA C-504, AWWA C-207. Mounting cast flange designed in accordance to ISO 5211. The Replaceable Seat design meets the requirements of seat replaceability on field without special tooling, dismantling and removing the valve from line. Also provide better shut-off and longer service life. The seat is of a molded construction and fits easily into the body which also reduce seating torque with disc edge contours. The Seat is adjustable to optimize the required shut-off tightness to comply the torque both for unidirectional and directional operation. The Eccentric design provides energy efficient flow control. Stainless steel disc edge protects against corrosion and eliminates the possibility of restricted sealing. Upper and Lower shaft bearings prevent shaft deflection and provide optimum guidance to increase the valve life. High strength and Full diameter Shafts remain dry and provides positive disc control with a minimum flow restriction. Sleeve bearings are self-lubricated which allows valve installation with the shaft vertical or horizontal. Thrust bearings are provided with the adjustment to ensure good axial positioning of the disc due to forces applied by seat and shaft seals to the disc. The secondary seal is provided to seal the bearing area from environment, and it will also act as a primary seal in account of failure of primary seal, Rubber lining is additional option for this product.- Design standard as per EN 593, AWWA C-504, AWWA C-207 as standard, another applicable standard on request.

- Testing standard as per API 598 or BS EN 12266-I as standard. 100% bubble tight shut off valve.

- Certificate EN10204 Type 3.1 as standard & Manufacturing under Quality system ISO 9001: 2015.

- Casting inspection as per MSS-SP-55 as standard. Another applicable standard on request.

- Trims available with combination of various Casting material like CI / DI / NICI / NIDI / WCB / CF8 / CF8M / CF3M/ GR. 4A-5A / NAB etc. and Seat Material like EPDM / BUNA-N / VITON etc. Coating and Lining as per Customer requirement.

- 100% factory tested (Hydro, Pneumatic) and Inspected valves as per standard.

- Gear / Pneumatic / Electric / Hydraulic Operation as per customer requirement.

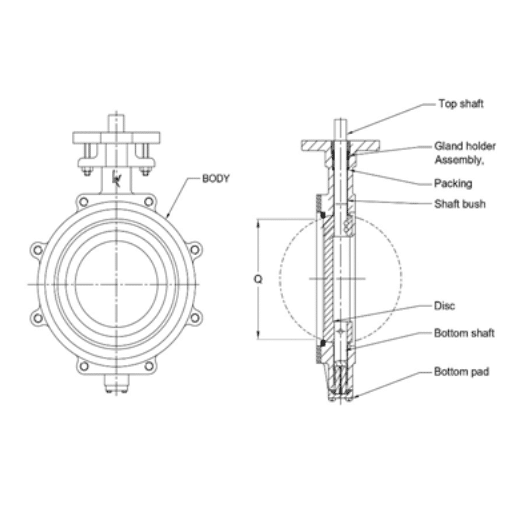

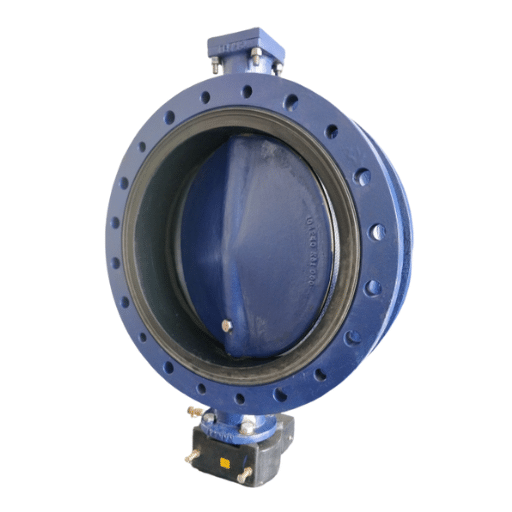

BUTTERFLY VALVE Centric, Bi-Directional, Wafer, Lug & Double Flanged Type

Applications :

Ship building, Chemical industry, Power plants, Tank drains, Water works, Sugar mill, Infra, Dead-end, Liquid, Gases, Bulk handling, Fire protection, Cooling systems, Food and Beverages etc.TECHNICAL DATA:

Type : Wafer type, Lug type, Flanged End Wafer type Size: 2” (50 mm) to 36” (900 mm) Lug type Size: 2” (50 mm) to 32” (800 mm) Flanged End: Size: 2” (50 mm) to 24” (600 mm) Design: Centric-Bi directional Pressure: PN6, PN10, PN16 Pressure Class: 150# Seat: EPDM, EPDM-FOOD GRADE, BONDED/LINING, BUNA-N, VITONDesign, Manufacturing and Testing Standards – Technology at a Glance

Kansei Wafer and Lug Centric Bi-directional butterfly valves are designed with few moving parts to provide a long service life with minimum maintenance. “A major advantage of Kansei product is an International compatibility.”

The Superior single piece through shaft design in One-piece body is a reliable and long-life solution for difficult conditions. Valves are with light weight and ideal economic solution for general purpose applications. Lugged valve gives alternative solution where flanged valves are considered and restrictions of space and cost. The Replaceable Seat design isolates the line media connection from body and stem. Replaceable seat design with inbuild molded O-ring eliminates the need for gaskets between the flanges and the valve. Also serve as the flange gasket to make valve more capable. Seat is convenient and economical for field replacement. Sealing is formed by preloaded contact between disc and seat. Shaft seal is suitable for pressure-vacuum service which is also self-adjustable, non-corrosive and heavy duty to absorb the thrust and extends valve cycle life. The Disc hub-edge profile is spherically machined and rounded manually with polishing to provide full concentric seating without obstruction to flow which gives maximum seat life, minimum torque and bubble tight shut-off. Disc-Screw connection with disc is positive, stronger and allows quick and easy disassembly.- Design standard as per EN 593 or API 609 as standard, Another applicable standard on request.

- Testing standard as per API 598 or BS EN 12266-I as standard. bubble tight shut off valve.

- Certificate EN10204 Type 3.1 as standard & Manufacturing under Quality system ISO 9001: 2015.

- Casting inspection as per MSS-SP-55 as standard. Another applicable standard on request.

- Trims available with combination of various Casting material like CI/ DI/ NICI/ NIDI/ WCB/ CF8/ CF8M/ CF3M/ GR. 4A-5A / NAB etc. and Seat Material like EPDM / BUNA-N / VITON etc. Various Coating, Bonding and Lining as per Customer requirement.

- Disc Design is also available without Disc Screw, as per customer requirement.

- 100% factory tested (Hydro, Pneumatic) and Inspected valves as per standard.

- Lever / Gear / Pneumatic / Electric Operation as per customer requirement.

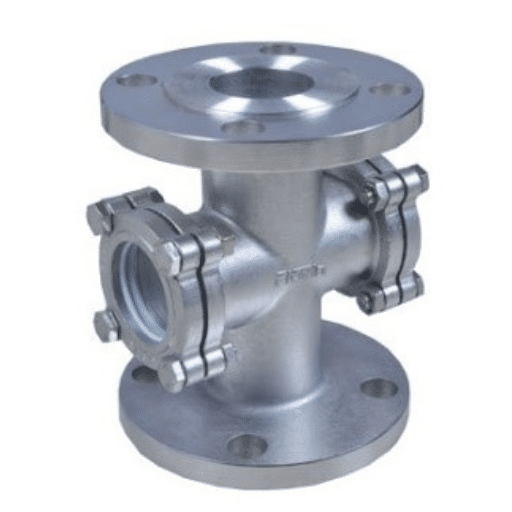

Full View Sight Glass (PN10)

Applications:

Industrial facilities, oil refineries, bath soap manufacturing plane, gas industries, petrochemical complex, high viscous process media, building construction, environmental water treatments, synthetics, plastic and resin industries, polymer manufacturing plant, food industries (chocolate, sauce etc.), fertilizer industries etc.Technical Data :

| Design Std. | As per BS 5352 |

| Testing Std. | As per API 598 |

| End Connection | As per ANSI B16.5 |

| Size | ½” to 4” (15 mm to100 mm) |

| Pressure rating | PN10 |

| Maximum working pressure | 10 Kg/cm2 |

| Test pressure | 15 Kg/cm2 |

Dimensions

| Size | A | B | C |

| 15 | 153 | 51 | 137 |

| 20 | 153 | 51 | 137 |

| 25 | 153 | 51 | 137 |

| 40 | 178 | 64 | 146 |

| 50 | 190 | 76 | 190 |

| 75 | 229 | 102 | 132 |

| 100 | 299 | 127 | 283 |

All dimensions are in mm.

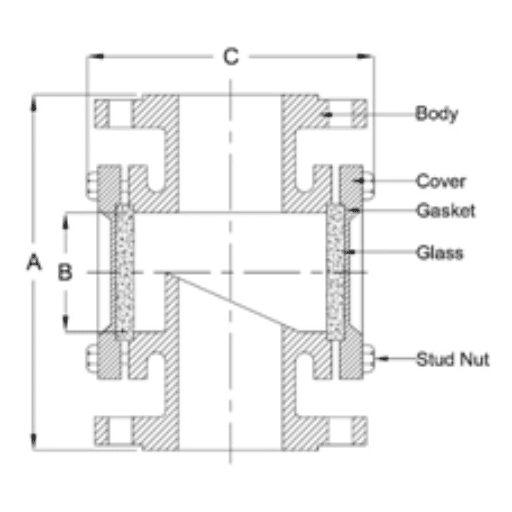

Double Window Sight Glass (PN10, PN16)

Applications:

Industrial facilities, oil refineries, bath soap manufacturing plane, gas industries, petrochemical complex, high viscous process media, building construction, environmental water treatments, synthetics, plastic and resin industries, polymer manufacturing plant, food industries (chocolate, sauce etc.), fertilizer industries etc.Technical Data :

| Design Std. | As per BS 5352 |

| Testing Std. | As per API 598 |

| End Connection | As per ANSI B16.5 |

| Size | 1/2” to 6” (15 mm to150 mm) |

| Size | 2" to 18", Class 150, 300 |

| Pressure rating | PN10 / PN16 |

| Maximum working pressure | 10 Kg/cm2 |

| Test pressure | 20 Kg/cm2 |

Dimensions

| Size | A | B | C |

| 15 | 153 | 51 | 137 |

| 20 | 153 | 51 | 137 |

| 25 | 153 | 51 | 137 |

| 40 | 178 | 64 | 146 |

| 50 | 190 | 76 | 190 |

| 75 | 229 | 102 | 232 |

| 100 | 299 | 127 | 283 |

| 150 | 406 | 191 | 368 |

All dimensions are in mm.