Product Range

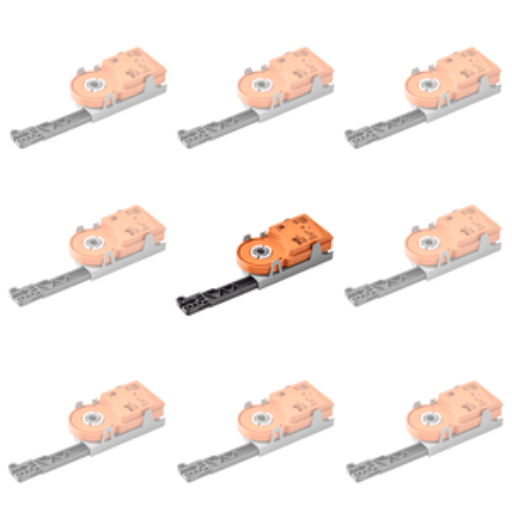

Belimo Linear Damper Actuators

Applications

Linear damper actuators are available with a variety of stroke lengths to meet specific application requirements.Efficient Push and Pull

Belimo linear damper actuators are available with stroke lengths of 100, 200 or 300mm and on/off, floating point or modulating control. The comprehensive range of 150 N force to 450 N force are ideal for a wide range of applications such as louvres, diffusers, greenhouse windows and anywhere linear motion is required.

Powerful Linear Motion

Whether mounted horizontal or vertical, the actuator delivers a linear push or pull motion providing reliable and efficient performance for louvres, diffusers, skylights, greenhouse windows, or when retrofitting a system. Linear actuators offer simple installation, cost effective operation and flexible commissioning options.

Specification

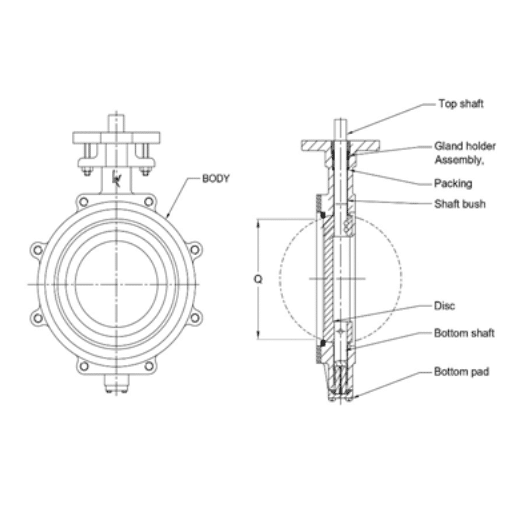

Force (N): 50 N, 100 N, 150 N Stroke: 60 mm: 100 mm Voltage AC/DC: 120 V, 230 V, 24 V Control type: Open/close, 3-point, Modulating Running time: 2.5...19 s, 50...79 s, 100...150 s Electrical connection: Cable, Connector plugBUTTERFLY VALVE High Performance Double Offset

Applications :

Pharma, Military, Sour gas, Food Processing, Vacuum and Oxygen services, Steam services, Dead-end services, Fire, Chemical industry e.g. Chlorine-Ammonia etc., Reverse Osmosis, Slurry services, Modulating or Special fluids where Flow control is Important.TECHNICAL DATA

Size: 2” (50 mm) to 36” (900 mm)

Type: Wafer, Lug, Flange Design: Eccentric-Double offset Pressure: ANSI Class 150-300 Seat: RTFE, PTFE, UHMWPE, Metal, Fire Safe Flange Suit To: ANSI 150#,300#Design, Manufacturing and Testing Standards – Technology at a Glance

Kansei Wafer, Lug and Flanged Double offset butterfly valves are designed to ensure minimum seat wear, zero leakage shutoff throughout the full pressure range and Uni-Bidirectional to provide a long service life with minimum maintenance. “A major advantage of Kansei product is an International compatibility.”

The Superior two-piece stem design and double offset disc/stem design allows high cycling and eliminates seat deformation when the disc is in the open position. At the initial point of disc opening, the offset disc produces a cam action and pulling the disc from the seat. During opening, disc does not contact the seat which ensures the maximum seat service life with reduced operating torques. The first offset is by locating the stems downstream of the center line of the seat which allows 360-degree unobstructed sealing surface. The second offset is by locating the stems off-center of the vertical axis of the seat. As the valve closes, the camming action converts the rotary motion of the disc to a linear motion which effectively push the disc on seat. Mounting pads integrally casted which provides direct mounting of Gear box and Actuators on valves. Torque requirements of the Kansei High performance double offset valve is significantly lower. The seat is completely isolated from all contact with the line media which allows superior performance of valve with extended service life. Serrations of the seat retainer ring and body secure the seat assembly in place irrespective of disc position. Line media seals to Zero-leakage in both directions and seat is self-adjusting to absorb wear and temperature changes. Replacement of seat is also easy without disturbing the disc or stem. The seat design in such a way to ensure seal drop-tight and bi-directional at low to high pressure range. Seat incorporates a Stainless-Steel wire winding with U-shape envelope to provide better seat life. The wire allows flexibility in both direction of flow. Fire safe: Kansei High performance double offset valves having firesafe seat design options in wafer, lug and flange valves. Fire safe design combines superior performance, extended service life. In normal service, the fire safe design with Soft seat and Metal seat to ensure zero-leakage in both directions of line media flow in full rated pressure and temperature range. In the fire condition, soft seat will be destroyed either partially or fully by excessive heat and metal seat will take place to provide constant sealing. Fire safe packing arrangement with three rings of graphite to create a superior and high temperature sealing.- Design standard as per EN 593 or API 609 (cat. B) as standard, another applicable standard on request.

- Testing standard as per API 598 and FCI 70-2.

- Certificate EN10204 Type 3.1 as standard & Manufacturing under Quality system ISO 9001: 2015.

- Casting inspection as per MSS-SP-55 as standard. Another applicable standard on request.

- Trims available with combination of various Casting material like WCB/ CF8/ CF8M/ CF3M/ GR. 4A-5A/ NAB/ Aluminum Alloys etc. and Seat Material like RTEF/ PTFE/ UHMWPE/ METAL/ FIRE SAFE.

- 100% factory tested (Hydro, Pneumatic) and Inspected valves as per standard.

Greenheck Volume control dampers ( VCD )

Description

Control dampers regulate the flow of air in an HVAC system for intake, exhaust, or mixed air applications.

OVERVIEW

VCD

Volume control dampers are for use in HVAC systems requiring modulating airflow. VCD dampers can be used in applications as an automatic control damper with low to medium pressure and velocity systems. Units feature a blade design, which maximizes free area, increasing damper performance.

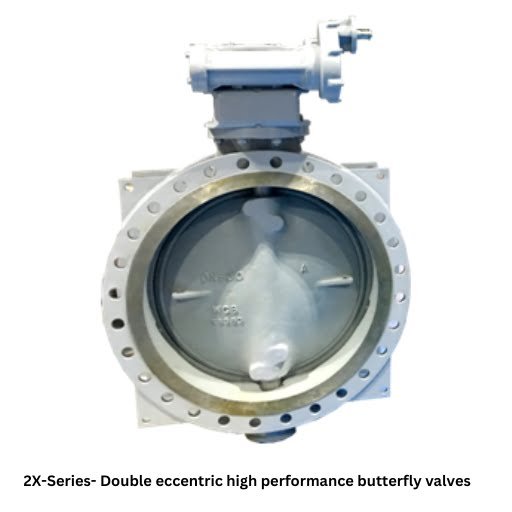

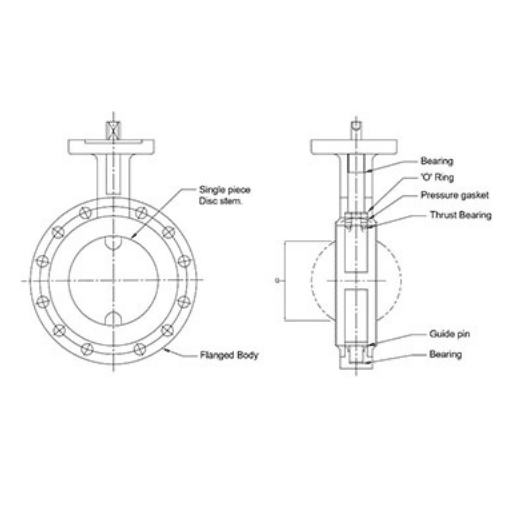

2X-Series- Double eccentric high performance butterfly valves – V-TORK CONTROLS

Butterfly Valves

V-TORK Butterfly Valves are well suited for handling larger flow of Liquids and gases alternately of low pressure and for handling of liquids with suspended solids (Slurries).

2X SERIES

Specifications

- Size: 2” to 50” (40mm to 1200mm)

- Wafer, Lug, Flanged End

- Class #150.

- Double Eccentric Type

- Standard: BS 5155

Fabricated Valves as per customer requirement.

Applications:

Range of Material of Construction Disc: WCB / CF8 / CF8M / DI / CI & any special metallurgy on customer request; Stem: AISI 410 / 304 / 316; Body: CI / WCB / CF8 / CF8M Range of Seat Materials EPDM / Viton / Natural Rubber / Nitrile /PTFE /Metal Seat Range of Actuators Manual – Lever Operated, Gear Operated, Pneumatic Actuated, Motorized with Complete AutomationArmstrong 4300 vertical in-line pumps

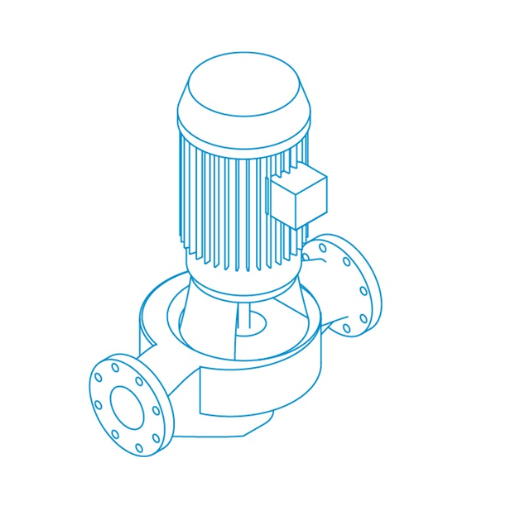

- Applications-HVAC-system pumping; light industrial/ process pumping (water or glycol based)

- Description-The Armstrong 4300 pipe-mounted pumps are designed for space-saving installation, high operating efficiency, and long service life

- Materials(MOC)-Cast, ductile iron or bronze casing, Cast iron or bronze impeller

- Configuration-Outside balanced or inside single spring mechanical seal

- Performance range-Up to 28,000 USgpm (1,800 L/s) Flow; up to 500 ft (150 m) Head

- Temperature-300oF (150oC)

- Power Range-1 hp to 1250 hp (0.75 kW to 900 kW)

- Size-1.5″ to 20” (40 mm to 500 mm)

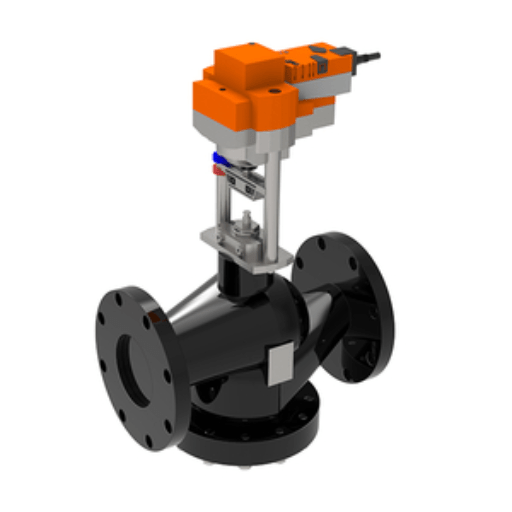

Belimo Globe Valves

Applications

The Globe valve series are available in DN 15 to DN 250 with both threaded and flanged end fittings to meet the requirements of various applications, incl. high pressures and high temperatures.Greater Force and Flexibility

The globe valve series are available in sizes from DN15 - 150 which fulfil the requirements of PN16 and PN25 applications. Utilising either bronze or stainless steel trim and fitted with either spring return, non-spring return, or electronic fail-safe actuators, globe valves are the perfect fit for HVAC equipment such as air handling units, terminal equipment, and hydronic systems with primary and secondary loops of water or steam service.

More Strength for Higher Pressure Demands

The Belimo globe valve actuators are designed to withstand the rigorous demands of many HVAC applications. With its innovative quick connect coupler, the globe valve actuator can be retrofitted and installed and adapted in no time.

Specification

Pattern: 2-way, 3-way Valve operations mode: Diverting, Mixing, Mixing/Diverting PN: 16, 25 kvs range (kvs): 1.1...3.0 kvs, 3.1...6.5 kvs, 6.6...14 kvs, 15...40 kvs, 41...170 kvs, 171...1000 kvs Valve size (mm): 15 mm, 20 mm, 25 mm, 32 mm, 40 mm, 50 mm, 65 mm, 80 mm, 100 mm, 125 mm, 150 mm, 200 mm, 250 mm Pipe connection: Flange, Internal threadMODY ELECTRICAL SUBMERSIBLE DEWATERING PUMP

DESIGN ADVANTAGES

- Stainless Steel Strainer, Shaft, Impeller, Outlet and Hardware for maximum corrosion resistance.

- S$S316 impeller for seawater and corrosive application.

- Tandem Tungsten Carbide/ Silicon Carbide and Tungsten Carbide/Silicon Carbide mechanical seals.

- Mechanical Seals in wholly enclosed pressure compensated oil chamber.

- Field adjustable Nitrile Rubber-lined Diffuser/Wear Plate Optimizes efficiency throughout the life of the pump.

- Equipped with Sacrificial Zinc Anodes for maximum life in a saline Fluid environment.

- Viton Elastomers.

- Thermal Overload Protection

- 2.5" instantaneous coupling for quick fixing. NOTE:

- Pumps complies to IP 68 Dewatering pumps are available up to 1000 TPH

- Complies to Shock Grade “B / NSS II” Also available in Stainless Steel MOC

- Mould (Fungus) Growth Test as per JSS 55555.

Adept Ultrasonic Flowmeter – UFM 6740

Battery Powered Water Meter

Based on Transit Time technology

Based on Transit Time technology

Battery powered with 5 years life

Battery powered with 5 years life

Field interchangeable electronics

Field interchangeable electronics

Unique IP 68 rated transmitter housing

Unique IP 68 rated transmitter housing

Flow tube sizes 15 mm to 600 mm

Flow tube sizes 15 mm to 600 mm

Integral or remote transmitter

Integral or remote transmitter

GSM or GPRS AMR functionality

GSM or GPRS AMR functionality

High long-term stability and reliability

High long-term stability and reliability

Process industries

Process industries

Dredging industries

Dredging industries

Water and waste water management

Water and waste water management

Mining industries

Mining industries

Introduction

Adept UFM 6740 inline type Flanged Battery Operated Ultrasonic Flowmeter provides abundant capabilities for accurate liquid flow measurement. It is widely used in remote location applications where Field Electric supply is not available.

Salient Features

Applications

Product Selection Guide

| Parameters | Specifications |

|---|---|

| Technical characteristics | Low power consumption, digital process technology with stable piezoelectric sensor |

| Accuracy | ±1% of reading (Optional ±0.5%) |

| Repeatability | 0.2% of Span |

| Display | Total flow, flow rate, velocity, working time & date, signal intensity, quality & battery status |

| Output | RS 485, 4 – 20 mA, Pulse for total flow (All outputs need external power supply 24 V DC) |

| Communication interface | GSM, RS 485 (Modbus RTU), UART |

| Operation | Inside keypad available |

| Sampling period | 0.5 sec |

| Environment temp. | Up to 65°C |

| Water temp. | 5 to 70°C |

| Power supply | Li-ion battery, solar powered |

| Enclosure class | IP 68 |

| Pipe size | DN 40 – 600 |

| Flange standard | ANSI, IS, DIN PN, BS |

| Pressure transmitter | Range 0-16 kg/cm², IP 68, 1/2″ male threaded, accuracy 0.25% |

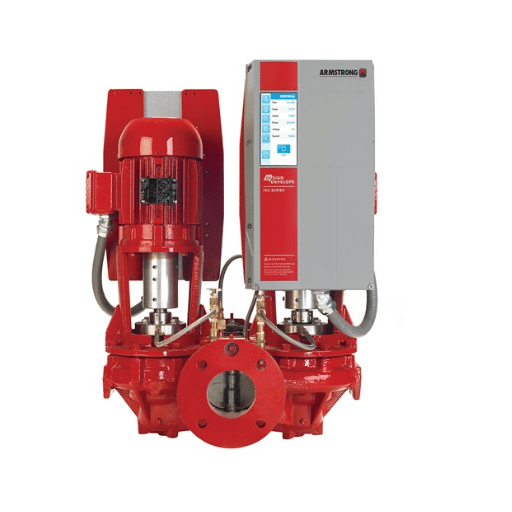

Armstrong Design Envelope 4302 Dualarm Pumps

- Applications-HVAC system pumping; general purpose pumping; industrial/process pumping (water or glycol based) Armstrong Design Envelope Pumps with integrated controllers are OSHPD pre-approved!

- Description-Pipe-mounted 2-pump unit with integrated intelligent controls for space-saving installation, superior energy performance, and full redundancy or parallel-pumping operation. Saves up to 75% in energy over comparable traditional constant speed or variable frequency operated pump installations.

- Materials (MOC)-Cast iron or ductile iron casing, Cast iron or bronze impeller, Sintered silicon carbide mechanical seal

- Configuration-On-board Intelligent Variable Speed controls with Sensorless or Parallel Sensorless control. Controls enclosure UL type 12 or UL type 4X (outdoor applications). Available with NEMA premium motors. Outside balanced or inside single spring mechanical seal

- Performance range-Up to 1250 USgpm flow and 250 ft head (80 L/s, 76 m)

- Temperature-250°F (121°C)

- Power Range-0.33 hp to 75 hp (0.25 kW to 55 kW)

- Size –1″ to 8” (25 mm to 200 mm)

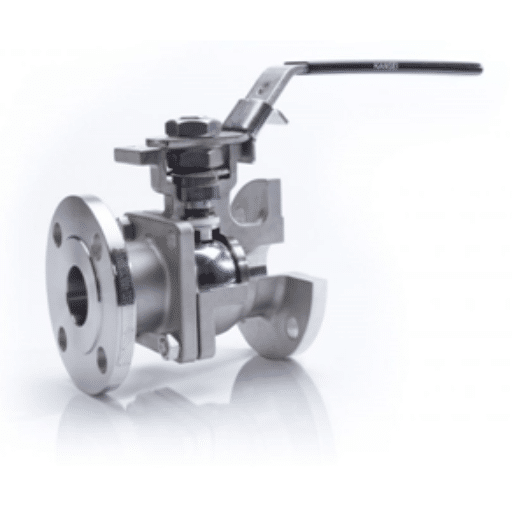

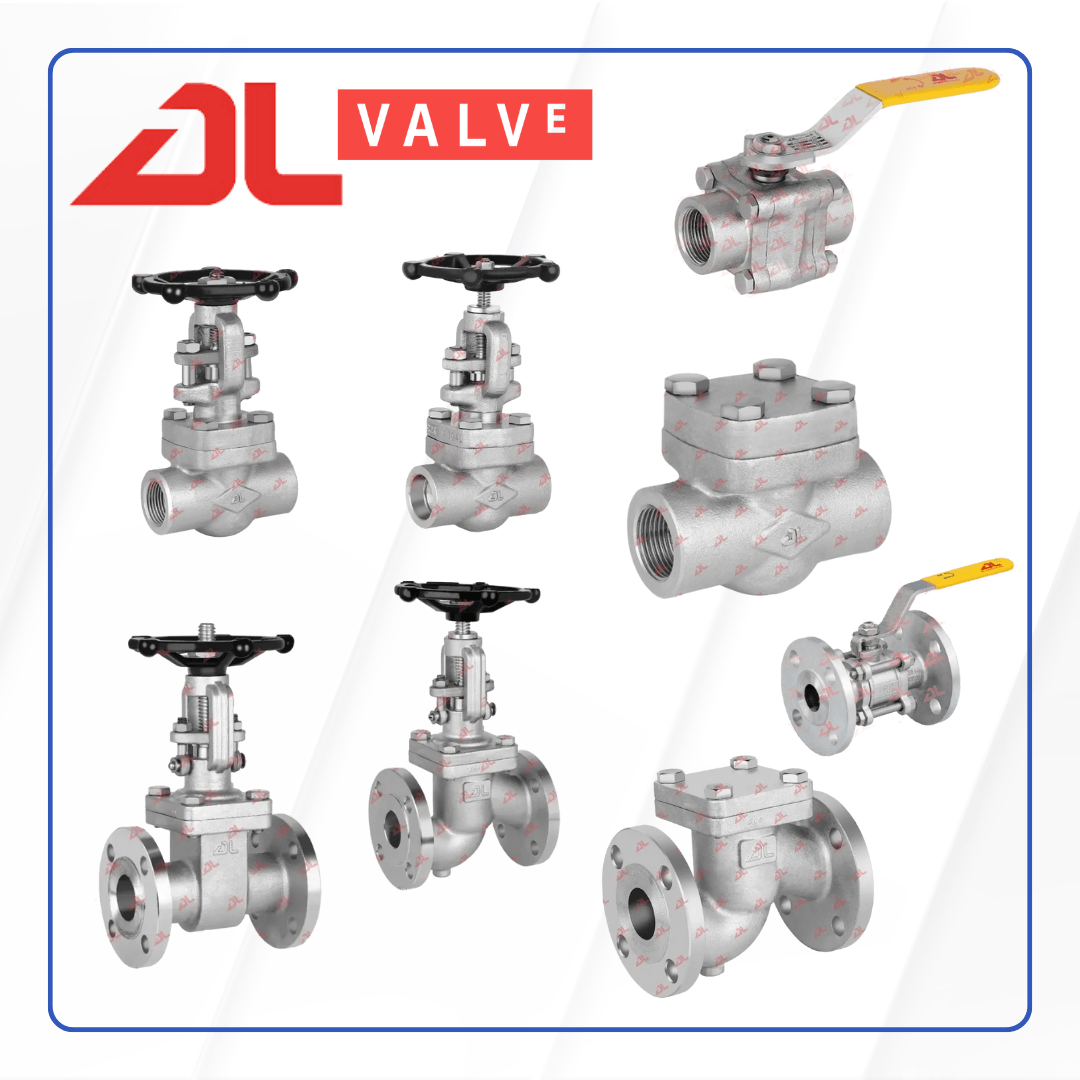

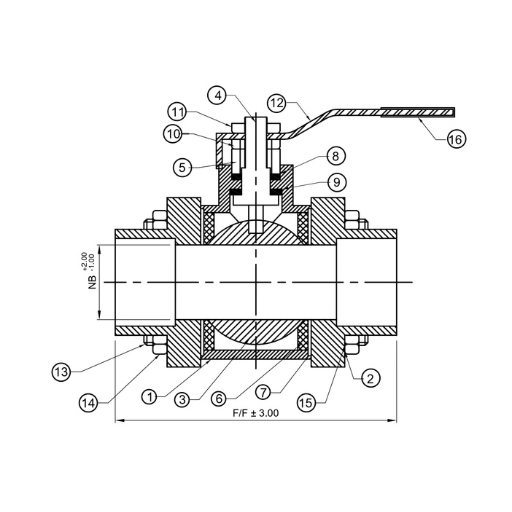

Ball Valves Three Piece, Full Bore (Screw End, Socket Weld) (150#, 300#, 600#, 800#)

Technical Data :

| Design Std. | As per ISO 17292 & BS 5351 |

| End Connection | Screwed End/Socket Weld |

| Testing & Std. | As per API 598 / ISO 5208 |

| Size, 150# | 15 mm to 50 mm (1/2" to 2") |

Material (MOC)

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Adaptor | WCB / CF8 / CF8M |

| 3 | Ball | CF8 / CF8M |

| 4 | Steam | SS304 / SS316 |

| 5 | Gland | SS304 / SS316 |

| 6 | Seat Ring | PTFE / GFT /CFT |

| 7 | Body Seal | PTFE / GFT /CFT |

| 8 | Gland Packing | PTFE / GFT /CFT |

| 9 | Steam Seal | PTFE / GFT /CFT |

| 10 | Gland Nut | MS/SS304 |

| 11 | Lever Nut | MS/SS304 |

| 12 | Lever | MS/SS |

| 13 | Stud | MS/SS304 |

| 14 | Stud Nut | MS/SS304 |

| 15 | Stud Washer | MS/SS304 |

| 16 | Lever Sleeve | PVC |

Dimensions 150#

| Size | NB | F/F | Thread Type |

| 15 | 12.5 | 62.5 | BSP/NPT/SW |

| 20 | 19.0 | 74.0 | BSP/NPT/SW |

| 25 | 25.0 | 87.0 | BSP/NPT/SW |

| 40 | 38.0 | 109.0 | BSP/NPT/SW |

| 50 | 50.0 | 110.0 | BSP/NPT/SW |

All Dimensions are in mm

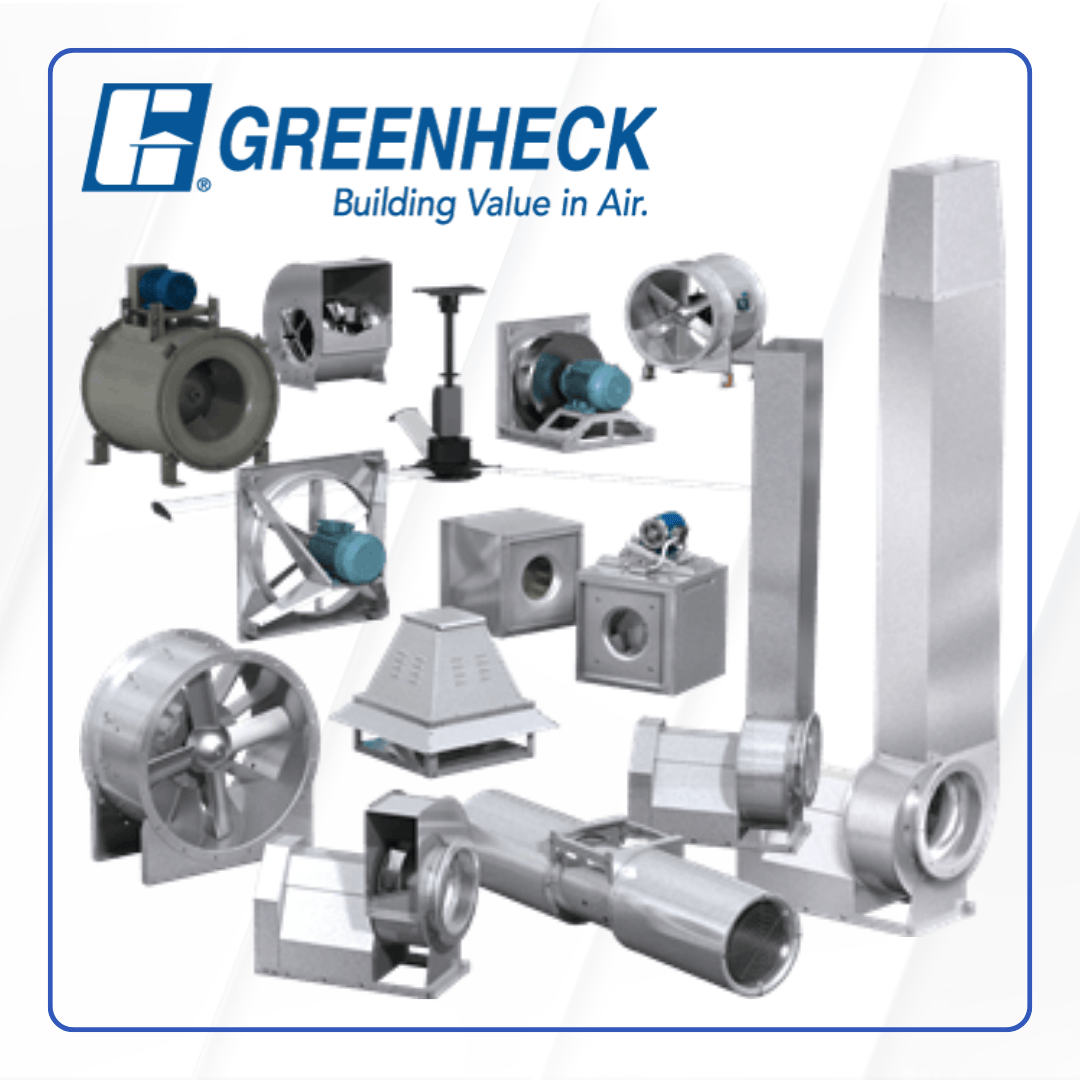

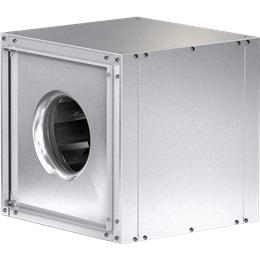

Greenheck Inline Fans

Description

Inline fan models meet a wide range of supply or exhaust applications in commercial and industrial facilities. There are models available for clean air, sound sensitive and heavy-duty industrial applications.

OVERVIEW

BSQ-M

Model BSQ-M is a belt drive, centrifugal inline fan for clean air applications including intake, exhaust, return, or make-up air systems where space is a prime consideration. Units feature removable side panels for easy access for inspection and service.

- Fan diameters range from 70mm up to 420mm

- Capacities up to 45193 CMH (26600 CFM)

- Up to 956 Pa (3.8 in. wg)

Certifications:

AMCA Sound and Air

QEI-M

The QEI-M is a mixed flow fan for commercial, institutional, and industrial applications handling everything from clean air to high temperature exhaust. Model offers multiple construction levels to match the application providing best performance at the most economical solution. Features performance enhancing airflow straightening vanes and easily accessible motor outside of the airstream. The QEI-M model has a variety of mounting options for indoor and outdoor locations.

- Capacities up to 55,900 cmh (32,900 cfm)

- Up to 1,244 Pa (5 in. wg)

- Chemical resistant coated steel

SQ-M

Model SQ-M is a direct drive, centrifugal inline fan for clean air applications including intake, exhaust, return, or make-up air systems where space is a prime consideration. Units feature removable side panels for easy access for inspection and service.

- Fan diameters range from 70mm up to 160mm

- Capacities range up to 8536 CMH (5025 CFM)

- Up to 436 Pa (1.75 in. wg)

Certifications:

AMCA Sound and Air

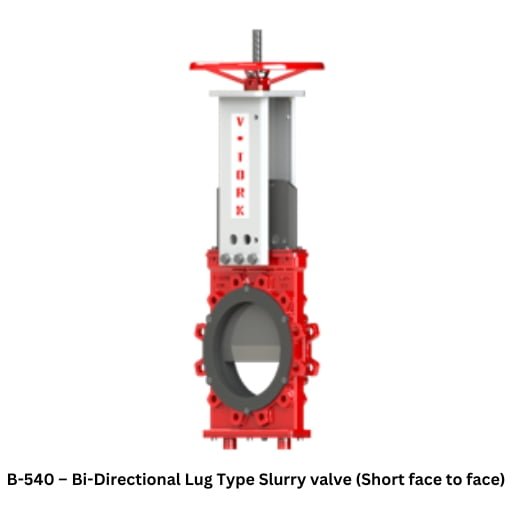

B-540 – Bi-Directional Lug Type Slurry valve (Short face to face) Knife Gate Valves – V-TORK CONTROLS

B-540

Specifications

- Bi Directional, Lug Type

- Size 2” to 54” (50mm to 1350mm)

- Dual Elastomer Seals with Retainer Rings

- Single Piece Construction

- 150 PSI/300 PSI (18” to 54”) CWP

- Standard: V-TORK Std

Applications:

Liquid/Slurry Application: Abrasive Slurries in Mineral Industries, Pulp Slurry, Chemical Slurry, Molasses, Raw Water Intake, Ash Slurries in Thermal Power Plant, Chemical Slurries in Chemical Process Industries, Sugar Juice in Sugar Industries Bulk Handling (Solids & Powders): Pneumatic Conveying systems, Detergent Powders/Cake, Boiler bed ash, Carbon Black, Coal handling, Lime powder handling applications. Gas Application: Blast Furnace Gas in Steel industries, Pulverized coal fired lines in Thermal Power Plants, Hot gas handling. Powder Applications: Lime powder, Silica/ Magnesium Oxide/ Calcium Oxide/ Al Oxide/ Zyconium Oxide. Range of Material of Construction DI / WCB & Special Materials on Request Range of Seat Materials EPDM /Natural Rubber (Special material on request) Range of Actuators Hand Wheel, Lever Operated, Chain Wheel, Bevel Gear, Pneumatic Double Acting/Single Acting Cylinder, Hydraulic Cylinder, Electro-Pneumatic Operation, Motorized Range of Accessories Solenoid Valve, Limit Switch, Proximity Switch, Junction Box, Positioner, Accumulator for Emergency Shut Off, Wear Rings, AFR, Speed Control Valves, Reed Limit Switch. Range of Addl. Features Purge Port, Drain Port, Stem Extension, Fail Safe System, Locking Arrangement, Non-Raising Stem arrangement…Forged Gate Valve

Product Description

| 1/4" to 2” (8mm to 50mm) | |

| Class | 150#, 300#, 600#, 800#, 900#, 1500#, 2500# |

| Bore | Reduce Bore (Standard Bore), Full Bore |

| Design Standard | API 602 |

| Pressure / Temp. | ASME B 16.34 |

| Testing Std. | API 598 |

| Construction | Bolted Bonnet / Pressure Seal Bonnet (Welded Bonnet) |

| End Connection | Socket Weld, Screwed NPT, Screwed BSP, Flanged RF, Flanged RTJ, Butt-Weld, Nipple Extended (Pup Piece) |

| Operation | Hand Wheel |

| Material | A105N, LF2, F304L, F316L, F317, F321, F347,F5, F9, F11, F22, F91, F51, F53, F55, F60, Inconel, Monel, Alloy 20, Nickel Aluminium Bronze |

Belimo Fire Damper Actuators

Applications

Specifically designed safety actuators for the motorisation of fire dampers provide best protection against the spread of fire and smoke through the air ducts.Technology that Saves Lives

Belimo fire and smoke damper actuators are designed for operation in smoke and combination fire and smoke dampers in ventilation and air-conditioning systems with a torque range from 2 Nm to 40 Nm @ 177°C. For maximum safety in all situations, the fire and smoke actuators meet all codes for commercial buildings in the U.S., pass UL 555 and UL 555S at 177ºC and are tested for 30,000 open-closed cycles with approved dampers. Belimo fire and smoke damper actuators exceed UL’s requirement of 20,000 cycles at damper static load.

Safety in Buildings

Belimo fire and smoke damper actuators have an extensive torque range specifically designed for operation with fire, smoke, and combination fire and smoke dampers in ventilation and air-conditioning systems. As an integral part of the life safety system, Belimo fire and smoke actuators provide high performance, low power consumption, and are compliant with Life Safety Codes and Standards.

Specification

Torque (Nm): 2 Nm, 3.5 Nm, 4 Nm, 8 Nm, 9 Nm, 18 Nm, 20 Nm Voltage AC/DC: 120 V, 230 V, 24 V Control type: Open/close, Modulating Electrical connection: Cable, Cable with connector plug,Leads Thermoelectric tripping device: BAT (72°C)BUTTERFLY VALVE PFA/PTFE Lined, Centric Bi-directional

Applications :

This type of valves are used for multitude and corrosive application, Hazardous and pure liquid, gas, & vapors, free flowing. e.g.: Pharma, foundries and mining, chemicals and petrochemicals, pulp and paper industries, under vessels, & specially used where constant torque and no maintenance is required . Suitable for on-off and control servicesTECHNICAL DATA

Type: Wafer type, Lug type, Flange typeWafer type & Lug type Size: 2” (50 mm) to 12” (300 mm)

Flange type Size: 14” (350 mm) to 16” (400 mm) Design: Centric Bi-directional Pressure: PN10, PN16 Seat: PTFE, PFA, PFA CONDUCTIVE, TFM, TFM CONDUCTIVE Flange Suit To: ANSI 150#Design, Manufacturing and Testing Standards – Technology at a Glance

Kansei PFA/PTFE Lined Centric Bi-directional Butterfly valves are designed to ensure a tight fit around the disc for bubble tight shut off in both direction and provide a constant torque with no maintenance. “A major advantage of Kansei product is an International compatibility.”

The Exceptional Design of one-piece thin disc stem lined with 3mm molded PFA providing high Kv value. The liner and disc are the only two valve parts in contact with the medium. Kansei improved design of disc leading to less deflection at higher pressure and tighter in line seal and for stem sealing system. Primary shaft sealing by preloaded contact between disc and liner hub and the secondary shaft seal by oversizing the shaft diameter in relation to the shaft hole in the liner. The liner and disc are molded and machined to close tolerances to provide low torque, less stress and deformation using opening and closing. PTFE atmospheric seat protects internal components from atmospheric corrosion and provides locating ring for actuator mounting. Fully encapsulated bottom shaft eliminates potential leak path at bottom of valve and eliminates the necessity for further sealing elements- Design standard as per EN 593 or API 609 as standard, another applicable standard on request.

- Testing standard as per API 598 or BS EN 12266-I as standard. 100% bubble tight shut off valve.

- Certificate EN10204 Type 3.1 as standard & Manufacturing under Quality system ISO 9001: 2015.

- Casting inspection as per MSS-SP-55 as standard. Another applicable standard on request.

- Trims available with combination of various Casting material like CI/ DI/ WCB/ CF8M/ CF3M/ GR. 4A-5A/ etc. and Seat Material PTFE.

- 100% factory tested (Hydro, Pneumatic) and Inspected valves as per standard.

- Lever / Gear / Pneumatic / Electric Operation as per customer requirement.

Greenheck MANUAL BALANCING DAMPERS

Description

Balancing dampers are control dampers that balance the flow of air in an HVAC system. The intended applications for these dampers do not include a positive shutoff or for automatic control. The MBD series are shipped manual hand quadrants that can lock in place.

OVERVIEW

MBD-15

The MBD-15 is a multi-blade manual balancing damper regulating the flow of air in an HVAC system.

- Blade Type: 3V

- Pressure: Up to 1.0 Kpa (4 in. wg)

- Velocity: Up to 10.16 m/s (2000 fpm)

- Temperature: Up to 82°C (180°F)

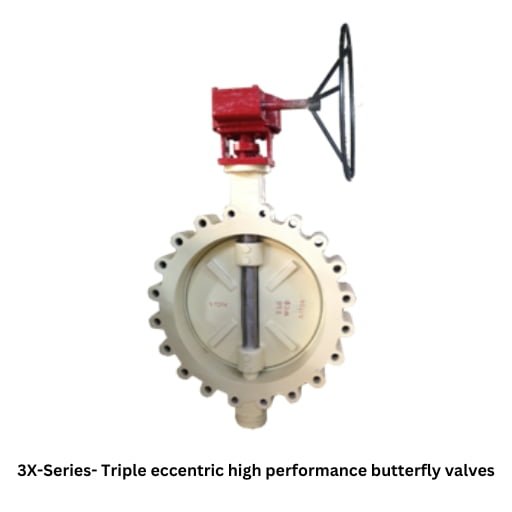

3X-Series- Triple eccentric high performance Butterfly Valves – V-TORK CONTROLS

3X SERIES

V-TORK Butterfly Valves are well suited for handling larger flow of liquids and gases alternately of low pressure and for handling of liquids with suspended solids (Slurries).Specifications

- Size: 2” to 50” (40mm to 1200mm)

- Wafer, Lug, Flanged End

- Class #150.

- Double Tripple Type

- Standard: BS 5155

Fabricated Valves as per customer requirement.

Applications:

Range of Material of Construction Disc: WCB / CF8 / CF8M / DI / CI & any special metallurgy on customer request; Stem: AISI 410 / 304 / 316; Body: CI / WCB / CF8 / CF8M Range of Seat Materials EPDM / Viton / Natural Rubber / Nitrile /PTFE/Metal Seat Range of Actuators Manual – Lever Operated, Gear Operated, Pneumatic Actuated, Motorized with Complete AutomationArmstrong 4380 vertical in-line pumps

- Applications-HVAC-system pumping; light industrial/ process pumping. (water or glycol based)

- Description-The Armstrong 4380 pipe-mounted pumps are designed for space-saving installation and long service life.

- Materials(MOC)-Cast iron or ductile iron casing, Silicon sintered carbide mechanical seal, Cast iron or bronze impeller.

- Configuration-Inside single-spring mechanical seal.

- Performance range-Up to 2,500 USgpm (160 L/s) flow; up to 300 ft (90 m) head

- Temperature-250°F (121°C)

- Power Range-0.33 hp to 60 hp (0.25 kW to 45 kW)

- Size-1.5″ to 8″ (40 mm to 200 mm)

Belimo Duct Sensors (T/RH)

Applications

Belimo offers a wide range of air duct sensors covering all standard measurement values: temperature, humidity, dew point, CO₂, VOC’s, pressure and frost detection.Providing the Reliability, You Know and Expect

Belimo offers a line of duct sensors covering measurement values for temperature, humidity, enthalpy, dew point, CO₂, VOC’s, pressure, and low temperature limit detection backed with UL certification and a 5-year warranty.

Accurate Reading

Belimo duct sensors offer a snap-on NEMA 4X, IP 65 enclosure for easy installation and commissioning, field selectable ranges, high accuracy and reliability, self-calibration features, and mounted accessories are included.

Specification

Measured values: Temperature, Frost, Safety temperature, Humidity, Condensation, CO₂, VOC, Differential pressure, Volumetric flow Output signal: 0...5 V, 0...10 V, 4...20 mA, Switch, Modbus, BACnet, Pt100, Pt1000, Ni1000, Ni1000TK5000, NTC10k (10k2), NTC10k Pre (10k3), NTC10k Carel, NTC20k Measuring range temperature (°C): -50...150 °C, -50...160 °C, -50...250 °C, -40...80 °C, -35...70 °C, -35...100 °C, -10...15 °C, 0...15 °C, 0...50 °C, 30...90 °C, 50...80 °C, 70...130 °C Measuring range pressure (Pa): -150...250 Pa, -100...2500 Pa, 0...7000 Pa, 20...300 Pa, 50...500 Pa, 200...1000 Pa, 500...2500 Pa, 1000...5000 Pa Mounting type: Average, Single point, Immersion Probe length: 50 mm, 100 mm, 140 mm, 150 mm, 156 mm, 180 mm, 200 mm, 270 mm, 300 mm, 450 mm, 3 m, 6 m Additional features: Manual reset, Auto reset, Auto or manual reset, Internal sensor, External sensor, Auto-Zero, 2 measuring systems Display type: LCD, LEDMODY SUBMERSIBLE GRINDER PUMPS

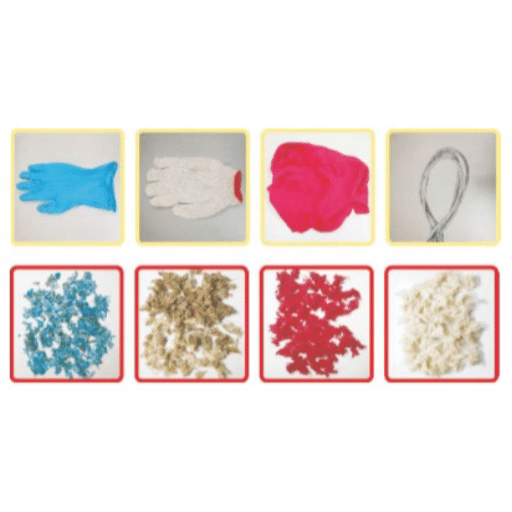

MGD series Grinder Pumps are specially designed and produced to handle waste waters from Industries like Textile, Leather tanneries, Hospitals , Hotel, Residential colonies where fibrous material forms part of the waste water. As these material obstruct discharge likes or often choke the pumps , MGD pumps becomes ideal choice.

The Global Pump GST line handles a wide range of liquids from water and sewage to sludge that can contain solids and other material with flows up to 16,000 gpm (3,634 m°/h) and heads up to 202 feet (62 m). Industry best in fuel efficiency, ease-of-maintenance, and durability.