Showing 49–60 of 131 results

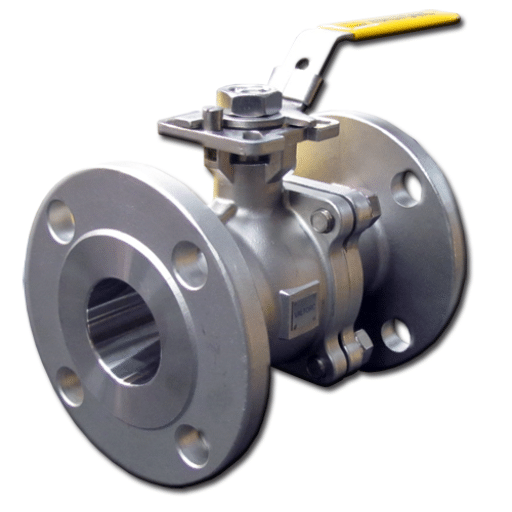

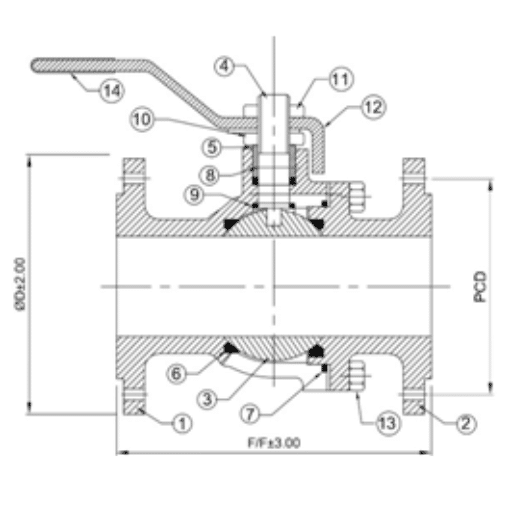

Ball Valves Three Piece, Full Bore, Flange end (150#, 300#)

Technical Data :

| Design Std. | As per ISO 17292 & BS 5351 |

| End Connection | Flanged End |

| Testing Std. | As per API 598 or ISO 5208 |

| Size 150# & 300# | 15 mm to 300 mm (1/2" to 12") |

MATERIALS (MOC)

| Sr. No. | Description | Material |

| 1 | Body | CI /WCB / CF8 / CF8M |

| 2 | Adaptor | CI / WCB / CF8 / CF8M |

| 3 | Ball | CF8 / CF8M |

| 4 | Stem | SS304 / SS316 |

| 5 | Gland | SS304 / SS316 |

| 6 | Seat Ring | PTFE / GFT / CFT |

| 7 | Body Seal | PTFE / GFT / CFT |

| 8 | Gland Packing | PTFE / GFT / CFT |

| 9 | Stem Seal | PTFE / GFT / CFT |

| 10 | Gland Nut | MS / SS304 |

| 11 | Lever Nut | MS / SS304 |

| 12 | Lever | MS / SS |

| 13 | Stud | Ms / SS304 |

| 14 | Stud Nut | Ms / SS304 |

| 15 | Stud Washer | Ms / SS304 |

| 16 | Lever Washer | PVC |

DIMENSIONS 150#

| Size | Dia D | PCD | F/F |

| 15 | 90 | 60.5 | 108 |

| 20 | 100 | 70 | 117 |

| 25 | 110 | 79.5 | 127 |

| 40 | 125 | 98.5 | 165 |

| 50 | 150 | 120.5 | 178 |

| 65 | 180 | 139.5 | 191 |

| 80 | 190 | 152.5 | 203 |

| 100 | 230 | 190.5 | 229 |

| 150 | 280 | 241.5 | 267 |

| 200 | 345 | 298.5 | 292 |

| 250 | 405 | 362 | 330 |

| 300 | 485 | 432 | 356 |

DIMENSIONS 300#

| Size | Dia D | PCD | F/F |

| 15 | 95 | 66.5 | 140 |

| 20 | 115 | 82.5 | 152 |

| 25 | 125 | 89 | 165 |

| 40 | 155 | 114.5 | 190 |

| 50 | 165 | 127 | 216 |

| 65 | 190 | 149 | 241 |

| 80 | 210 | 168.5 | 283 |

| 100 | 255 | 200 | 305 |

| 150 | 320 | 270 | 403 |

| 200 | 380 | 330 | 419 |

| 250 | 445 | 387.5 | 457 |

| 300 | 520 | 451 | 502 |

All dimensions are in mm.

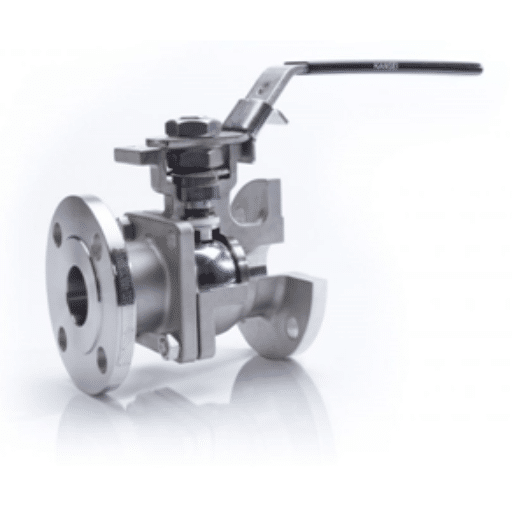

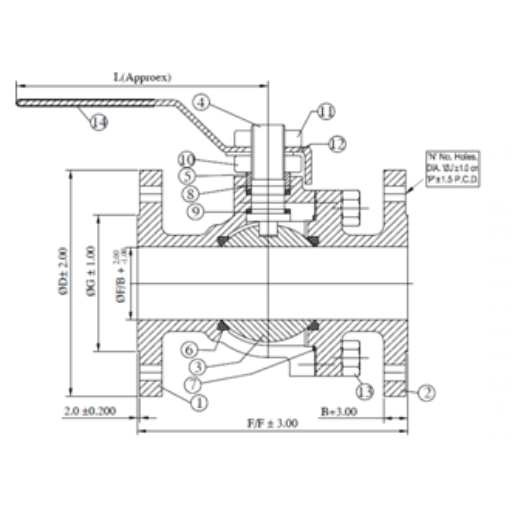

Ball Valves Two Piece, Full Bore, Flange end (150#, 300#)

Technical Data :

| Design Std. | As per ISO 17292 & BS 5351 |

| End Connection | Flanged End |

| Testing Std. | As per API 598 or ISO 5208 |

| Size 150# & 300# | 15 mm to 300 mm (1/2" to 12") |

BILL OF MATERIALS

| Sr. No. | Description | Material |

| 1 | Body | CI / WCB / CF8 / CF8M |

| 2 | Adaptor | CI / WCB / CF8 / CF8M |

| 3 | Ball | CF8 / CF8M |

| 4 | Stem | SS304 / SS316 |

| 5 | Gland | SS304 / SS316 |

| 6 | Seat Ring | PTFE / GFT / CFT |

| 7 | Body Seal | PTFE / GFT / CFT |

| 8 | Gland Packing | PTFE / GFT / CFT |

| 9 | Stem Seal | PTFE / GFT / CFT |

| 10 | Gland Nut | MS / SS304 |

| 11 | Lever Nut | MS / SS304 |

| 12 | Lever | MS / SS |

| 13 | Stud | MS / SS304 |

| 14 | Stud Nut | MS/SS304 |

| 15 | Stud Washer | MS/SS304 |

| 16 | Lever Sleeve | PVC |

DIMENSIONS 150#

| Size | Dia D | PCD | F/F |

| 15 | 90 | 60.5 | 108 |

| 20 | 100 | 70 | 117 |

| 25 | 110 | 79.5 | 127 |

| 40 | 125 | 98.5 | 165 |

| 50 | 150 | 120.5 | 178 |

| 65 | 180 | 139.5 | 191 |

| 80 | 190 | 152.5 | 203 |

| 100 | 230 | 190.5 | 229 |

| 150 | 280 | 241.5 | 267 |

| 200 | 345 | 298.5 | 292 |

| 250 | 405 | 362 | 330 |

| 300 | 485 | 432 | 356 |

DIMENSIONS 300#

| Size | Dia D | PCD | F/F |

| 15 | 95 | 66.5 | 140 |

| 20 | 115 | 82.5 | 152 |

| 25 | 125 | 89 | 165 |

| 40 | 155 | 114.5 | 190 |

| 50 | 165 | 127 | 216 |

| 65 | 190 | 149 | 241 |

| 80 | 210 | 168.5 | 283 |

| 100 | 255 | 200 | 305 |

| 150 | 320 | 270 | 403 |

| 200 | 380 | 330 | 419 |

| 250 | 445 | 387.5 | 457 |

| 300 | 520 | 451 | 502 |

All dimensions are in mm.

Ball Valves Two Piece, Metal Seated (150#, 300#)

Description

Kansei product KMS (Two-piece metal seated ball valve) in metal seated design as an additional option to our soft seated full port flanged series. This option increases the temperature rating to 750°F (399°C) and enhances wear resistance, while maintaining the proven safety and reliability of existing valves.Technical Data :

- Size Range: DN 15 (1/2”) – DN 200 (8”)

- Pressure: ASME Class 150 & 300

- Temperature range: Up to 400 deg. C

- Seat : SS 304 / SS316

- End Connections : Flanged ASME B16.5

- With ISO PAD

| Design Std. | As per ISO 17292 & BS 5351 |

| End Connection | Flanged End |

| Testing Std. | As per API 598 or ISO 5208 |

| Size 150# & 300# | 15 mm to 300 mm (1/2" to 12") |

MATERIALS (MOC)

| Sr. No. | Description | Material |

| 1 | Body | CI /WCB / CF8 / CF8M |

| 2 | Cap | CI / WCB / CF8 / CF8M |

| 3 | Ball | CF8 / CF8M |

| 4 | Stem | SS304 / SS316 |

| 5 | Gland | SS304 / SS316 |

| 6 | Seat Ring | SS304 / SS316 |

| 7 | Body Seal | PTFE / GFT / CFT |

| 8 | Gland Packing | PTFE / GFT / CFT |

| 9 | Stem Seal | PTFE / GFT / CFT |

| 10 | Gland Nut | MS / SS304 |

| 11 | Lever Nut | MS / SS304 |

| 12 | Lever | MS / SS |

| 13 | Stud & Nut | Ms / SS304 |

| 14 | Lever Sleeve | PVC |

| 15 | End Cap | PVC |

DIMENSIONS 150#

| Size | Dia D | PCD | F/F |

| 15 | 90 | 60.5 | 108 |

| 20 | 100 | 70 | 117 |

| 25 | 110 | 79.5 | 127 |

| 40 | 125 | 98.5 | 165 |

| 50 | 150 | 120.5 | 178 |

| 65 | 180 | 139.5 | 191 |

| 80 | 190 | 152.5 | 203 |

| 100 | 230 | 190.5 | 229 |

| 150 | 280 | 241.5 | 267 |

| 200 | 345 | 298.5 | 292 |

| 250 | 405 | 362 | 330 |

| 300 | 485 | 432 | 356 |

DIMENSIONS 300#

| Size | Dia D | PCD | F/F |

| 15 | 95 | 66.5 | 140 |

| 20 | 115 | 82.5 | 152 |

| 25 | 125 | 89 | 165 |

| 40 | 155 | 114.5 | 190 |

| 50 | 165 | 127 | 216 |

| 65 | 190 | 149 | 241 |

| 80 | 210 | 168.5 | 283 |

| 100 | 255 | 200 | 305 |

| 150 | 320 | 270 | 403 |

| 200 | 380 | 330 | 419 |

| 250 | 445 | 387.5 | 457 |

| 300 | 520 | 451 | 502 |

All dimensions are in mm.

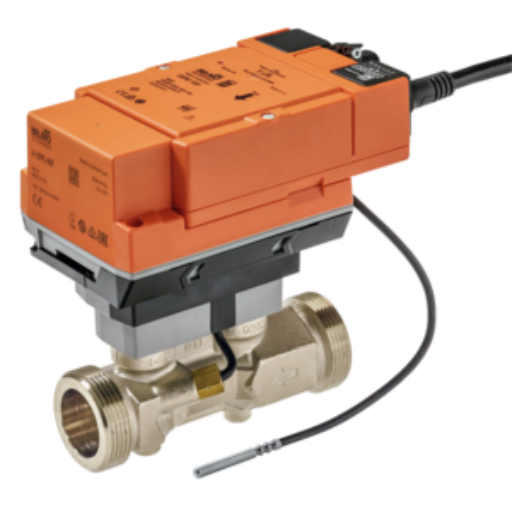

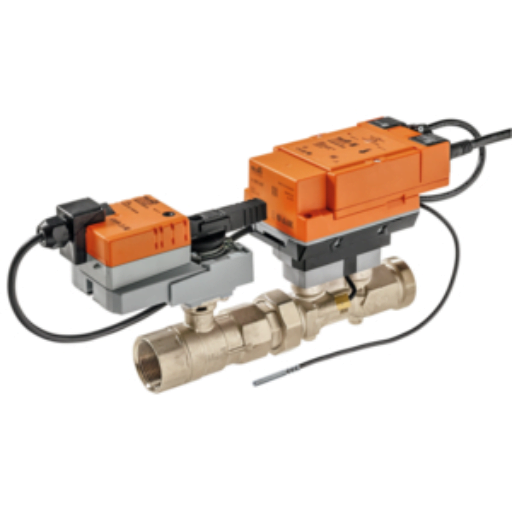

Belimo Ball Valves

Applications

The ball valve offers high close-off or change-over capabilities without leakage - that's efficiency.Achieve Control and Reliability

The R2, R3 and R6 series ball valves are available with non-spring return, spring return or electronic fail-safe actuators offering high close-off capabilities. The industrial ball valve series is a great solution for low and medium pressure steam applications up to 1000 kPa closed off pressure and applications that operate with a media temperature to 120º C.

High Performance for Aggressive Applications

Belimo industrial ball valves feature 2-way and 3-way configurations operated by rotary actuators. The actuators are controlled by a standard voltage for on/off, modulating, or floating point control which moves the valve to the position dictated by the control system. The series are Leakage rate A, air bubble tight preventing energy loss, which reduces operating costs.

Specification

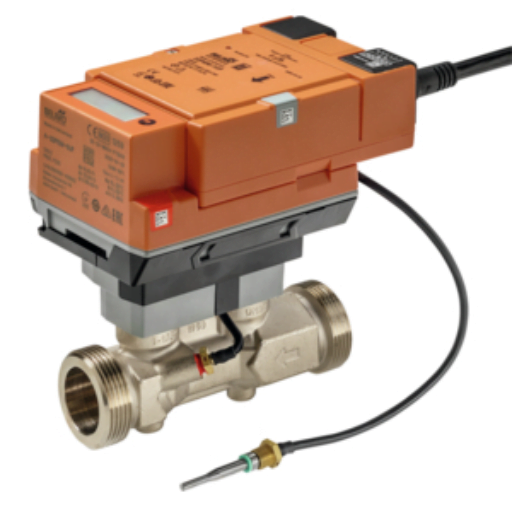

Pattern: 2-way, 3-way kvs range (kvs): 1.1...3.0 kvs, 3.1...6.5 kvs, 6.6...14 kvs, 15...40 kvs, 41...170 kvs, 171...1000 kvs Valve size (mm): 15 mm, 20 mm, 25 mm, 32 mm, 40 mm, 50 mm, 65 mm, 80 mm, 100 mm, 125 mm, 150 mm Pipe connection: Flange, Internal threadBelimo BTU Meter / Thermal Energy Meters (TEM)

Applications

Belimo thermal energy meters meet the requirements of EN1434 and have type approval according to MID 2014/32/EU. Types without approval are equipped with glycol compensation, who reliably measure the energy even if there is glycol in the water.Energy billing made easier than ever

Belimo's certified Thermal Energy Meters meet the requirements of EN 1434 and have type approval in accordance with the European Measuring Instruments Directive 2014/32/EU (MID). They provide validated data for invoicing purposes, which can be used for direct tenant billing. Our Thermal Energy Meters are also available as variant without MID / EN 1434 approval. They can reliably measure energy, even when there is glycol in the water. They automatically and continuously measure the glycol content in the fluid, compensate for it and, in doing so, ensure reliable ultrasonic volumetric flow measurement. This results in precise determination of the thermal energy. Belimo Thermal Energy Meters™ are designed to be multi-application devices, i.e. they can be used as heat application, cold application, or combined heat/cold application. They can also be installed either in the return pipe or in the supply pipe of the system. The application and installation position are provided to the valve during setup using a smartphone and the Belimo Assistant App or using a laptop and the built in web-server.

High-quality measurement

Multipoint wet calibration of the thermal energy meters

The new Thermal Energy Meters integrate energy metering and IoT-enabled billing in one device. They offer seamless and direct integration to the BMS or to IoT-based monitoring platforms, with IoT-based monitoring, performance improvement tools, and billing data. Bringing together performance features to save you time and money.

Specification

Certification: MID / EN 1434, Measured values, Temperature, Flow Flow range (m³/h): 0.015...1.5 m³/h, 0.025...2.5 m³/h, 0.035...3.5 m³/h, 0.06...6 m³/h, 0.1...10 m³/h, 0.15...15 m³/h Pipe size (mm): 15 mm, 20 mm, 25 mm, 32 mm, 40 mm, 50 mm Display type: LCDBelimo Butterfly Valves

Applications

The Butterfly valve series is available as Wafer- and Lug-Type in DN 25 - DN 700. It meets the requirements of all HVAC applications requiring zero leakage for 2-way and 3-way applications.The most intelligent butterfly valve on the market

Butterfly valve assemblies are available in sizes from 50 to 1200mm for 2-way application designed for piping systems requiring zero leakage. The assemblies are available with IP54 or IP66/ 67 housing and offer a range of Kvs values to provide an economic control valve solution for large high flow applications.

Game-changing butterfly control valves from DN 100 to DN 150

Say goodbye to high energy consumption, inefficiency, discomfort, and sky-high costs caused by outdated valves. We've revolutionized the industry by rendering these problems, along with the hassle of finding compatible retrofit solutions, a thing of the past. Thanks to our new butterfly control valves, ranging from DN 100 to DN 150, all these challenges have been solved for you. Join us on the journey towards sustainable and cost-effective HVAC solutions.

Learn more about our new control butterfly valves at the product launch event:

Key benefits of butterfly control valves from Belimo

The Belimo butterfly control valves are a smart, energy-efficient, and reliable solution for high-flow applications in the HVAC industry. They are perfectly suited for heating, chiller, and cooling tower applications, changeover systems, control applications for large ventilation systems, and bypass applications. The benefits of these new products include:

- JR and PR Actuator with high-performance chip allows smooth and efficient operation and ensures that the butterfly control valve operates with high precision

- Tight shut off leads to energy savings in HVAC applications as well as money savings

- Simple installation, commissioning, and maintenance with the Belimo Assistant App

- Access to diagnostic options via the App

- Application parameters option such as linear or equal percentage control characteristic is available, communication protocol is also available for BACnet MS/TP, Modbus RTU and Belimo MP-BUS

- Up to two temperature sensors can be connected to create an optimised system

- The product stands out for its quality, flexibility, reliability and durability

8 reasons for using Belimo butterfly valves

1. Flexible utilisation options

2. Absolute seal integrity

3. Energy-saving design

4. Reduced weight and low installation height

5. Transparent communication

6. Seamless integration of sensors

7. High operating safety

8. Fit for reliable control tasks

Only the best is good enough

Our commitment to continuous improvement remains unwavering as we methodically enhance our products on the basis of the latest research, the expertise of experienced engineers and customer feedback. Innovation lies at the heart of our quality guarantee, driving us to create products that meet and surpass our customers' expectations. This was also the case when we developed the butterfly control valve range from DN 100 to DN 300 together with the JR and PR actuator.

The new butterfly control valves are designed with the highest quality materials to ensure durability and reliability. In over one million test cycles, we have thoroughly tested the products under real-life conditions and in our laboratories. Robustness, reliability, and water resistance, among other things, have been successfully tested, and third parties conducted all relevant certification tests. A 5-year warranty backs Belimo products.

Belimo butterfly control valve at a glance

- Our successful product range has been further enhanced with the launch of the butterfly control valves from DN 100 to DN 150. This addition allows us to cover a wide range of applications, up to DN 300. More to come soon up to DN 450.

- Also, don't forget to check out our full range of current butterfly valves, reaching from the small size of DN 25 up to the enormous size of DN 1200.

Specification

Valve size (mm): 25 mm, 32 mm, 40 mm, 50 mm, 65 mm, 80 mm, 100 mm, 125 mm, 150 mm, 200 mm, 250 mm, 300 mm, 350 mm, 400 mm, 450 mm, 500 mm, 600 mm, 700 mm, 800 mm, 900 mm, 1000 mm, 1200 mm kvs range (kvs): 15...40 kvs, 41...170 kvs, 171...1000 kvs, 1001...10000 kvs, 10001...42800 kvs, > 42800 kvs Kvmax range: 41...170 Kvmax, 171...1000 Kvmax, 1001...10000 Kvmax, 10001...42800 Kvmax End connection: Lug types, Wafer types Close-off pressure: 1000 kPa,1200 kPa, 2200 kPa PN: 6 / 10 / 16 PN , 10 / 16 PN , 16 PN , 25 PNBelimo Characterised Control Valves (CCV)

Applications

The Characterised Control Valve (CCV) combines the high close-off capabilities of a ball valve with true equal percentage flow characteristic to achieve superior control.Control and Reliability

The Characterised Control Valve (CCV) marks a true advancement in control valves. It combines the high close-off capabilities of a ball valve with a specialised disc that ensures an equal percentage flow characteristic. Since its release in 1999, over 2 million CCVs have been sold in hydronic systems. The CCV offers a comprehensive Kvs range for various applications such as air handlers, heating and cooling coils, fan coil units, unit ventilators and VAV re-heat coils.

True Advancement in Control Valves

Belimo Characterised Control Valves feature the innovative ball design and are operated by a rotary actuator. The actuators are controlled by a standard voltage for on/off, modulating, or floating point control which moves the ball valve to the position dictated by the control system. The valve is bubble-tight preventing energy losses and helps reduce operating costs.

Specification

Pattern: 2-way, 3-way kvs range (kvs): 0.25...1.0 kvs, 1.1...3.0 kvs, 3.1...6.5 kvs, 6.6...14 kvs, 15...40 kvs, 41...170 kvs, 171...1000 kvs Valve size (mm): 15 mm, 20 mm, 25 mm, 32 mm, 40 mm, 50 mm, 65 mm, 80 mm, 100 mm, 125 mm, 150 mm Pipe connection: Flange, Internal threadBelimo Duct Sensors (T/RH)

Applications

Belimo offers a wide range of air duct sensors covering all standard measurement values: temperature, humidity, dew point, CO₂, VOC’s, pressure and frost detection.Providing the Reliability, You Know and Expect

Belimo offers a line of duct sensors covering measurement values for temperature, humidity, enthalpy, dew point, CO₂, VOC’s, pressure, and low temperature limit detection backed with UL certification and a 5-year warranty.

Accurate Reading

Belimo duct sensors offer a snap-on NEMA 4X, IP 65 enclosure for easy installation and commissioning, field selectable ranges, high accuracy and reliability, self-calibration features, and mounted accessories are included.

Specification

Measured values: Temperature, Frost, Safety temperature, Humidity, Condensation, CO₂, VOC, Differential pressure, Volumetric flow Output signal: 0...5 V, 0...10 V, 4...20 mA, Switch, Modbus, BACnet, Pt100, Pt1000, Ni1000, Ni1000TK5000, NTC10k (10k2), NTC10k Pre (10k3), NTC10k Carel, NTC20k Measuring range temperature (°C): -50...150 °C, -50...160 °C, -50...250 °C, -40...80 °C, -35...70 °C, -35...100 °C, -10...15 °C, 0...15 °C, 0...50 °C, 30...90 °C, 50...80 °C, 70...130 °C Measuring range pressure (Pa): -150...250 Pa, -100...2500 Pa, 0...7000 Pa, 20...300 Pa, 50...500 Pa, 200...1000 Pa, 500...2500 Pa, 1000...5000 Pa Mounting type: Average, Single point, Immersion Probe length: 50 mm, 100 mm, 140 mm, 150 mm, 156 mm, 180 mm, 200 mm, 270 mm, 300 mm, 450 mm, 3 m, 6 m Additional features: Manual reset, Auto reset, Auto or manual reset, Internal sensor, External sensor, Auto-Zero, 2 measuring systems Display type: LCD, LEDBelimo Electronic Pressure Independent Valves (EPIV)

Applications

Belimo's pressure independent valve technology optimises the control of variable flow systems and helps maximise energy savings.High Performance Solutions

Belimo pressure independent valve technology maximises energy savings of variable flow pumping systems while addressing unique control challenges. Belimo offers a series of pressure independent (PI) control valves; from the PIQCV, a super compact PI valve, ePIV an electronic PI valve offering true flow measurement to the Energy Valve that optimises, documents and proves water coil performance.

Energy Efficient Valves Providing Optimal Performance

With Belimo’s pressure independent control valve technology only a single valve is required to maintain proper flow through each circuit. Each valve arrives from the factory pre-set for each circuit and can be changed in the field, so there is no additional balancing required. The system performs perfectly from start-up. Pressure independent valves are used to regulate flow through air handlers, heating and cooling coils, fan coil units, unit ventilators and VAV re-heat coils.

Specification

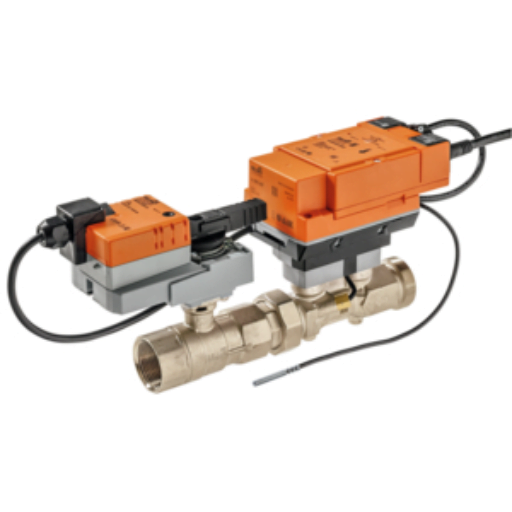

Product type: Valve, Valve-actuator unit PI-Technology: Electronic, Mechanical Pipe connection: Flange, Internal and external thread, Internal thread Valve size (mm): 15 mm, 20 mm, 25 mm, 32 mm, 40 mm, 50 mm, 65 mm, 80 mm, 100 mm, 125 mm, 150 mm Fail-safe function: Non-fail-safe, Fail-safe Voltage AC/DC: 24 V Control type: Modulating, Communicative, Hybrid (communicative / analogue) Running time (fail-safe): 35 s Electrical connection: CableBelimo Energy Valve™

Applications

The Belimo Energy Valve™ is a pressure independent control valve that in addition monitors coil performance and energy consumption. On request, it can also manage the Delta T and communicates with the IoT cloud.Energy savings you can see

The Belimo Energy Valve™ provides pressure-independent flow control and transparent monitoring of heating or chilling systems. This ensures that it is not operated with too low a temperature spread (delta T). By measuring, calculating and visualising important system data and with the performance reports provided by Belimo, energy-efficient system operation is guaranteed for the entire service life. The Belimo Energy Valve™ can be connected to the Belimo Cloud, providing easy access to data and reports – anytime, anywhere.

Thermal energy management and billing made easier than ever

The unity of the certified Belimo Thermal Energy Meter™ and the enhanced Belimo Energy Valve™ allows for transparent thermal energy management. The two worlds of "energy control" and "certified energy measurement and billing" are now being united. Accurately measure and monitor thermal flows and energy consumption in heating and cooling systems with direct IoT-based cost accounting using a single device. The new MID-approved Thermal Energy Meters assure high accuracy and reliability, allowing for easy and efficient billing. Reliable measurement is only the beginning. The Belimo Energy Valve™ instantly controls the thermal flow and optimises the energy supply to the user. With this important combination Belimo is stepping into a new era of integrated thermal energy management and is bringing together what belongs together.

Belimo Energy Valve™ in HVAC Applications

This is a selection of common HVAC applications in which the Belimo Energy Valve™ comes into use. After a short description of each application, common reasons for poor efficiency or performance are identified. There is an explanation of how the EV addresses these problems, and which control modes and settings are recommended to achieve optimal performance.

Know where the energy is going

The Belimo Energy Valve™ is an IoT device, i.e. an intelligent pressure-independent valve that can be connected to the Belimo Cloud. Unique functions such as the Delta-T manager or the possibility of direct power control provide clarity, enhance efficiency and reduce costs. The Belimo Energy Valve™ consists of a 2-way or 3-way characterised control valve, a volumetric flow meter, two temperature sensors and an actuator with integrated logic.

Pipe connection: Flange, Internal and external thread

Certification: MID / EN 1434

Flow range (m³/h): 0.02...2.39 m³/h, 2.4...6.49 m³/h, 6.5...17.5 m³/h, 17.6...40 m³/h, 41...162 m³/h

Valve size (mm): 15 mm, 20 mm, 25 mm, 32 mm, 40 mm, 50 mm, 65 mm, 80 mm, 100 mm, 125 mm, 150 mm

Fail-safe function: Non-fail-safe, Fail-safe

Specification

Belimo Fail-Safe Damper Actuators

Applications

Belimo rotary actuators with fail-safe can handle a magnitude of HVAC applications. They are available in a wide range of nominal voltages and torques.Reliability and Safety Performance

Belimo fail-safe damper actuators have a comprehensive torque offering from 2.5 Nm to 40 Nm with direct coupled, rotary or linear travel that can handle many HVAC applications. Fail-safe actuators use brushless DC motor technology controlled by an Application Specific Integrated Circuit (ASIC) to provide stall protection, lower power consumption, higher efficiency and smaller transformer sizing.

Powerful and Reliable Control

Fail-safe actuators provide lower power consumption, increase torque and faster running times with MFT technology. Belimo actuator accessories increase application flexibility with more options in mounting and commissioning. A wide selection of universal clamps, electrical connections and running times are now available, providing you a cost effective solution with the same reliability you have come to experience with Belimo.

Specification

Torque: 1 Nm, 2 Nm, 4 Nm, 5 Nm, 8 Nm, 10 Nm, 16 Nm, 20 Nm, 40 Nm, 160 Nm Force: 50 N, 100 N, 150 N Voltage AC/DC: 120 V, 230 V, 24 V, 48 V, 72 V Control type: Open/close, 3-point, Modulating, Communicative, Hybrid (communicative / analogue) Running time: 2.5...19 s, 20...49 s, 50...79 s, 80...99 s, 100...150 s Mechanical interface: Form fit, Universal shaft clamp, Universal shaft clamp reversible Auxiliary switches: 1x SPDT, 2x SPDT Electrical connection: Cable, Connector plug, Terminals Protection category: IP20, IP54, IP66/67Belimo Fire Damper Actuators

Applications

Specifically designed safety actuators for the motorisation of fire dampers provide best protection against the spread of fire and smoke through the air ducts.Technology that Saves Lives

Belimo fire and smoke damper actuators are designed for operation in smoke and combination fire and smoke dampers in ventilation and air-conditioning systems with a torque range from 2 Nm to 40 Nm @ 177°C. For maximum safety in all situations, the fire and smoke actuators meet all codes for commercial buildings in the U.S., pass UL 555 and UL 555S at 177ºC and are tested for 30,000 open-closed cycles with approved dampers. Belimo fire and smoke damper actuators exceed UL’s requirement of 20,000 cycles at damper static load.

Safety in Buildings

Belimo fire and smoke damper actuators have an extensive torque range specifically designed for operation with fire, smoke, and combination fire and smoke dampers in ventilation and air-conditioning systems. As an integral part of the life safety system, Belimo fire and smoke actuators provide high performance, low power consumption, and are compliant with Life Safety Codes and Standards.