Showing 37–48 of 131 results

Ball Valves One Piece Full, Bore Screw end (150#)

Technical Data :

| Design Std. | As per ISO 17292 & BS 5351 |

| End Connection | Screwed End |

| Testing & Std. | As per API 598 / ISO 5208 |

| Size, 150# | 15 mm to 50 mm (1/2" to 2") |

MATERIAL (MOC)

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Cap | WCB / CF8 / CF8M |

| 3 | Ball | CF8 / CF8M |

| 4 | Steam | SS304 / SS316 |

| 5 | Gland | SS304 / SS316 |

| 6 | Seat Ring | PTFE / GFT /CFT |

| 7 | Body Seal | PTFE / GFT /CFT |

| 8 | Gland Packing | PTFE / GFT /CFT |

| 9 | Gland Nut | MS/SS304 |

| 10 | Lever Nut | MS/SS304 |

| 11 | Lever | MS/SS |

Dimensions 150#

| Size | NB | F/F | Thread Type |

| 15 | 12.5 | 58.8 | BSP/NPT |

| 20 | 19.0 | 68.5 | BSP/NPT |

| 25 | 25.0 | 76.5 | BSP/NPT |

| 32 | 32.0 | 90.0 | BSP/NPT |

| 40 | 38.0 | 100.0 | BSP/NPT |

| 50 | 50.0 | 118.0 | BSP/NPT |

All Dimensions are in mm

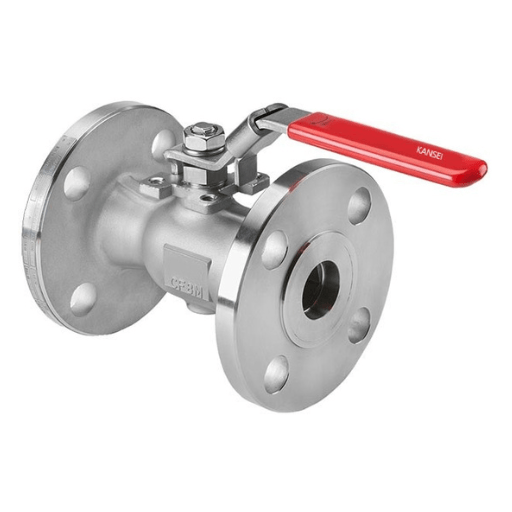

Ball Valves One piece, Fire safe-antistatic design, Reduced bore, Flange end (150#, 300#)

Description

One Piece design features eliminates any possible and potential leak paths. Inserts holds the internal assembly in position. This creates a positive metal to metal sealing between body and insert which eliminates the leakage through flange. Ideally suitable for use in oil and gas production, refining and chemical applications. Body material and wetted trim components confirms to NACE standard MR 0175. Fire safe and Anti-static design where Hazardous areas with handling of flammable fuels, gases or chemicals are in use.Technical Data :

- Size Range: DN 50(2") – 200(8")

- Pressure rating : ASME Class 150 to 300

- Temperature range : Upto 260 deg. C

- Seat : PTFE / Carbon Reinforced PTFE

- End Connections : Flanged ASME B16.5

- With & Without ISO PAD

- MOC : WCB, PTFE, CF8, 304 S/S, 316 S/S, MS, CF8M, SS, Carbon R'PTFE

Ball Valves One/Two Piece, Fire Safe-Antistatic design, Full bore Flange end (150#,300#)

Description

One Piece body from DN 15 to DN 40 and Two-piece design from DN 50 to DN 200 valve size. Ideally suitable for use in oil and gas production, refining and chemical applications. Body material and wetted trim components confirms to NACE standard MR 0175. Fire safe and Anti-static design where Hazardous areas with handling of flammable fuels, gases or chemicals are in use.Technical Data :

- Size Range: DN 15 – DN 40 (One piece), DN 50 – DN 200 (Two piece)

- Pressure rating: ASME Class 150 & 300

- Temperature range: Up to 260 deg. C

- Seat: PTFE / Carbon Reinforced PTFE

- End Connections: Flanged ASME B16.5

- With & Without ISO PAD

- MOC : WCB, PTFE, CF8, 304 S/S, 316 S/S, MS, CF8M, SS, Carbon R’PTFE

Ball Valves Three Piece Full bore with Locking device (PN40/PN63) Screw End, Socket Weld, Butt Weld

Description

Three Piece body from DN 15 to DN 100. Swing out economical design for Industrial & Process applications. Investment casting for body and end cap. End connections with Screwed end – Socket weld – Butt weld. Blow out proof stem design with LOTO Features for Lock out and Tag out arrangement.Technical Data :

- Size Range: DN 15(1/2”) – DN 100 (4”)

- Pressure rating: PN40 & PN63

- Temperature range: Up to 260 deg. C

- End Connections: Screwed End, Socket Weld, Butt Weld

- MOC : WCB, PTFE, CF8, 304 S/S, 316 S/S, MS, CF8M, SS, Carbon R’PTFE

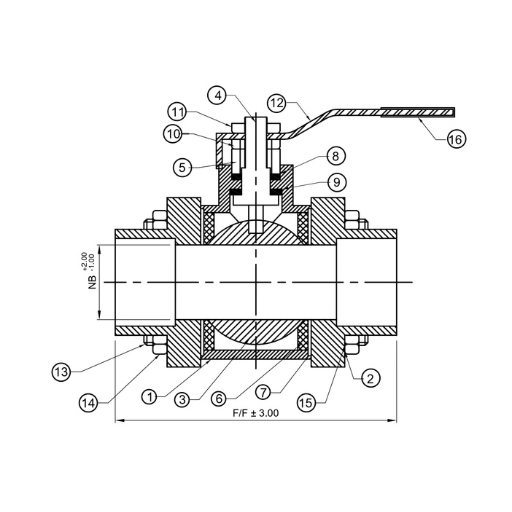

Ball Valves Three Piece, Full Bore (Screw End, Socket Weld) (150#, 300#, 600#, 800#)

Technical Data :

| Design Std. | As per ISO 17292 & BS 5351 |

| End Connection | Screwed End/Socket Weld |

| Testing & Std. | As per API 598 / ISO 5208 |

| Size, 150# | 15 mm to 50 mm (1/2" to 2") |

Material (MOC)

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Adaptor | WCB / CF8 / CF8M |

| 3 | Ball | CF8 / CF8M |

| 4 | Steam | SS304 / SS316 |

| 5 | Gland | SS304 / SS316 |

| 6 | Seat Ring | PTFE / GFT /CFT |

| 7 | Body Seal | PTFE / GFT /CFT |

| 8 | Gland Packing | PTFE / GFT /CFT |

| 9 | Steam Seal | PTFE / GFT /CFT |

| 10 | Gland Nut | MS/SS304 |

| 11 | Lever Nut | MS/SS304 |

| 12 | Lever | MS/SS |

| 13 | Stud | MS/SS304 |

| 14 | Stud Nut | MS/SS304 |

| 15 | Stud Washer | MS/SS304 |

| 16 | Lever Sleeve | PVC |

Dimensions 150#

| Size | NB | F/F | Thread Type |

| 15 | 12.5 | 62.5 | BSP/NPT/SW |

| 20 | 19.0 | 74.0 | BSP/NPT/SW |

| 25 | 25.0 | 87.0 | BSP/NPT/SW |

| 40 | 38.0 | 109.0 | BSP/NPT/SW |

| 50 | 50.0 | 110.0 | BSP/NPT/SW |

All Dimensions are in mm