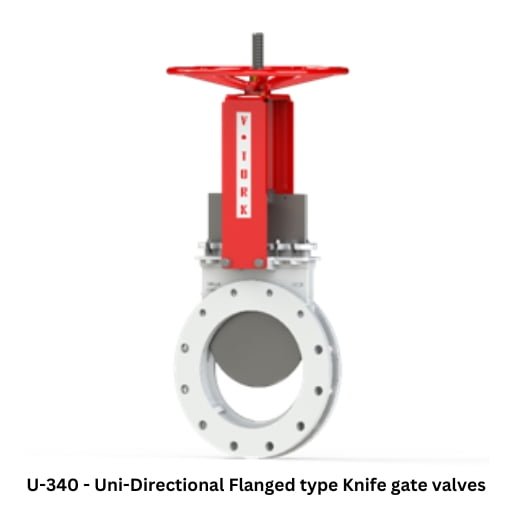

- Uni Directional, Wafer Type

- Size 2” to 120” (50mm to 3000mm)

- Metal Seated / Resilient Seated

- Single Piece Construction

- 150 PSI CWP

- Standard: MSS SP-81, MSS SP-148, MSS SP-151

Applications:

Liquid/Slurry Application: Abrasive Slurries in Mineral Industries, Pulp Slurry, Chemical Slurry, Molasses, Raw Water Intake, Ash Slurries in Thermal Power Plant, Chemical Slurries in Chemical Process Industries, Sugar Juice in Sugar Industries

Bulk Handling (Solids & Powders): Pneumatic Conveying systems, Detergent Powders/Cake, Boiler bed ash, Carbon Black, Coal handling, Lime powder handling applications.

Gas Application: Blast Furnace Gas in Steel industries, Pulverized coal fired lines in Thermal Power Plants, Hot gas handling.

Powder Applications: Lime powder, Silica/ Magnesium Oxide/ Calcium Oxide/ Al Oxide/ Zyconium Oxide.

Range of Material of Construction CI / DI / WCB / CF8 / CF8M / CF3M / CG8M / SMO254 / Duplex 2205 & Special Materials on Request

Range of Seat Materials EPDM / Viton / Natural Rubber / Nitrile/ PTFE/ Metal Seat

Range of Actuators Hand Wheel, Lever Operated, Chain Wheel, Bevel Gear, Pneumatic Double Acting/Single Acting Cylinder, Hydraulic Cylinder, Electro-Pneumatic Operation, Motorized

Range of Accessories Solenoid Valve, Limit Switch, Proximity Switch, Junction Box, Positioner, Accumulator for Emergency Shut Off, Wear Rings, AFR, Speed Control Valves

Range of Addl. Features Deflection cone, V-Orifice, Purge Port, Stem Extension, Fail Safe System, Locking Arrangement, Renewable seats, Non raising Stem arrangement.