Armstrong 4300 vertical in-line pumps

- Applications-HVAC-system pumping; light industrial/ process pumping (water or glycol based)

- Description-The Armstrong 4300 pipe-mounted pumps are designed for space-saving installation, high operating efficiency, and long service life

- Materials(MOC)-Cast, ductile iron or bronze casing, Cast iron or bronze impeller

- Configuration-Outside balanced or inside single spring mechanical seal

- Performance range-Up to 28,000 USgpm (1,800 L/s) Flow; up to 500 ft (150 m) Head

- Temperature-300oF (150oC)

- Power Range-1 hp to 1250 hp (0.75 kW to 900 kW)

- Size-1.5″ to 20” (40 mm to 500 mm)

Description

Benefits & Features

Low installed cost

- Vertical In-line design eliminates the need for inertia bases, housekeeping pads, flex connectors, and field alignment or grouting requirements.

- Vertical In-line design minimizes space and pipe requirements.

- Isolated mechanical seal design with optional sediment filters or separators available to extend seal life in contaminated systems.

Low energy consumption and operating cost

- Armstrong 4300 pumps are available with high-efficiency NEMA-premium motors for significant reduction in energy consumption and cost.

- All motors are suitable for inverter-fed service.

- Vertical In-line design minimizes pipe requirements and related friction losses resulting in higher system efficiency.

- Split-coupling allows replacement of mechanical seal without disturbing the pump or motor.

- No lubrication or seal adjustments required.

Low operating risk

- Universal replacement seals, bearings, and motors available locally world-wide.

- Optional isolated mechanical seal with sediment filters or separators for extended seal life in contaminated systems.

- Vertical In-Line configuration allows for less disruptive pump service. (casing stays in place)

Related products

Armstrong 4280 Motor Mounted Pumps

- Applications-HVAC-system pumping; light industrial / process pumping.

- Description-The Armstrong 4280 horizontal end-suction pumps are equipped with close-coupled motors to minimize footprint requirements.

- Materials(MOC)-Cast iron, ductile iron, or bronze casing, Cast iron or bronze impeller.

- Configuration-Inside single-spring mechanical seal

- Performance range-Up to 2,000 USgpm (125 L/s) flow; up to 400 f (120 m)

- Temperature-250°F (121°C)

- Power Range-0.33 hp to 60 hp (0.25 kW to 45 kW)

- Size-1" to 6” (25 mm to 150 mm)

Armstrong Design Envelope 4300 Pumps

- Applications-HVAC-system pumping and control; general purpose pumping; industrial/process pumping and control. (water or glycol based)

- Description-Pipe-mounted UL 778 pumping unit with integrated intelligent controls for space-saving installation and superior energy performance. Saves up to 75% in energy over comparable traditional constant speed or variable frequency operated pump installations. Remote services through internet to enhance reliability and sustain optimal performance over life of pumps.

- Materials(MOC)-Ductile iron e-coated casing, Stainless steel impeller, Sintered silicon carbide mechanical seal

- Configuration-On-board Intelligent Variable Speed controls with Sensorless control. Split-coupling design and outside balanced or inside single spring mechanical seal. Controls enclosure UL type 12 or UL type 4X for outdoor applications. 0.33-50hp range standard with DEPM motors that reduce losses by more than 20% over NEMA Premium efficiency. Network capable for remote performance management services.

- Performance range-25 to 25,000 USgpm (1.5 to 1500 L/s) flow; 10 to 300 ft (3 to 90 m) head (composite curves available)

- Temperature-300oF (150oC)

- Power Range-0.33 hp to 1250 hp (0.25 kW to 900 kW)

- Size-1″ to 20″ (25 mm to 500 mm)

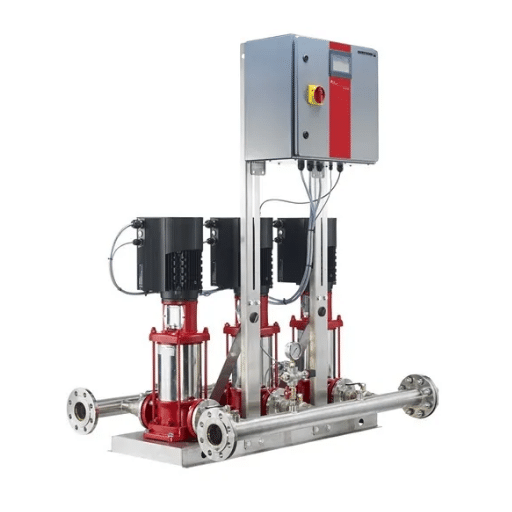

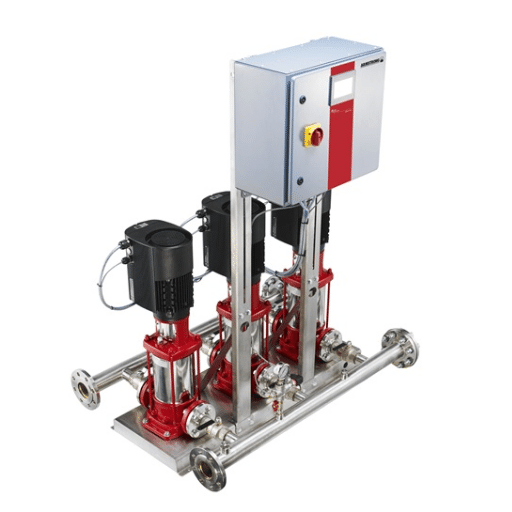

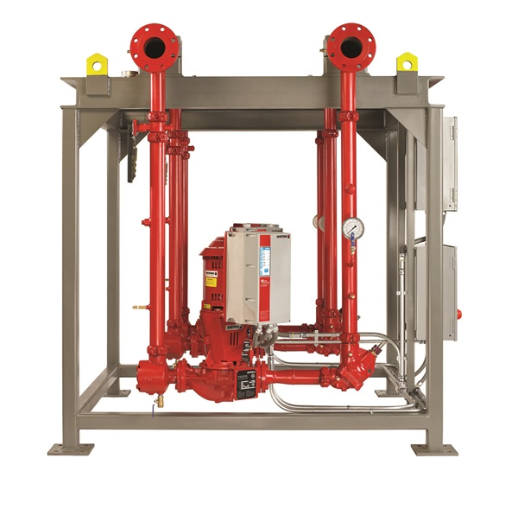

Armstrong Design Envelope 6800 Vertical Multistage Boosters

- Applications-New and retrofit water boosting installations in mid to large size residential, commercial, or industrial settings (such as apartment buildings, office towers, hospitals, hotels, schools, water treatment plants, factories, etc.)

- Description-The Armstrong Design Envelope 6800 Boosters are fully assembled, programmed, integrated and factory-tested turn-key booster systems. They are equipped with vertical multistage pumps and come in arrangements of 2 to 5 pumps. The integrated controls allow for superior performance and energy efficiency across broad operating envelopes. Most suitable for applications where energy consumption and low maintenance are critical, installation space comes at a premium, and occupant comfort is a high priority.

- Materials (MOC)-Piping: stainless steel 304

- Configuration-The 6800 Booster range offers enhanced features, such as improved touchscreens, more performance envelopes, an easy-to-use selection software, and onboard energy and flow readings both present and historic. For the full improved feature set please refer to the Solution Outline for this product.

- Performance range-Up to 2000 USgpm (450 m3/hr) flow; up to 370 psi (22 bar) pressure

- Power Range-Up to 250 hp (up to 185 kW)

Armstrong Design Envelope 9521 Integrated Plant Control System (IPC 9521)

- Applications-Automated chiller plant control for optimizing variable primary flow water-cooled chiller plants. The 9521 IPC works in a variable primary configuration and keeps the entire plant including water-cooled chillers, cooling towers, chilled water and condenser pumps running smoothly.

- Description-The Armstrong Integrated Water-Cooled Chiller Plant Control System (IPC) boosts energy efficiencies of new and existing chiller plant installations to leading class levels. The IPC 9521 works with all variable primary configurations, keeping the entire plant – including water-cooled chillers, cooling towers, chilled water and condenser pumps – running at optimum performance and occupant comfort.

- Configuration-Integrates with all brands of chillers, pumps, and automation systems. Installs directly with chiller plant equipment. If preferred, the IPC connects seamlessly with any central building automation system (BAS) maintaining full control of the chilled water plant through the BAS

- Performance range-Controls up to five chillers, five cooling towers and five pumps. No limitations in plant size and cooling capacity.

- Power Range-No limitations in plant cooling capacity

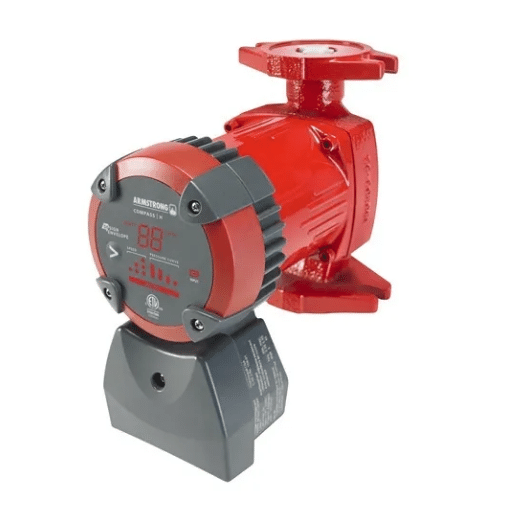

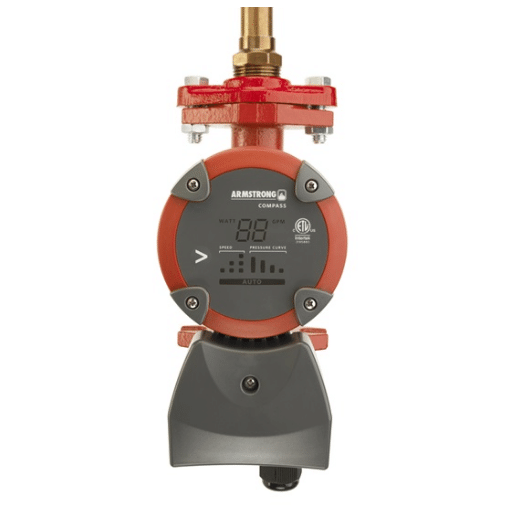

Armstrong Design Envelope Compass h Circulators

- Applications-Residential heating and cooling; potable water supply.

- Description-The Armstrong Compass H is an energy-efficient variable speed wet-rotor circulator. Designed to replace existing fixed speed circulators, with popular flange-to-flange dimensions, Compass H can be considered a universal replacement for all circulators in its capacity range.

- Materials (MOC)-Cast iron and stainless steel volutes.

- Configuration-Eight operation modes with patented “Auto” algorithm, four Sensorless modes and three fixed speed modes. 50 Hz and 60 Hz designs

- Performance range-Up to 20 USgpm (1.26 L/s) flow; up to 20 ft (6.1 m) head

- Temperature-Max ambient temp. 40°C; max water temp. 110°C

- Power Range-5 W to 45 W

- Size-1″

Armstrong Design Envelope Integrated Pumping System (IPS 4000)

- Applications-Multi-pump control for heated – or chilled – water system optimization in buildings.

- Description-The Design Envelope Integrated Pumping System (IPS 4000) is an advanced multi-zone control that directly integrates with pumping units to optimize energy performance, system handling, and installation.

- Materials (MOC)-Enclosure, circuitry, software

- Configuration-Integrates seamlessly with Armstrong Design Envelope pumps in a headered configuration.

- Performance range-Up to 8 pumps, 16 zones (variable primary, secondary or tertiary) and 8 flow sensitive equipment (variable primary) IPS 4001w / IPS 4501w for up to 3 pumps, 3 zones and 3 flow sensitive equipment IPS 4002w / IPS 4502w for up to 4 pumps, 6 zones and 4 flow sensitive equipment IPS 4003w / IPS 4503w for up to 6 pumps, 12 zones and 6 flow sensitive equipment IPS 4004w / IPS 4504w for up to 8 pumps, 16 zones and 8 flow sensitive equipment

- Power Range-No limitations in system size and capacity.

- Size-No limitations in system size.

Armstrong Design Envelope Intelligent Fluid Management System

- Applications-Commercial or industrial closed-loop systems, including HVAC chilled-water systems, boiler systems, cooling tower systems, or process water loops.

- Description-The Armstrong Intelligent Fluid Management System (iFMS) integrates superior pump- and control technology into a single pumping solution yielding both compact and carefree installation as well as superior energy performance. iFMS is ideally suited for partial or all variable speed chilled-water plant applications (variable primary flow, variable secondary flow, variable condenser water flow). In combination with Parallel Sensorless control iFMS saves 30% or more in energy over any other parallel pumping configuration available today.

- Configuration-Up to 4 pumps in one unit. Catalogue-based pre-engineered solutions or designed to customer specification. Integrated control system (IPS 4000, IPC 11550) or connecting to chiller plant/BMS control. Optional single point power panel

Armstrong Suction Guides

- Applications-HVAC-system pumping; general purpose pumping; industrial/process pumping (water or glycol based).

- Description-The Armstrong Suction Guides (SG) are multi-function pump fittings that provide a 90° elbow, guide vanes, and an in-line strainer. Suction guides reduce pump installation cost and floor space requirements.

- Materials (MOC)-Cast Iron, ductile iron; grooved, flanged or threaded connections

- Performance range-Suitable for all Armstrong commercial pumps and pumping systems

- Temperature-230°F (110°C)

- Size-1.5” to 20” (40 mm to 500 mm)