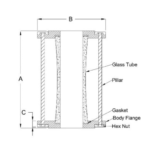

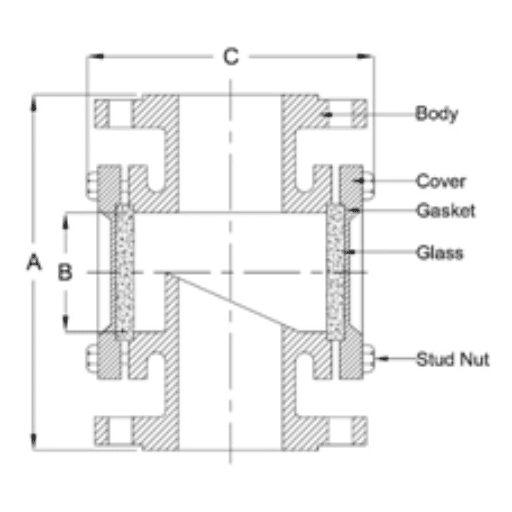

Full View Sight Glass (PN10)

Applications:

Industrial facilities, oil refineries, bath soap manufacturing plane, gas industries, petrochemical complex, high viscous process media, building construction, environmental water treatments, synthetics, plastic and resin industries, polymer manufacturing plant, food industries (chocolate, sauce etc.), fertilizer industries etc.

Technical Data :

| Design Std. | As per BS 5352 |

| Testing Std. | As per API 598 |

| End Connection | As per ANSI B16.5 |

| Size | ½” to 4” (15 mm to100 mm) |

| Pressure rating | PN10 |

| Maximum working pressure | 10 Kg/cm2 |

| Test pressure | 15 Kg/cm2 |

Dimensions

| Size | A | B | C |

| 15 | 153 | 51 | 137 |

| 20 | 153 | 51 | 137 |

| 25 | 153 | 51 | 137 |

| 40 | 178 | 64 | 146 |

| 50 | 190 | 76 | 190 |

| 75 | 229 | 102 | 132 |

| 100 | 299 | 127 | 283 |

All dimensions are in mm.

Description

General Notes :

- Customization and Automation as per customer requirements.

- Certificate of compliance to EN10204 Type 3.1 as standard.

- Safety stock as per customer requirements.

- 100% factory tested and inspected valves as per standard.

- Other trims also available as per customer requirements.

- Support to customers for other product requirements from sources.

- Consult to Factory for Torque and Other Details.

Related products

Armstrong Expansion Tanks

- Applications-Pressure stabilization in water based mechanical systems such as booster installations, boiler systems, and chiller plants

- Description-Armstrong Expansion Tanks are designed to reduce tank sizes by up to 80% over standard designs. Expansion tanks use compressed air to maintain system pressures by accepting and expelling the changing volume of water as it heats and cools. Diaphragm or bladder tank designs isolate the expanded water from the pressure controlling air cushion – which is pre-charged at the factory and can be adjusted in the field to meet final system requirements

- Materials (MOC)-Carbon steel (shell), heavy duty Butyl (diaphragm)

- Performance range-AET plain steel expansion tanks: 15 to 525 USgpm flow. AX diaphragm expansion tanks: 8 to 211 USgpm flow. Type L bladder type expansion tanks: 10 to 1056 USgpm flow.

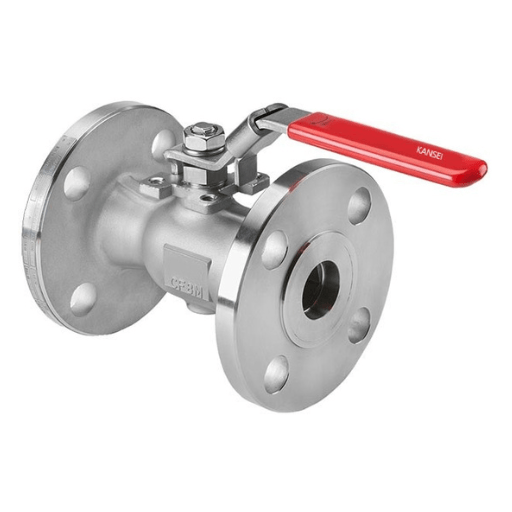

Ball Valves One piece, Fire safe-antistatic design, Reduced bore, Flange end (150#, 300#)

Description

One Piece design features eliminates any possible and potential leak paths. Inserts holds the internal assembly in position. This creates a positive metal to metal sealing between body and insert which eliminates the leakage through flange. Ideally suitable for use in oil and gas production, refining and chemical applications. Body material and wetted trim components confirms to NACE standard MR 0175. Fire safe and Anti-static design where Hazardous areas with handling of flammable fuels, gases or chemicals are in use.Technical Data :

- Size Range: DN 50(2") – 200(8")

- Pressure rating : ASME Class 150 to 300

- Temperature range : Upto 260 deg. C

- Seat : PTFE / Carbon Reinforced PTFE

- End Connections : Flanged ASME B16.5

- With & Without ISO PAD

- MOC : WCB, PTFE, CF8, 304 S/S, 316 S/S, MS, CF8M, SS, Carbon R'PTFE

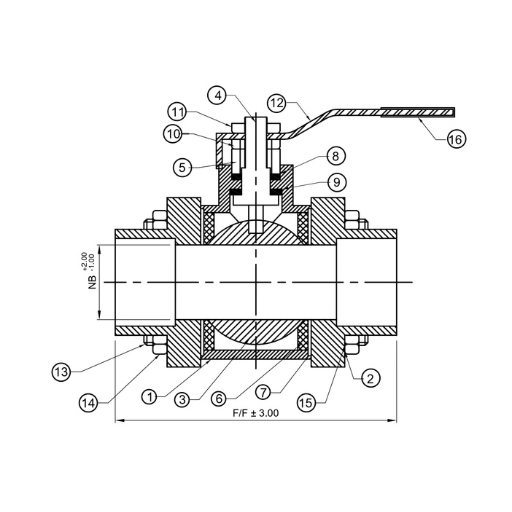

Ball Valves Three Piece, Full Bore (Screw End, Socket Weld) (150#, 300#, 600#, 800#)

Technical Data :

| Design Std. | As per ISO 17292 & BS 5351 |

| End Connection | Screwed End/Socket Weld |

| Testing & Std. | As per API 598 / ISO 5208 |

| Size, 150# | 15 mm to 50 mm (1/2" to 2") |

Material (MOC)

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Adaptor | WCB / CF8 / CF8M |

| 3 | Ball | CF8 / CF8M |

| 4 | Steam | SS304 / SS316 |

| 5 | Gland | SS304 / SS316 |

| 6 | Seat Ring | PTFE / GFT /CFT |

| 7 | Body Seal | PTFE / GFT /CFT |

| 8 | Gland Packing | PTFE / GFT /CFT |

| 9 | Steam Seal | PTFE / GFT /CFT |

| 10 | Gland Nut | MS/SS304 |

| 11 | Lever Nut | MS/SS304 |

| 12 | Lever | MS/SS |

| 13 | Stud | MS/SS304 |

| 14 | Stud Nut | MS/SS304 |

| 15 | Stud Washer | MS/SS304 |

| 16 | Lever Sleeve | PVC |

Dimensions 150#

| Size | NB | F/F | Thread Type |

| 15 | 12.5 | 62.5 | BSP/NPT/SW |

| 20 | 19.0 | 74.0 | BSP/NPT/SW |

| 25 | 25.0 | 87.0 | BSP/NPT/SW |

| 40 | 38.0 | 109.0 | BSP/NPT/SW |

| 50 | 50.0 | 110.0 | BSP/NPT/SW |

All Dimensions are in mm

Ball Valves Three Piece, Full Bore, Flange end (150#, 300#)

Technical Data :

| Design Std. | As per ISO 17292 & BS 5351 |

| End Connection | Flanged End |

| Testing Std. | As per API 598 or ISO 5208 |

| Size 150# & 300# | 15 mm to 300 mm (1/2" to 12") |

MATERIALS (MOC)

| Sr. No. | Description | Material |

| 1 | Body | CI /WCB / CF8 / CF8M |

| 2 | Adaptor | CI / WCB / CF8 / CF8M |

| 3 | Ball | CF8 / CF8M |

| 4 | Stem | SS304 / SS316 |

| 5 | Gland | SS304 / SS316 |

| 6 | Seat Ring | PTFE / GFT / CFT |

| 7 | Body Seal | PTFE / GFT / CFT |

| 8 | Gland Packing | PTFE / GFT / CFT |

| 9 | Stem Seal | PTFE / GFT / CFT |

| 10 | Gland Nut | MS / SS304 |

| 11 | Lever Nut | MS / SS304 |

| 12 | Lever | MS / SS |

| 13 | Stud | Ms / SS304 |

| 14 | Stud Nut | Ms / SS304 |

| 15 | Stud Washer | Ms / SS304 |

| 16 | Lever Washer | PVC |

DIMENSIONS 150#

| Size | Dia D | PCD | F/F |

| 15 | 90 | 60.5 | 108 |

| 20 | 100 | 70 | 117 |

| 25 | 110 | 79.5 | 127 |

| 40 | 125 | 98.5 | 165 |

| 50 | 150 | 120.5 | 178 |

| 65 | 180 | 139.5 | 191 |

| 80 | 190 | 152.5 | 203 |

| 100 | 230 | 190.5 | 229 |

| 150 | 280 | 241.5 | 267 |

| 200 | 345 | 298.5 | 292 |

| 250 | 405 | 362 | 330 |

| 300 | 485 | 432 | 356 |

DIMENSIONS 300#

| Size | Dia D | PCD | F/F |

| 15 | 95 | 66.5 | 140 |

| 20 | 115 | 82.5 | 152 |

| 25 | 125 | 89 | 165 |

| 40 | 155 | 114.5 | 190 |

| 50 | 165 | 127 | 216 |

| 65 | 190 | 149 | 241 |

| 80 | 210 | 168.5 | 283 |

| 100 | 255 | 200 | 305 |

| 150 | 320 | 270 | 403 |

| 200 | 380 | 330 | 419 |

| 250 | 445 | 387.5 | 457 |

| 300 | 520 | 451 | 502 |

All dimensions are in mm.

Double Window Sight Glass (PN10, PN16)

Applications:

Industrial facilities, oil refineries, bath soap manufacturing plane, gas industries, petrochemical complex, high viscous process media, building construction, environmental water treatments, synthetics, plastic and resin industries, polymer manufacturing plant, food industries (chocolate, sauce etc.), fertilizer industries etc.Technical Data :

| Design Std. | As per BS 5352 |

| Testing Std. | As per API 598 |

| End Connection | As per ANSI B16.5 |

| Size | 1/2” to 6” (15 mm to150 mm) |

| Size | 2" to 18", Class 150, 300 |

| Pressure rating | PN10 / PN16 |

| Maximum working pressure | 10 Kg/cm2 |

| Test pressure | 20 Kg/cm2 |

Dimensions

| Size | A | B | C |

| 15 | 153 | 51 | 137 |

| 20 | 153 | 51 | 137 |

| 25 | 153 | 51 | 137 |

| 40 | 178 | 64 | 146 |

| 50 | 190 | 76 | 190 |

| 75 | 229 | 102 | 232 |

| 100 | 299 | 127 | 283 |

| 150 | 406 | 191 | 368 |

All dimensions are in mm.

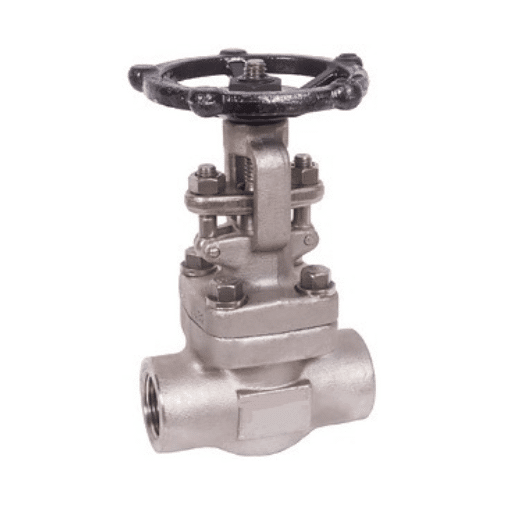

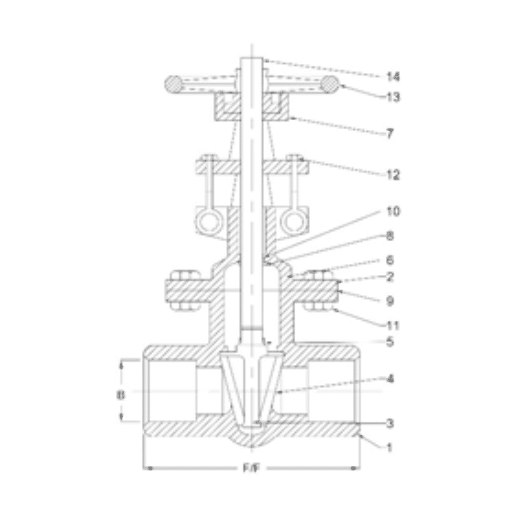

GATE VALVE, Screw End (150#, 300#)

| Design Std. | As per BS 5352/ ASME B16.34 |

| End Connection | Screw End |

| Testing & Std. | As per API 598 / ISO 5208 |

| Size, 150# | 15 mm to 50 mm (1/2" to 2") |

Bill Of Material

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Bonnet | WCB / CF8 / CF8M |

| 3 | Wedge | WCB (13% CR) / CF8 / CF8M |

| 4 | Seat Ring | SS410 (13% CR) / CF8 / CF8M |

| 5 | Stem | SS410 / SS304 / SS316 |

| 6 | Gland | SS410 / SS304 / SS316 |

| 7 | Yoke Sleeve | SS410 / SS304 / SS316 |

| 8 | Back Seat Bush | CS/CF8/CF8M |

| 9 | Gasket | EN8 |

| 10 | Gland Packing | MS/SS |

| 11 | Bonet Stud | MALLEABLE IRON |

| 12 | Bolt | MS |

| 13 | Hand wheel | SPW SS304 GRAPHITE FILLED |

| 14 | Hand wheel Nut | GRAPHITE |

Dimensions 150#

Technical Data

| Size | F/F | B |

| 15 | 85 | 21.7 |

| 20 | 92 | 27.1 |

| 25 | 106 | 33.8 |

| 30 | 122 | 42.6 |

| 40 | 127 | 48.5 |

| 50 | 140 | 50.8 |

All dimensions are in mm.

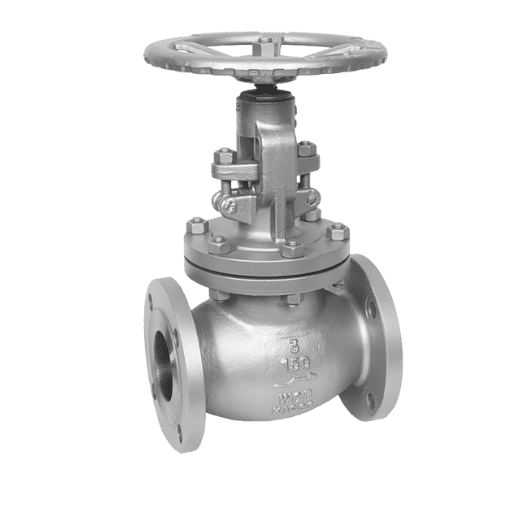

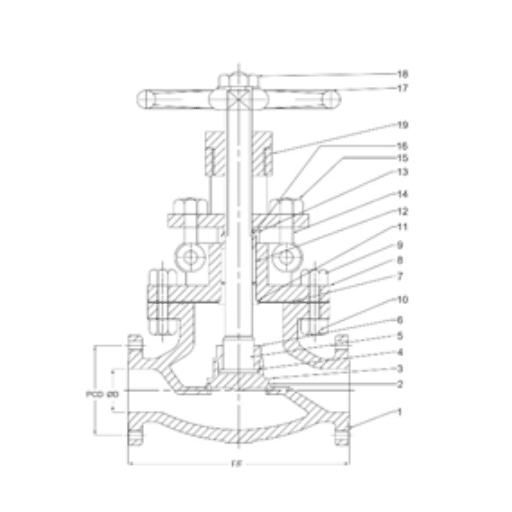

Globe Valve – Flanged End (150#, 300#)

TECHNICAL DATA

| Design Std. | As per BS 1873 / ASME B 16.34 |

| End Connection | Flanged End |

| Testing & Std. | As per API 598 or ISO 5208 |

| Size, 150# | 25 mm to 300 mm (1” to 12”) |

| Size, 300# | 50 mm to 300 mm (2” to 12”) |

Bill Of Material

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Body seat | SS410 (13% CR)/CF8/CF8M |

| 3 | Disc | WCB +13% CR STEEL |

| 4 | Disc washer | 13% CR STEEL |

| 5 | Stem | SS410 / SS304 / SS316 |

| 6 | Disc Stem Nut | 13% CR STEEL |

| 7 | Gasket | SPW SS304 GRAPHITE FILL |

| 8 | Bonnet | WCB/CF8/CF8M |

| 9 | Stud | ASTM A193 Gr. B7 |

| 10 | Stud Nut | ASTM A194 Gr. B2H |

| 11 | Back Seat Bush | SS410/SS304/SS316 |

| 12 | Spacer | 13% CR STEEL |

| 13 | Packing | GRAPHITE |

| 14 | Eye Bolt | MS/SS |

| 15 | Eye Bolt Nut | MS/SS |

| 16 | Gland | SS410/SS304/SS316 |

| 17 | Hand Wheel | MALLEABLE IRON |

| 18 | Hand Wheel Nut | MS |

| 19 | Yoke Sleeve | EN8 |

Dimensions 150#

| Size | Dia D | PCD | F/F |

| 25 | 110 | 79.5 | 127 |

| 40 | 125 | 98.5 | 165 |

| 50 | 150 | 120.5 | 203 |

| 65 | 180 | 139.5 | 216 |

| 80 | 190 | 152.5 | 241 |

| 100 | 230 | 190.5 | 292 |

| 150 | 280 | 241.5 | 406 |

| 200 | 345 | 298.5 | 495 |

| 250 | 405 | 362 | 622 |

| 300 | 485 | 432 | 698 |

Dimensions 300#

| Size | Dia D | PCD | F/F |

| 50 | 165 | 127 | 267 |

| 65 | 190 | 149 | 292 |

| 80 | 210 | 168.5 | 318 |

| 100 | 255 | 200 | 356 |

| 150 | 320 | 270 | 444 |

| 200 | 380 | 330 | 559 |

| 250 | 445 | 387.5 | 622 |

| 300 | 520 | 451 | 711 |

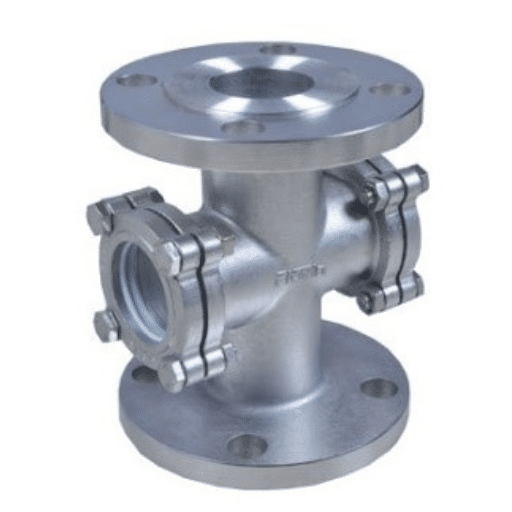

POT-BASKET TYPE STRAINER (ANSI 150#, 300#)

Applications:

Strainer can be used in liquid as well as gas line, Regulator and valve protection, steam traps protections, flow meter and pump protections, heat exchanger and refrigeration set protection, Suitable for Hazardous environments. Y-Strainers and pot basket type strainers is a device for mechanically removing unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element. Where the amount of material to be removed from the flow is relatively small, resulting in long intervals between screen cleanings, the strainer screen is manually cleaned by shutting down the line and removing the strainer cap.Technical Data :

| Design Std. | As per ASME B16.34 |

| Testing Std. | As per API 598 |

| End Connection | Flanged Drill as per ANSI B16.5 |

| Material | Body : IS 2062, Seal : NBR / PTFE / Graphite + SS, Mesh : SS |

| Shell Wall Thickness | As per ANSI B16.34 |

| Size | 2" to 18", Class 150, 300 |

Dimensions 150#

| Size | F/F | A | B |

| 50 | 320 | 190 | 285 |

| 80 | 360 | 200 | 320 |

| 100 | 400 | 210 | 360 |

| 125 | 460 | 230 | 430 |

| 150 | 510 | 240 | 430 |

| 200 | 560 | 280 | 530 |

| 250 | 810 | 420 | 635 |

| 300 | 890 | 430 | 715 |

Dimensions 300#

| Size | F/F | A | B |

| 50 | 380 | 200 | 305 |

| 80 | 420 | 235 | 400 |

| 100 | 475 | 260 | 405 |

| 125 | 510 | 275 | 435 |

| 150 | 620 | 295 | 490 |

| 200 | 630 | 345 | 560 |

| 250 | 900 | 390 | 690 |

| 300 | 1000 | 440 | 770 |

All dimensions are in mm.