POT-BASKET TYPE STRAINER (ANSI 150#, 300#)

Applications:

Strainer can be used in liquid as well as gas line, Regulator and valve protection, steam traps protections, flow meter and pump protections, heat exchanger and refrigeration set protection, Suitable for Hazardous environments.

Y-Strainers and pot basket type strainers is a device for mechanically removing unwanted solids from liquid, gas or steam lines by means of a perforated or wire mesh straining element. Where the amount of material to be removed from the flow is relatively small, resulting in long intervals between screen cleanings, the strainer screen is manually cleaned by shutting down the line and removing the strainer cap.

Technical Data :

| Design Std. | As per ASME B16.34 |

| Testing Std. | As per API 598 |

| End Connection | Flanged Drill as per ANSI B16.5 |

| Material | Body : IS 2062, Seal : NBR / PTFE / Graphite + SS, Mesh : SS |

| Shell Wall Thickness | As per ANSI B16.34 |

| Size | 2″ to 18″, Class 150, 300 |

Dimensions 150#

| Size | F/F | A | B |

| 50 | 320 | 190 | 285 |

| 80 | 360 | 200 | 320 |

| 100 | 400 | 210 | 360 |

| 125 | 460 | 230 | 430 |

| 150 | 510 | 240 | 430 |

| 200 | 560 | 280 | 530 |

| 250 | 810 | 420 | 635 |

| 300 | 890 | 430 | 715 |

Dimensions 300#

| Size | F/F | A | B |

| 50 | 380 | 200 | 305 |

| 80 | 420 | 235 | 400 |

| 100 | 475 | 260 | 405 |

| 125 | 510 | 275 | 435 |

| 150 | 620 | 295 | 490 |

| 200 | 630 | 345 | 560 |

| 250 | 900 | 390 | 690 |

| 300 | 1000 | 440 | 770 |

All dimensions are in mm.

General Notes :

- Customization and automation as per customer requirements.

- Certificate of compliance to EN10204 Type 3.1 as standard.

- Safety stock as per customer requirements.

- 100% factory tested and inspected valves as per standard.

- Other trims also available as per customer requirements.

- Support to customers for other product requirements from sources.

- Consult to Factory for Other Details.

Related products

Armstrong Design Envelope 9521 Integrated Plant Control System (IPC 9521)

- Applications-Automated chiller plant control for optimizing variable primary flow water-cooled chiller plants. The 9521 IPC works in a variable primary configuration and keeps the entire plant including water-cooled chillers, cooling towers, chilled water and condenser pumps running smoothly.

- Description-The Armstrong Integrated Water-Cooled Chiller Plant Control System (IPC) boosts energy efficiencies of new and existing chiller plant installations to leading class levels. The IPC 9521 works with all variable primary configurations, keeping the entire plant – including water-cooled chillers, cooling towers, chilled water and condenser pumps – running at optimum performance and occupant comfort.

- Configuration-Integrates with all brands of chillers, pumps, and automation systems. Installs directly with chiller plant equipment. If preferred, the IPC connects seamlessly with any central building automation system (BAS) maintaining full control of the chilled water plant through the BAS

- Performance range-Controls up to five chillers, five cooling towers and five pumps. No limitations in plant size and cooling capacity.

- Power Range-No limitations in plant cooling capacity

Armstrong Suction Guides

- Applications-HVAC-system pumping; general purpose pumping; industrial/process pumping (water or glycol based).

- Description-The Armstrong Suction Guides (SG) are multi-function pump fittings that provide a 90° elbow, guide vanes, and an in-line strainer. Suction guides reduce pump installation cost and floor space requirements.

- Materials (MOC)-Cast Iron, ductile iron; grooved, flanged or threaded connections

- Performance range-Suitable for all Armstrong commercial pumps and pumping systems

- Temperature-230°F (110°C)

- Size-1.5” to 20” (40 mm to 500 mm)

Ball Valves One Piece Full, Bore Screw end (150#)

Technical Data :

| Design Std. | As per ISO 17292 & BS 5351 |

| End Connection | Screwed End |

| Testing & Std. | As per API 598 / ISO 5208 |

| Size, 150# | 15 mm to 50 mm (1/2" to 2") |

MATERIAL (MOC)

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Cap | WCB / CF8 / CF8M |

| 3 | Ball | CF8 / CF8M |

| 4 | Steam | SS304 / SS316 |

| 5 | Gland | SS304 / SS316 |

| 6 | Seat Ring | PTFE / GFT /CFT |

| 7 | Body Seal | PTFE / GFT /CFT |

| 8 | Gland Packing | PTFE / GFT /CFT |

| 9 | Gland Nut | MS/SS304 |

| 10 | Lever Nut | MS/SS304 |

| 11 | Lever | MS/SS |

Dimensions 150#

| Size | NB | F/F | Thread Type |

| 15 | 12.5 | 58.8 | BSP/NPT |

| 20 | 19.0 | 68.5 | BSP/NPT |

| 25 | 25.0 | 76.5 | BSP/NPT |

| 32 | 32.0 | 90.0 | BSP/NPT |

| 40 | 38.0 | 100.0 | BSP/NPT |

| 50 | 50.0 | 118.0 | BSP/NPT |

All Dimensions are in mm

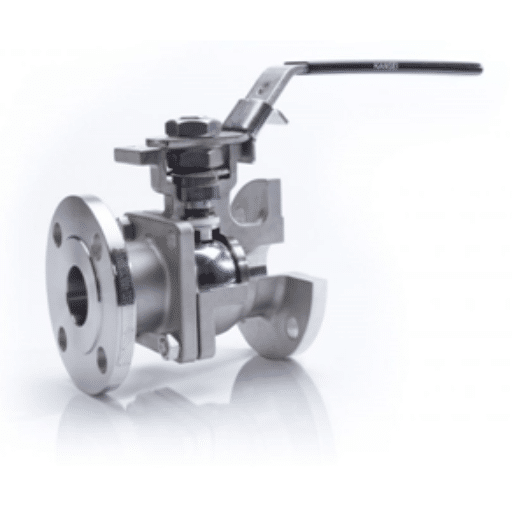

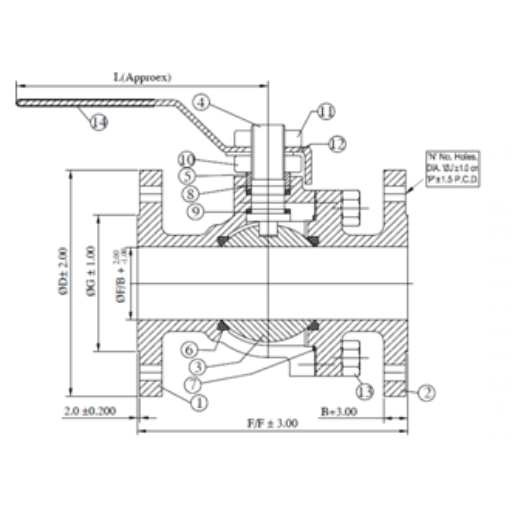

Ball Valves Two Piece, Metal Seated (150#, 300#)

Description

Kansei product KMS (Two-piece metal seated ball valve) in metal seated design as an additional option to our soft seated full port flanged series. This option increases the temperature rating to 750°F (399°C) and enhances wear resistance, while maintaining the proven safety and reliability of existing valves.Technical Data :

- Size Range: DN 15 (1/2”) – DN 200 (8”)

- Pressure: ASME Class 150 & 300

- Temperature range: Up to 400 deg. C

- Seat : SS 304 / SS316

- End Connections : Flanged ASME B16.5

- With ISO PAD

| Design Std. | As per ISO 17292 & BS 5351 |

| End Connection | Flanged End |

| Testing Std. | As per API 598 or ISO 5208 |

| Size 150# & 300# | 15 mm to 300 mm (1/2" to 12") |

MATERIALS (MOC)

| Sr. No. | Description | Material |

| 1 | Body | CI /WCB / CF8 / CF8M |

| 2 | Cap | CI / WCB / CF8 / CF8M |

| 3 | Ball | CF8 / CF8M |

| 4 | Stem | SS304 / SS316 |

| 5 | Gland | SS304 / SS316 |

| 6 | Seat Ring | SS304 / SS316 |

| 7 | Body Seal | PTFE / GFT / CFT |

| 8 | Gland Packing | PTFE / GFT / CFT |

| 9 | Stem Seal | PTFE / GFT / CFT |

| 10 | Gland Nut | MS / SS304 |

| 11 | Lever Nut | MS / SS304 |

| 12 | Lever | MS / SS |

| 13 | Stud & Nut | Ms / SS304 |

| 14 | Lever Sleeve | PVC |

| 15 | End Cap | PVC |

DIMENSIONS 150#

| Size | Dia D | PCD | F/F |

| 15 | 90 | 60.5 | 108 |

| 20 | 100 | 70 | 117 |

| 25 | 110 | 79.5 | 127 |

| 40 | 125 | 98.5 | 165 |

| 50 | 150 | 120.5 | 178 |

| 65 | 180 | 139.5 | 191 |

| 80 | 190 | 152.5 | 203 |

| 100 | 230 | 190.5 | 229 |

| 150 | 280 | 241.5 | 267 |

| 200 | 345 | 298.5 | 292 |

| 250 | 405 | 362 | 330 |

| 300 | 485 | 432 | 356 |

DIMENSIONS 300#

| Size | Dia D | PCD | F/F |

| 15 | 95 | 66.5 | 140 |

| 20 | 115 | 82.5 | 152 |

| 25 | 125 | 89 | 165 |

| 40 | 155 | 114.5 | 190 |

| 50 | 165 | 127 | 216 |

| 65 | 190 | 149 | 241 |

| 80 | 210 | 168.5 | 283 |

| 100 | 255 | 200 | 305 |

| 150 | 320 | 270 | 403 |

| 200 | 380 | 330 | 419 |

| 250 | 445 | 387.5 | 457 |

| 300 | 520 | 451 | 502 |

All dimensions are in mm.

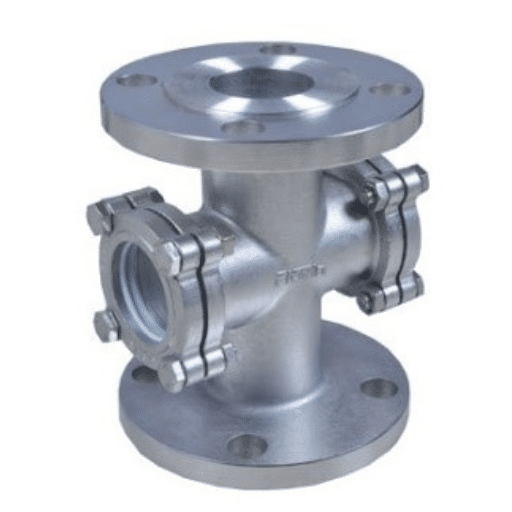

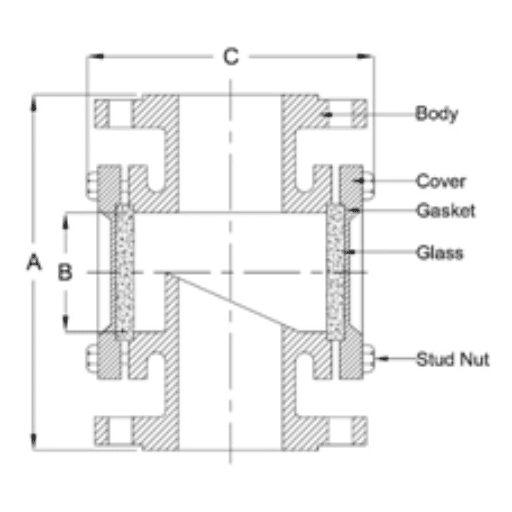

Double Window Sight Glass (PN10, PN16)

Applications:

Industrial facilities, oil refineries, bath soap manufacturing plane, gas industries, petrochemical complex, high viscous process media, building construction, environmental water treatments, synthetics, plastic and resin industries, polymer manufacturing plant, food industries (chocolate, sauce etc.), fertilizer industries etc.Technical Data :

| Design Std. | As per BS 5352 |

| Testing Std. | As per API 598 |

| End Connection | As per ANSI B16.5 |

| Size | 1/2” to 6” (15 mm to150 mm) |

| Size | 2" to 18", Class 150, 300 |

| Pressure rating | PN10 / PN16 |

| Maximum working pressure | 10 Kg/cm2 |

| Test pressure | 20 Kg/cm2 |

Dimensions

| Size | A | B | C |

| 15 | 153 | 51 | 137 |

| 20 | 153 | 51 | 137 |

| 25 | 153 | 51 | 137 |

| 40 | 178 | 64 | 146 |

| 50 | 190 | 76 | 190 |

| 75 | 229 | 102 | 232 |

| 100 | 299 | 127 | 283 |

| 150 | 406 | 191 | 368 |

All dimensions are in mm.

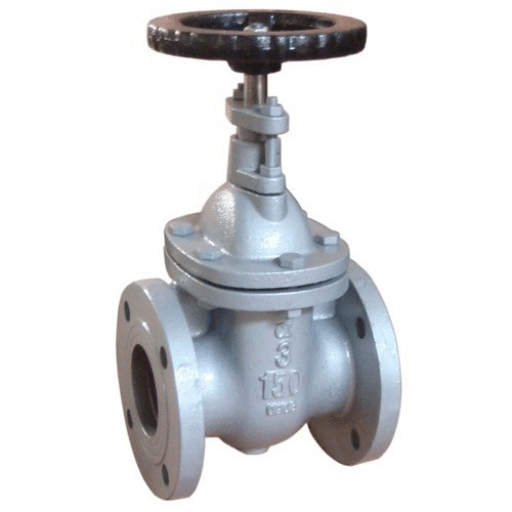

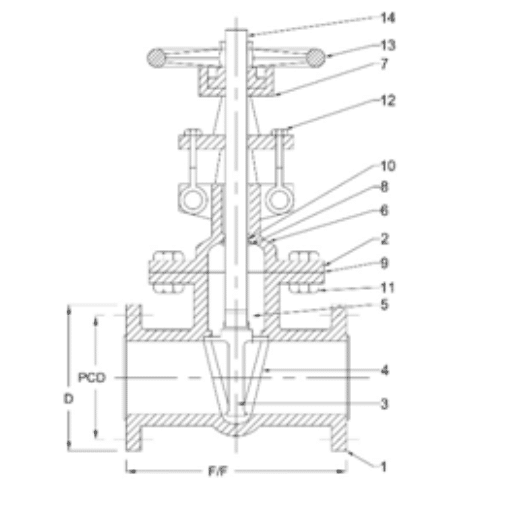

GATE VALVE, Flanged End (150# , 300#)

Technical Data

| Design Std. | As per BS 1414 |

| End Connection | Flanged End |

| Testing & Std. | As per API 598 / ISO 5208 |

| Size, 150# & 300# | 15 mm to 300 mm (1/2" to 12") |

Bill Of Material

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Bonnet | WCB / CF8 / CF8M |

| 3 | Wedge | WCB (13% CR) / CF8 / CF8M |

| 4 | Seat Ring | SS410 (13% CR) / CF8 / CF8M |

| 5 | Stem | SS410 / SS304 / SS316 |

| 6 | Gland | SS410 / SS304 / SS316 |

| 7 | Yoke Sleeve | SS410 / SS304 / SS316 |

| 8 | Back Seat Bush | CS/CF8/CF8M |

| 9 | Gasket | EN8 |

| 10 | Gland Packing | MS/SS |

| 11 | Bonet Stud | MALLEABLE IRON |

| 12 | Bolt | MS |

| 13 | Hand wheel | SPW SS304 GRAPHITE FILLED |

| 14 | Hand wheel Nut | GRAPHITE |

Dimensions 150#

| Size | Dia D | PCD | F/F |

| 15 | 90 | 60.5 | 108 |

| 20 | 100 | 70 | 117 |

| 25 | 110 | 79.5 | 127 |

| 40 | 125 | 98.5 | 165 |

| 50 | 150 | 120.5 | 178 |

| 65 | 180 | 139.5 | 191 |

| 80 | 190 | 152.5 | 203 |

| 100 | 230 | 190.5 | 229 |

| 150 | 280 | 241.5 | 267 |

| 200 | 345 | 298.5 | 292 |

| 250 | 405 | 362 | 330 |

| 300 | 485 | 432 | 356 |

Dimensions 300#

| Size | Dia D | PCD | F/F |

| 15 | 95 | 66.5 | 140 |

| 20 | 115 | 82.5 | 152 |

| 25 | 125 | 89 | 165 |

| 40 | 155 | 114.5 | 190 |

| 50 | 165 | 127 | 216 |

| 65 | 190 | 149 | 241 |

| 80 | 210 | 168.5 | 283 |

| 100 | 255 | 200 | 305 |

| 150 | 320 | 270 | 403 |

| 200 | 380 | 330 | 419 |

| 250 | 445 | 387.5 | 457 |

| 300 | 520 | 451 | 502 |

All dimensions are in mm.

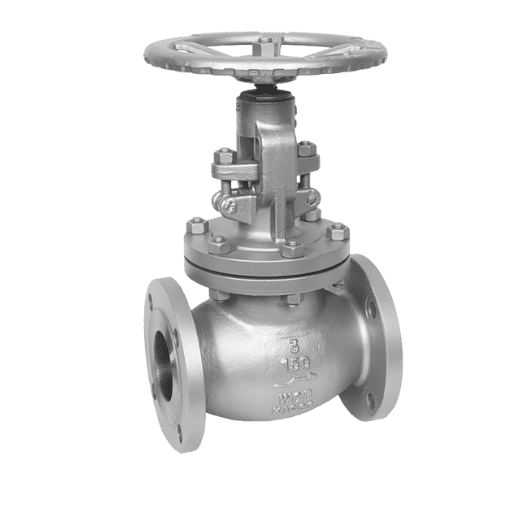

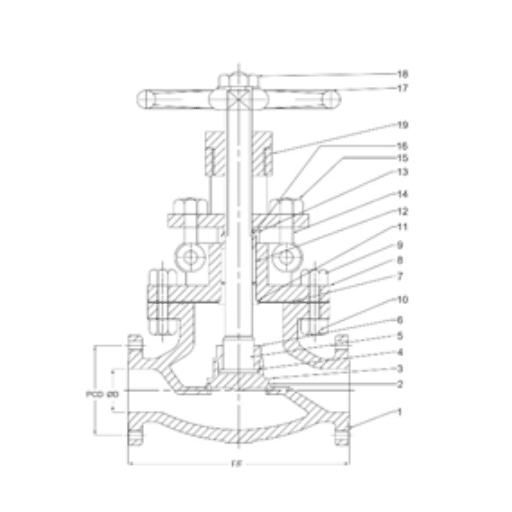

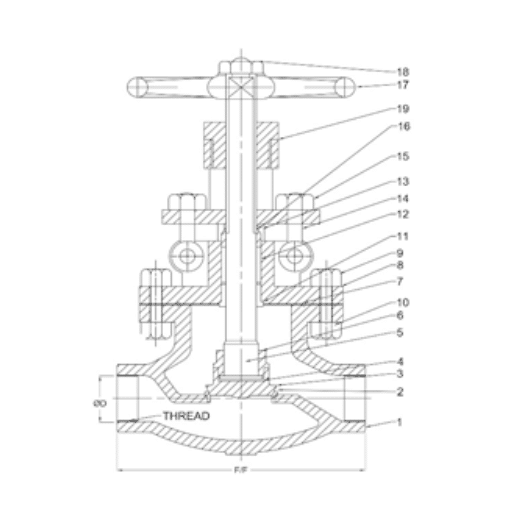

Globe Valve – Flanged End (150#, 300#)

TECHNICAL DATA

| Design Std. | As per BS 1873 / ASME B 16.34 |

| End Connection | Flanged End |

| Testing & Std. | As per API 598 or ISO 5208 |

| Size, 150# | 25 mm to 300 mm (1” to 12”) |

| Size, 300# | 50 mm to 300 mm (2” to 12”) |

Bill Of Material

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Body seat | SS410 (13% CR)/CF8/CF8M |

| 3 | Disc | WCB +13% CR STEEL |

| 4 | Disc washer | 13% CR STEEL |

| 5 | Stem | SS410 / SS304 / SS316 |

| 6 | Disc Stem Nut | 13% CR STEEL |

| 7 | Gasket | SPW SS304 GRAPHITE FILL |

| 8 | Bonnet | WCB/CF8/CF8M |

| 9 | Stud | ASTM A193 Gr. B7 |

| 10 | Stud Nut | ASTM A194 Gr. B2H |

| 11 | Back Seat Bush | SS410/SS304/SS316 |

| 12 | Spacer | 13% CR STEEL |

| 13 | Packing | GRAPHITE |

| 14 | Eye Bolt | MS/SS |

| 15 | Eye Bolt Nut | MS/SS |

| 16 | Gland | SS410/SS304/SS316 |

| 17 | Hand Wheel | MALLEABLE IRON |

| 18 | Hand Wheel Nut | MS |

| 19 | Yoke Sleeve | EN8 |

Dimensions 150#

| Size | Dia D | PCD | F/F |

| 25 | 110 | 79.5 | 127 |

| 40 | 125 | 98.5 | 165 |

| 50 | 150 | 120.5 | 203 |

| 65 | 180 | 139.5 | 216 |

| 80 | 190 | 152.5 | 241 |

| 100 | 230 | 190.5 | 292 |

| 150 | 280 | 241.5 | 406 |

| 200 | 345 | 298.5 | 495 |

| 250 | 405 | 362 | 622 |

| 300 | 485 | 432 | 698 |

Dimensions 300#

| Size | Dia D | PCD | F/F |

| 50 | 165 | 127 | 267 |

| 65 | 190 | 149 | 292 |

| 80 | 210 | 168.5 | 318 |

| 100 | 255 | 200 | 356 |

| 150 | 320 | 270 | 444 |

| 200 | 380 | 330 | 559 |

| 250 | 445 | 387.5 | 622 |

| 300 | 520 | 451 | 711 |

GLOBE VALVE, Screw End (800#)

TECHNICAL DATA

| Design Std. | As per BS 5352 / ASME B 16.34 |

| End Connection | Screw End |

| Testing & Std. | As per API 598 or ISO 5208 |

| Size, 800# | 15 mm to 50 mm (1/2” to 2”) |

Bill Of Material

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Body seat | SS410 (13% CR)/CF8/CF8M |

| 3 | Disc | WCB +13% CR STEEL |

| 4 | Disc washer | 13% CR STEEL |

| 5 | Stem | SS410 / SS304 / SS316 |

| 6 | Disc Stem Nut | 13% CR STEEL |

| 7 | Gasket | SPW SS304 GRAPHITE FILL |

| 8 | Bonnet | WCB/CF8/CF8M |

| 9 | Stud | ASTM A193 Gr. B7 |

| 10 | Stud Nut | ASTM A194 Gr. B2H |

| 11 | Back Seat Bush | SS410/SS304/SS316 |

| 12 | Spacer | 13% CR STEEL |

| 13 | Packing | GRAPHITE |

| 14 | Eye Bolt | MS/SS |

| 15 | Eye Bolt Nut | MS/SS |

| 16 | Gland | SS410/SS304/SS316 |

| 17 | Hand Wheel | MALLEABLE IRON |

| 18 | Hand Wheel Nut | MS |

| 19 | Yoke Sleeve | EN8 |

Dimensions 800#

| Size | F/F | B |

| 15 | 85 | 21.7 |

| 20 | 92 | 27.1 |

| 25 | 106 | 33.8 |

| 30 | 122 | 42.5 |

| 40 | 127 | 48.6 |

All dimensions are in mm.