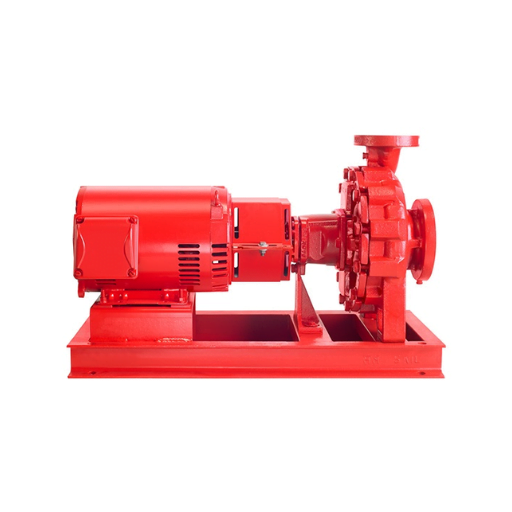

Armstrong 4030 End Suctionbase Mounted Pumps

- Applications — HVAC-system pumping; light industrial/ process pumping

- Description — The Armstrong 4030 horizontal end-suction (ES) pumps are engineered to substantially reduce cost over competitor designs across installation, operation, and lifetime maintenance. High-efficiency NEMA-premium motors ensure low energy consumption and cost.

- Materials (MOC) — Cast iron, ductile iron, or bronze casing, Cast iron or bronze impeller

- Configuration Inside — single spring mechanical seal.

- Performance range — Up to 5,000 USgpm (315 L/s) flow; up to 600 ft (180 m) head

- Temperature — 250°F (121°C)

- Power Range — 0.33 hp to 300 hp (0.25 kW to 200 kW)

- Size — 1″ to 8” (25 mm to 200 mm)

Description

Benefits & Features

Low installed cost

- ANSI/HI 1.3.5 rigid free-standing baseplate eliminates grouting.

- Pre-lubricated and sealed deep-groove ball bearings for convenient installation. (simply pipe, align, wire and start)

Low energy consumption

- Armstrong 4030 pumps are equipped with high-efficiency NEMA-premium motors for significant reduction in energy consumption and cost

- All motors are suitable for inverter-fed service

Low operating and maintenance cost

- Armstrong 4030 pumps are equipped with high-efficiency NEMA-premium motors for significant reduction in energy cost

- ANSI-style centerline discharge casing eliminates air binding

- Sintered silicon carbide mechanical seal seat for longer life

- Confined casing gasket eliminates blow-outs

- Universal replacement seals, bearings, and motors available locally world-wide

Related products

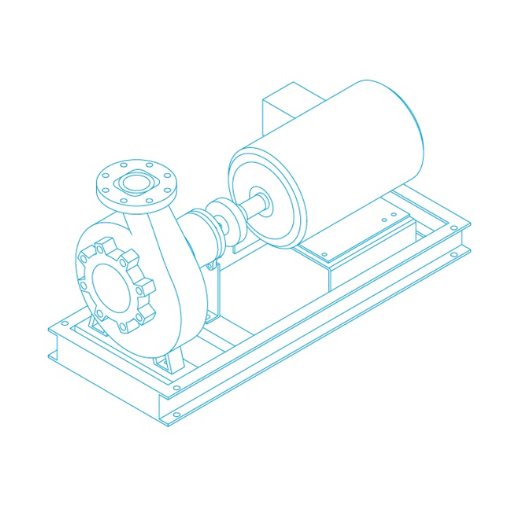

Armstrong 4280 Motor Mounted Pumps

- Applications-HVAC-system pumping; light industrial / process pumping.

- Description-The Armstrong 4280 horizontal end-suction pumps are equipped with close-coupled motors to minimize footprint requirements.

- Materials(MOC)-Cast iron, ductile iron, or bronze casing, Cast iron or bronze impeller.

- Configuration-Inside single-spring mechanical seal

- Performance range-Up to 2,000 USgpm (125 L/s) flow; up to 400 f (120 m)

- Temperature-250°F (121°C)

- Power Range-0.33 hp to 60 hp (0.25 kW to 45 kW)

- Size-1" to 6” (25 mm to 150 mm)

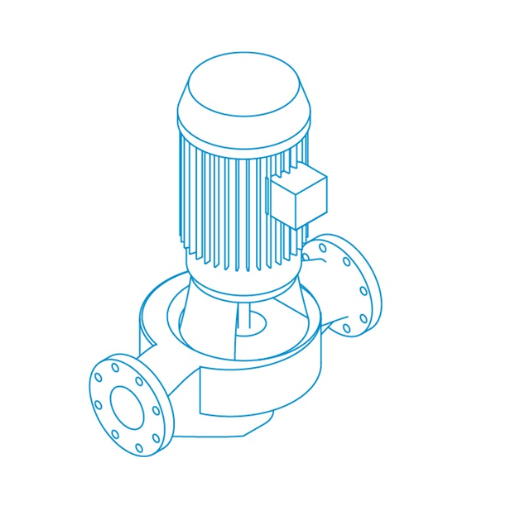

Armstrong 4380 vertical in-line pumps

- Applications-HVAC-system pumping; light industrial/ process pumping. (water or glycol based)

- Description-The Armstrong 4380 pipe-mounted pumps are designed for space-saving installation and long service life.

- Materials(MOC)-Cast iron or ductile iron casing, Silicon sintered carbide mechanical seal, Cast iron or bronze impeller.

- Configuration-Inside single-spring mechanical seal.

- Performance range-Up to 2,500 USgpm (160 L/s) flow; up to 300 ft (90 m) head

- Temperature-250°F (121°C)

- Power Range-0.33 hp to 60 hp (0.25 kW to 45 kW)

- Size-1.5″ to 8″ (40 mm to 200 mm)

Armstrong Design Envelope 4300 Pumps

- Applications-HVAC-system pumping and control; general purpose pumping; industrial/process pumping and control. (water or glycol based)

- Description-Pipe-mounted UL 778 pumping unit with integrated intelligent controls for space-saving installation and superior energy performance. Saves up to 75% in energy over comparable traditional constant speed or variable frequency operated pump installations. Remote services through internet to enhance reliability and sustain optimal performance over life of pumps.

- Materials(MOC)-Ductile iron e-coated casing, Stainless steel impeller, Sintered silicon carbide mechanical seal

- Configuration-On-board Intelligent Variable Speed controls with Sensorless control. Split-coupling design and outside balanced or inside single spring mechanical seal. Controls enclosure UL type 12 or UL type 4X for outdoor applications. 0.33-50hp range standard with DEPM motors that reduce losses by more than 20% over NEMA Premium efficiency. Network capable for remote performance management services.

- Performance range-25 to 25,000 USgpm (1.5 to 1500 L/s) flow; 10 to 300 ft (3 to 90 m) head (composite curves available)

- Temperature-300oF (150oC)

- Power Range-0.33 hp to 1250 hp (0.25 kW to 900 kW)

- Size-1″ to 20″ (25 mm to 500 mm)

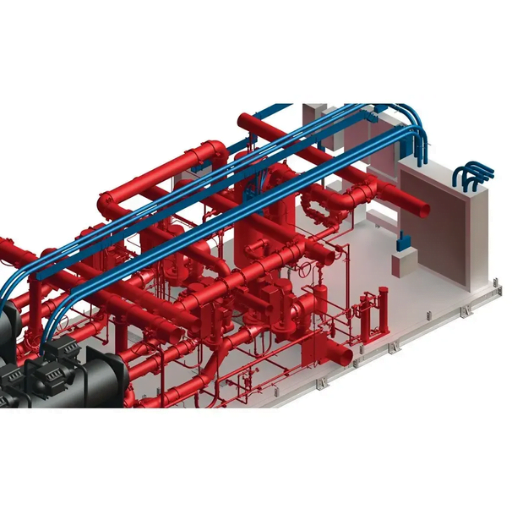

Armstrong Design Envelope Chilled-Water Integrated Plant Package

- Applications-Commercial and industrial chilled-water cooling systems.

- Description-The Armstrong Chilled-Water Integrated Plant Package combines all the equipment needed to deliver chilled water to medium to large size buildings at superior energy efficiency. The factory-assembled plant includes pumps, integrated controls, water-cooled chillers and the requisite instrumentation, valves and sensors. IPP complies with all ASHRAE 189.1 requirements and exceeds ASHRAE 90.1.

- Configuration-Variable primary with variable condenser flow. Catalogue-based pre-engineered solutions or designed to customer specification. BMS communications protocol available

Armstrong Design Envelope Integrated Pumping System (IPS 4000)

- Applications-Multi-pump control for heated – or chilled – water system optimization in buildings.

- Description-The Design Envelope Integrated Pumping System (IPS 4000) is an advanced multi-zone control that directly integrates with pumping units to optimize energy performance, system handling, and installation.

- Materials (MOC)-Enclosure, circuitry, software

- Configuration-Integrates seamlessly with Armstrong Design Envelope pumps in a headered configuration.

- Performance range-Up to 8 pumps, 16 zones (variable primary, secondary or tertiary) and 8 flow sensitive equipment (variable primary) IPS 4001w / IPS 4501w for up to 3 pumps, 3 zones and 3 flow sensitive equipment IPS 4002w / IPS 4502w for up to 4 pumps, 6 zones and 4 flow sensitive equipment IPS 4003w / IPS 4503w for up to 6 pumps, 12 zones and 6 flow sensitive equipment IPS 4004w / IPS 4504w for up to 8 pumps, 16 zones and 8 flow sensitive equipment

- Power Range-No limitations in system size and capacity.

- Size-No limitations in system size.

Armstrong Expansion Tanks

- Applications-Pressure stabilization in water based mechanical systems such as booster installations, boiler systems, and chiller plants

- Description-Armstrong Expansion Tanks are designed to reduce tank sizes by up to 80% over standard designs. Expansion tanks use compressed air to maintain system pressures by accepting and expelling the changing volume of water as it heats and cools. Diaphragm or bladder tank designs isolate the expanded water from the pressure controlling air cushion – which is pre-charged at the factory and can be adjusted in the field to meet final system requirements

- Materials (MOC)-Carbon steel (shell), heavy duty Butyl (diaphragm)

- Performance range-AET plain steel expansion tanks: 15 to 525 USgpm flow. AX diaphragm expansion tanks: 8 to 211 USgpm flow. Type L bladder type expansion tanks: 10 to 1056 USgpm flow.

Armstrong Firepak Vertical In-line

- Applications-Fire-protection of buildings and other built infrastructure.

- Description-The Armstrong Vertical In-line (VIL) FirePak line features the full range of VIL fire pumps with electric motor and controller. All mounted, piped, and wired on a base at the factory. The complete package is designed to fit through a standard door.

- Materials (MOC)-Metal base, piping, pump, and control panel; switchgear; electric motor.

- Configuration-Options available include jockey pump and jockey pump controller. 50 Hz and 60 Hz designs. UL, ULC, and/or FM certification

- Performance range-50 – 1500 USgpm

Armstrong Suction Guides

- Applications-HVAC-system pumping; general purpose pumping; industrial/process pumping (water or glycol based).

- Description-The Armstrong Suction Guides (SG) are multi-function pump fittings that provide a 90° elbow, guide vanes, and an in-line strainer. Suction guides reduce pump installation cost and floor space requirements.

- Materials (MOC)-Cast Iron, ductile iron; grooved, flanged or threaded connections

- Performance range-Suitable for all Armstrong commercial pumps and pumping systems

- Temperature-230°F (110°C)

- Size-1.5” to 20” (40 mm to 500 mm)