Adept Electromagnetic Flowmeter – MagProbe 6450

Insertion Type

Introduction

Electromagnetic Flow measurement has been in use around the world for 50 years and more, as witnessed by the popularity of these meters that continues unabated in virtually all sectors of industry. Electromagnetic Flowmeters can be used to measure all electrically conductive liquids (> 5 µS/cm) with or without solids, e.g. water, wastewater, sludge, slurries, pastes, acids, alkalis, juices, fruit pulp, etc.

Insertion Type Electromagnetic Flowmeter is suitable for the most demanding applications. They are based on Faraday’s law of Electromagnetic Induction. The meter features sensor tube and ball valve assembly.

Salient Features

Applications

Product Selection Guide

| Parameters | Specifications |

|---|---|

| Nominal dia (mm) | > 100 |

| Working pressure (kg/cm2) | 20 |

| Working temperature | Up to 120°C |

| Electrode material | SS 316L Std.* |

| Sensor lining | NA |

| Display version | Integral/Remote |

| Measuring tube material | SS 316 Std.* |

| Sensor housing material | NA |

| End connection | NA |

| Flange standard | NA |

| Measuring range | 0.2 to 12 m/sec. Bidirectional |

| Accuracy % of measured value | ±2% |

| Repeatability | ±0.2% of Span |

| Display | 2 line LCD |

| Display units | All standard engineering units in m³, litre, gallon, ft³, imperial gallon |

| Output | Std. 4 – 20 mA* |

| Power supply | 12 – 60 V DC or 80 – 300 V AC/DC Solar powered |

| Protection class for sensor | Std. IP 68 |

| Protection class for transmitter | IP 67 |

| Cable length for remote | Std. 10 m* |

| Installation | Insertion type with use of isolating ball valve assembly on pipeline |

Advanced Technology Flow Instrumentation Solutions

Adept is one of the largest manufacturers of Electromagnetic and Ultrasonic Flowmeters in India and has been acquired by Yokogawa Electric Corporation. Yokogawa provides advanced solutions in the areas of measurement, control, and information to customers across a broad range of industries, including energy, chemicals, materials, pharmaceuticals and food. The acquisition will help to leverage the strong presence of Adept in the Indian market with the technological prowess of Yokogawa.

Adept range of Flowmeters is characterised by advanced technology, excellent quality and high reliability to ensure accurate and precise measurement of fluid flow. We have a large manufacturing facility with two factories operational in Pune, India, certified with IMS (Integrated Management System). This is backed by our in-house Design & Development Centre and the Calibration Laboratory certified with ISO/IEC 17025:2017. More than 70,000 Flowmeters supplied by us are operational in over 25 countries across the world, meeting the stringent requirements of different sectors. The reliability of our products and the dependability of our services are evident from repeat orders from our customers. Over 40% of our business comes from existing customers.

Related products

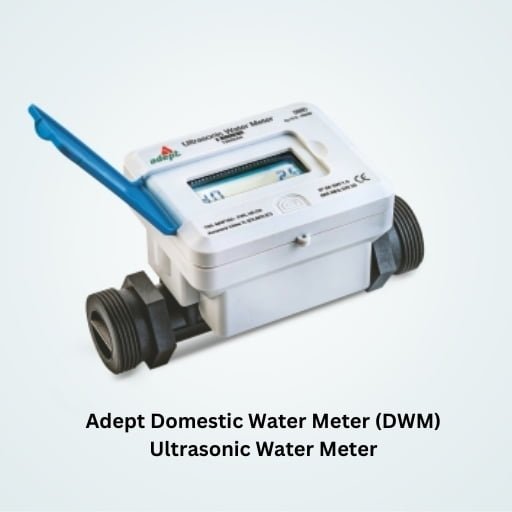

Adept Domestic Water Meter DWM – Ultrasonic Water Meter

Ideal Product for Smart City Water Utilities

Introduction

IoT Ready

Adept Electromagnetic Flowmete – MagBP 6440

Introduction

Salient Features

Applications

Product Selection Guide

| Parameters | Specifications |

|---|---|

| Nominal dia (mm) | 10 to 1000 |

| Working pressure (kg/cm2) | 10, 16, 25, 40 |

| Working temperature | Up to 55°C |

| Electrode material | SS 316L Std.* |

| Sensor lining | Std. Rubber* |

| Display version | Integral/Remote |

| Measuring tube material | SS 304 Std.* |

| Sensor housing material | Std. CS* |

| End connection | Flange/Wafer/Tri-clamp/SMS |

| Flange standard | ANSI 150* |

| Measuring range | 0.2 to 12 m/sec. Bidirectional |

| Accuracy % of measured value | ±0.5% |

| Repeatability | ±0.2% of Span |

| Display | LCD |

| Display units | All standard engineering units in m³, litre, gallon, ft³, imperial gallon |

| Output | Pulse* |

| Power supply | Battery powered (5 years’ battery life) |

| Protection class for sensor | Std. IP 65 Option IP 67/IP 68 for flow tube in remote type |

| Protection class for transmitter | IP 67 |

| Cable length for remote | Std. 10 m* |

| Installation | Inline flanged type |

Adept Electromagnetic Flowmete – EcoMag 6420

Introduction

Salient Features

Applications

Product Selection Guide

| Parameters | Specifications |

|---|---|

| Nominal dia (mm) | 10 to 200 |

| Working pressure (kg/cm2) | 5 |

| Working temperature | Up to 55°C |

| Electrode material | SS 316L Std.* |

| Sensor lining | NA |

| Display version | Integral/Remote |

| Measuring tube material | HDPE |

| Sensor housing material | HDPE |

| End connection | Flange |

| Flange standard | ANSI 150* |

| Measuring range | 0.2 to 12 m/sec. Bidirectional |

| Accuracy % of measured value | ±1% |

| Repeatability | ±0.2% of Span |

| Display | 2 line LCD |

| Display units | All standard engineering units in m³, litre, gallon, ft³, imperial gallon |

| Output | Std. 4 – 20 mA* |

| Power supply | 12 – 60 V DC or 80 – 300 V AC/DC Solar powered |

| Protection class for sensor | Std. IP 65 Option IP 67/IP 68 for flow tube in remote type |

| Protection class for transmitter | IP 67 |

| Cable length for remote | Std. 10 m* |

| Installation | Inline flanged type |

Adept Electromagnetic Flowmeter MagFlow 6410

Introduction

Salient Features

Applications

Product Selection Guide

| Parameters | Specifications |

|---|---|

| Nominal dia (mm) | 10 to 3000 |

| Working pressure (kg/cm2) | 10, 16, 25, 40 |

| Working temperature | Integral PTFE – 120°C Remote PTFE – 180°C Others – 70°C |

| Electrode material | SS 316L Std.* |

| Sensor lining | Std. Rubber* |

| Display version | Integral/Remote |

| Measuring tube material | SS 304 Std.* |

| Sensor housing material | Std. CS* |

| End connection | Flange/Wafer/Tri-clamp/SMS |

| Flange standard | ANSI 150* |

| Measuring range | 0.2 to 12 m/sec. Bidirectional |

| Accuracy % of measured value | ±O.5% (±O.2% consult factory) |

| Repeatability | ±0.2% of Span |

| Display | 2 line LCD |

| Display units | All standard engineering units in m3, litre, gallon, ft3, imperial gallon |

| Output | Std. 4 – 20 mA* |

| Power supply | 12 – 60 V DC or 80 – 300 V AC/DC Solar powered |

| Protection class for sensor | Std. IP 65 Option IP 67/IP 68 for flow tube in remote type |

| Protection class for transmitter | IP 67 |

| Cable length for remote | Std. 10 m* |

| Installation | Inline flanged type |

Adept IoT Gateway 5000

Introduction

Specifications

Adept Ultrasonic Flowmeter – UFM 6710

Introduction

Salient Features

Applications

Product Selection Guide

| Parameters | Specifications |

|---|

| Transmitter | |

| Power supply | 24 V DC ± 20% 110 V AC ± 15% 240 V AC ± 15% Solar powered |

| Velocity | ±12 m/sec. Bidirectional |

| Display | 2 lines, 16 characters, LCD with backlight, flow rate, velocity, totaliser |

| Units | User configurable English/Metric |

| Totaliser | FWD, NET, REV, BATCH (Gallons, ft³, barrels, lbs, m³) |

| Output | 4 – 20 mA DC Std.* |

| Accuracy | ±1% of reading @ rate > 0.5 m/sec. (Optional ±0.5% of reading) |

| Repeatability | 0.2% of Span |

| Protection class | IP 65, IP 67 |

| Dimensions | 251x190x96 mm |

| Weight | < 2.5 kg |

| Security | Keypad lockout, access code enabled |

| Sensor | |

| Suited temp. – Std. | -40°C to 120°C |

| Suited temp. – High | -40°C to 250°C |

| Pipe size | |

| S Sensor | 15 – 80 mm |

| M Sensor | 50 – 700 mm |

| L Sensor | 400 – 4570 mm |

| Dimensions | |

| S Sensor | 45x30x30 mm |

| M Sensor | 60x45x45 mm |

| L Sensor | 80x70x55 mm |

| Weight | |

| S Sensor | < 0.3 kg |

| M Sensor | < 0.5 kg |

| L Sensor | < 1.0 kg |

| Protection class | IP 65, IP 67, IP 68 |

| Cable length | 6 m std. can be extended up to 300 m |

| Flexible belts | SS belt according to pipe size |

| Portable case | NA |

Adept Ultrasonic Flowmeter – UFM 6730

Introduction

Salient Features

Applications

Product Selection Guide

| Parameters | Single Path | Two Path | Four Path |

|---|

| General | |||

| No. of Sensors | 2 | 4 | 8 |

| Operating principle | Transit time technology | Transit time technology | Transit time technology |

| Operating pressure | 20 kg/cm² max | 20 kg/cm² max | 20 kg/cm² max |

| Application | Raw, clear, sewage water & homogeneous liquids | Raw, clear, sewage water & homogeneous liquids | Raw, clear, sewage water & homogeneous liquids |

| Transmitter | |||

| Power supply | 24 V DC ± 20% 110 V AC ± 15% 240 V AC ± 15% Solar powered | 24 V DC ± 20% 110 V AC ± 15% 240 V AC ± 15% Solar powered | 24 V DC ± 20% 110 V AC ± 15% 240 V AC ± 15% Solar powered |

| Velocity | ±12 m/sec. Bidirectional | ±12 m/sec. Bidirectional | ±12 m/sec. Bidirectional |

| Display | 2 lines, 16 characters LCD with backlight flow rate, velocity, totaliser | 2 lines, 16 characters LCD with backlight flow rate, velocity, totaliser | 2 lines, 16 characters LCD with backlight flow rate, velocity, totaliser |

| Units | User configurable English/Metric | User configurable English/Metric | User configurable English/Metric |

| Totaliser | FWD, NET, REV | FWD, NET, REV | FWD, NET, REV |

| Output – Analog | 4 – 20 mA Std.* | 4 – 20 mA Std.* | 4 – 20 mA Std.* |

| Accuracy | ±1% of reading @ rate >0.5 m/sec. | ±0.5% of reading @ rate >0.5 m/sec. | ±0.5% of reading @ rate >0.5 m/sec. |

| Repeatability | 0.2% of Span | 0.2% of Span | 0.2% of Span |

| Protection class | IP 65 | IP 65 | IP 65 |

| Dimensions | 251X190X96 mm | 500x400x300 mm | 500x400x300 mm |

| Weight | < 2.5 kg | < 4.5 kg | < 6.5 kg |

| Security | Keypad lockout, access code enabled | Keypad lockout, access code enabled | Keypad lockout, access code enabled |

| Self diagnostic feature | Available | Available | Available |

| Facility to measure and display each path velocity | NA | Available | Available |

| Ability to work even though one or more path does not work | NA | Available | Available |

| Flow and totaliser unit programmability | Available | Available | Provided |

| Password protection for configuration data | Available | Available | Available |

| Totaliser value retention in the event of power fail condition | Available | Available | Available |

| RS 485 Modbus RTU Protocol | Available | Available | Available |

| Lightening protection units | Available | Available | Available |

| Sensor | |||

| Suited temp. – Std. | -40°C to 120°C | -40°C to 120°C | 40°C to 120°C |

| Pipe size | 50 – 6000 mm dia | 350 – 6000 mm dia | 1000 – 6000 mm dia |

| Protection class | IP 65, IP 67, IP 68 | IP 65, IP 67, IP 68 | IP 65, IP 67, IP 68 |

| Sensor dimensions | 186 mm with 20 mm bore size | 186 mm with 20 mm bore size | 186 mm with 20 mm bore size |

| Weight | < 1.5 kg | < 1.5 kg | < 1.5 kg |

| Cable length | 6 m std. can be extended up to 300 m | 6 m std. can be extended up to 300 m | 6 m std. can be extended up to 300 m |

Adept Ultrasonic Flowmeter – UFM 6740

Introduction

Salient Features

Applications

Product Selection Guide

| Parameters | Specifications |

|---|---|

| Technical characteristics | Low power consumption, digital process technology with stable piezoelectric sensor |

| Accuracy | ±1% of reading (Optional ±0.5%) |

| Repeatability | 0.2% of Span |

| Display | Total flow, flow rate, velocity, working time & date, signal intensity, quality & battery status |

| Output | RS 485, 4 – 20 mA, Pulse for total flow (All outputs need external power supply 24 V DC) |

| Communication interface | GSM, RS 485 (Modbus RTU), UART |

| Operation | Inside keypad available |

| Sampling period | 0.5 sec |

| Environment temp. | Up to 65°C |

| Water temp. | 5 to 70°C |

| Power supply | Li-ion battery, solar powered |

| Enclosure class | IP 68 |

| Pipe size | DN 40 – 600 |

| Flange standard | ANSI, IS, DIN PN, BS |

| Pressure transmitter | Range 0-16 kg/cm², IP 68, 1/2″ male threaded, accuracy 0.25% |