PVDF/ PFA lined Centrifuge Pumps, PFA Pump Manufacturer

Lined Pumps – PFA Pump Manufacturer

We are a recognised PFA Pump Manufacturer in India and Exporter in India. Moniba Pumps uses a hi-tech lining process, free from adhesive bonding. This eliminates peeling off of the lining from the metal body, different form other lined products. Rigorous quality checks through out the lining process ensures years of trouble. free operation. These pumps are available in a variety of lining materials to withstand severe corrosion and temperature conditions.

Moniba, being the one of the leading and most recommended PFA Pump Manufacturer in India, has to maintain the quality measures of all the Pumps manufactured by them. The quality of the Motor pumps outstanding as their lack of wear parts minimizes the chances of maintainance to the least. We are a superior PFA Lined Pumps Manufacturer in India consume comparitively less power. They are available in many kinds of variants can be provided to the clients as per their specifications. The recent trend in the plant engineering is highly focused on world scale plants.

Moniba Pumps is an magnificent and distinguished industrial unit for being the most recognized firm and its low-upkeep PFA Pumps is perceived on a worldwide level. Dependability and wellbeing are the most huge parts that prompt successful tasks at Moniba and we flourish with these standards to convey the best outcomes to our customers. The PFA Pump is analyzed legitimately by highly qualified Inspection Officers to give the customers the best, all things considered.

Moniba Pumps has been a benchmark in the country when it comes to manufacturing and supplying best quality of PFA Pumps. We have thus, been a succesful PFA Pump Exporter in Indiain the industry. Supplying the best quality of PFA Lined Pumps is our motto and we head to strive and spread our word in the entire globe.

Features:

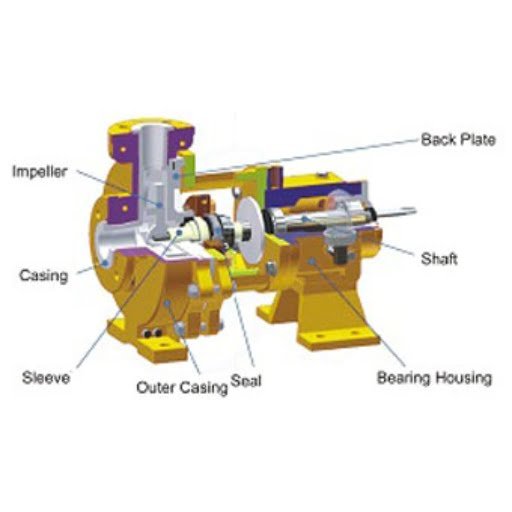

Moniba is considered the best PFA Pump Manufacturer in India in the category. The hi-tech lining process involves high prssure moulding at high temperature to ensure uniform thickness of lining free from cavaties, air pockets, cold flows etc. A unique feature is the dove-tail grooves provided on the metal casing and backplate. This ensures a firm grip between the metal and lining material. A dynamically balanced, solid moulded, semi-open impeller with metallic insert gives mechanical strength and durability.

- Material of Construction – The PPK Series lined pumps are made available in materials like – LINING : PFA, FEP, PVDF.

- Casing and Backplate – Cast Steel, Stainless Steel 316. The M.O.C. is selected on the basis of the compatibility and temperature of the fluid handled as per the specific requirement. The pumps are available for high head and capacity.

- Shaft – Shafts are designed for high torque and power transmission with minimum vibration, deflection and noise level.

- Sleeve – The sleeves are glided over the shaft, protecting it from corrosive application. Materials: Ceramic, Alloy-20, Hasteloy-c, Hasteloy-B, Monel, Titanium, Silicon Carbide etc.

- Seals – Mechanical Seals Available with an option of being mounted either externally or internally. The pumps are fitted with specially designed single or double seals with suitable faces alongwith quenching arangement & necessary API Plans if required.

- Gaskets – To ensure firm sealing, PTFE gaskets are provided at the joints.

- Casing / Backplate – The wetted areas are lined with compatible polymer. The casing has a rugged foot- mounting which is capable of handling high pressure, piping loads and system pressure. Concentric dove-tail grooves ensure a firm grip between the metal body and lining.

- Impeller – The impeller has a radial semi- open design, with large contoured flow passages. It is dynamically balanced and is provided with back vanes to reduce axial thrust for improved and elongated product life.

Applications and Industries Served –

- Chemical processing

- Drugs and Pharmaceuticals

- Petrochemicals

- Effluent Treatment

- Food processing

- Fumes scrubbing

- Agro chemicals

- Tanneries

- Perfumeries

- Detergents and caustics

- Breweries

- Acid pickling

- Dyes and pigments

- Paper and Pulp industries

- Photographic processing

New Close Impeller Design For Higher Efficiency

- Metal armoured protected volute casing design

- Solid Injection Moulded Volute Casing back plate & impeller

- Split metal armour design provides strength to volute & ease of replacement

- Consistent shaft quality provider longer life to mechanical seals & shaft sleeves

- PTFE envelop Gasket with EPDM incert provider effective sealing even at higher tempreture

- Pumps are provided with std. Single Machanical Seals & high alumina Ceramic Sleeves. However other option are also available based on fluid pumped, temperature process requirement. Alloy-20 / Monel/ Titanium/Hastalloys B or C

- In House mould making facility

- In House injection moulding facility with latest, state of art moulding machines with thermo-state Controller

- In House component machining & dynamic balancing facility provides consistent Quality

- Each pump is tested on Electronic state of art test bench & test report is provided.

- Shorter delevery periods & quick after sales service.

- PVDF Moulded component thickness

Volute Casing– 8 mm to 14 mm

Back Plates– 13 mm to 16 mm

Impeller– 14 mm to 20 mm

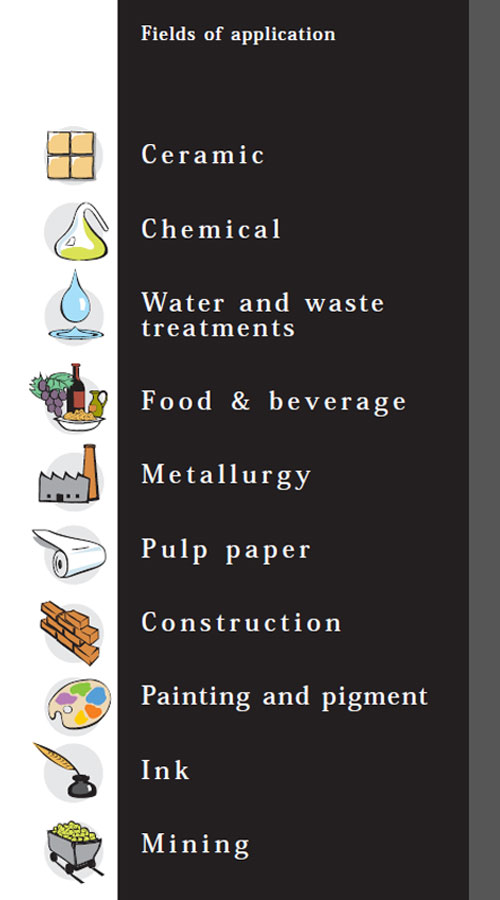

INDUSTRIAL APPLICATION OF PP PUMP:

PP UPTO 90 DEG C

PVDF UPTO 130 DEG C

PFA ABOVE 130 DEG C

INDUSTRIES SERVED:

MONIBA supports an array of customer specifications with products that are easily acceptable to meet specific process requirements.

Pickling of Mild Steel / Stainless Steel:

Pickling of metals to obtain protection against corrosion and to remove undesired surface layers like oxides (scales, rust) is done by chemical or electrochemical treatment. MONIBA pumps provide unrivalled performance and service life for Hydrochloric or Sulphuric Acid pickling applications.

Sulphuric Acid Plants:

Sulphuric Acid is reckoned among the most basic substances of chemical technology. Sulphuric acid is produced by thermal dissociation of waste acids, by suitable reconditioning of sulphur containing waste gases or by use of sulphur containing minerals. MONIBA pumps are used for diluted, concentrated acids & for SO, 2 SO scrubber applications.

Chloro-Alkali Plants:

Chloro-Alkali electrolysis is one of the most important processes in the chemical industry and provides the basic, chlorine, caustic soda and hydrogen. MONIBA pumps are successfully used for Brine, Sulphuric Acid, Sodium Hypochlorite and Caustic Soda applications

Gas Scrubbers:

Gas scrubbers are designed for applications requiring the removal of various types of contaminants from gas streams. Typical applications for contaminant removal include noxious or toxic fumes from chemical processes. MONIBA pumps have been recommended extensively for fiberglass re-inforced gas scrubbers. Particulate removal from gas streams is accomplished with the use of venture scrubbers where ANTICO pumps have proven track record

Chemicals and Fine Chemicals Processing

Nowadays fine chemicals are increasingly gaining importance. This sector of the chemical industry comprises the pharmaceutical, biochemistry, biotechnology and many other chemical processing industries. MONIBA pumps fitted with the latest shaft sealing technologies have surpassed all customer expectations in handling Volatile Hazardous Air Pollutants.

Electroplating (Metal Finishing) Plants:

Electroplating is the process of using electrical current to reduce captions of a desired material from a solution and coat a conductive object with a thin layer of the material, such as a metal. MONIBA pumps have been deployed extensively to circulate electrolyte containing one or more dissolved metal salts majorly for electroplating of auto components.

Waste Water Treatment

Effluent of chemical processing plants treated with caustic thus neutralizing the effluent. Effluent treatment facilities have ion exchange resins to remove ions from aqueous solutions. Hydrochloric acid is used to rinse the captions from the resins thus producing dematerialized water. MONIBA pumps have become a standard equipment for acid, caustic & DM water applications amongst water treatment industry.

Advantages

- Volute & Impellers are injection Molding PVDF / PFA / FEP material with smooth hydraulic passage.

- Shaft are available with sleeves of different materials compatible with the liquid handled

- Pumps are avaible with externally mounted balanced mech seal or teflon gland packing or internal mech seal with elastomer bellows

- Less space required & easy to handle

- Excellent mechanical properies over a wide range of temprature (23oC to 130oC)

- Abrasion resistance comparable to that of polyamide, and relatively low coefficient of friction.

- Smooth running and long service life of the mechanical seal.

- Epoxy paint to protect from external protection of pump.

- External cooling arrangement provided in pump for enhancement of mechanical seal life.

Specifications

This parameters depend on size of pump

| Capacity | Upto 400m3/hr |

| Head | Upto 100 meters |

| Power | Upto 55 HP |

| Max liquid temp. | 220oC |

| Max working pressure | 7Kg/cm2 |

| RPM | 2900/1440 |

| Solid % | Max 30% |

| Solid Size | Max 3mm |

Perforamance

| MONIBA ANAND ELECTRICALS PVT LTD | ||||||||||||

| Sr No. | Model | RPM | Graph no. | Q= m3/hr & H=meter | Shut off head in meter | |||||||

| 1 | MK-20 | 2900 | Q | 0 | 5 | 6.5 | 8.5 | 8.7 | 11 | 13 | 21 | |

| H | 21 | 18 | 16 | 14 | 12 | 9 | 6 | |||||

| 2 | MK-25 | 2900 | Q | 0 | 2.8 | 8.7 | 14.5 | 17 | 19 | 20 | 27 | |

| H | 27 | 25 | 20 | 15 | 12 | 10 | 8 | |||||

| 3 | MK-40 | 2900 | Q | 0 | 12 | 21 | 30 | 37 | 42 | 13 | 35 | |

| H | 35 | 30 | 25 | 20 | 18 | 15 | 44 | |||||

| 4 | MK-45 | 2900 | Q | 0 | 12 | 25 | 35 | 44 | 50 | 55 | 52 | |

| H | 52 | 48 | 42 | 36 | 30 | 24 | 18 | |||||

| 5 | MK-50 | 2900 | Q | 0 | 24 | 41 | 54 | 66 | 74 | 76 | 34 | |

| H | 34 | 30 | 25 | 20 | 15 | 12 | 11 | |||||

| 6 | MK-55 | 1440 | Q | 0 | 30 | 38 | 43 | 50 | 57 | 60 | 36 | |

| H | 36 | 30 | 27 | 25 | 20 | 18 | 16 | |||||

| 7 | MK-60 | 2900 | Q | 0 | 30 | 40 | 60 | 74 | 85 | 95 | 53 | |

| H | 53 | 50 | 48 | 42 | 36 | 30 | 24 | |||||

| 8 | MK-70 | 1440 | Q | 0 | 14 | 33 | 42 | 49 | 57 | 70 | 31 | |

| H | 31 | 30 | 27 | 25 | 23 | 20 | 15 | |||||

| 9 | MK-80 | 2900 | Q | 0 | 48 | 62 | 100 | 126 | 148 | 162 | 52 | |

| H | 52 | 50 | 48 | 42 | 36 | 30 | 24 | |||||

| 10 | MK-90 | 1440 | Q | 0 | 56 | 52 | 96 | 114 | 120 | 130 | 28 | |

| H | 28 | 25 | 23 | 20 | 18 | 15 | 13 | |||||

| 11 | MK-95 | 1440 | Q | 0 | 96 | 130 | 158 | 162 | 180 | 190 | 46 | |

| H | 46 | 40 | 35 | 30 | 28 | 25 | 23 | |||||

| 12 | MK-150 | 1440 | Q | 0 | 40 | 100 | 122 | 140 | 170 | 182 | 52 | |

| H | 52 | 50 | 45 | 42 | 40 | 35 | 32 | |||||

Note* – Higher capacity pumps available on request.

PVDF / PFA / FEP Pump Selection

| Chemical | Formula | PVDF |

| Acetate Solvents | CH3COOR | A |

| Acetaldehyde (Ethanal) | CH3CHO | A 150°F |

| Acetamide (Acetic Acid Amide) | CH3CONH2 | A 140°F |

| Acetic Acid _ Glacial | CH3COOH | A 120°F |

| Acetic Anhydride (Acetic Oxide) | (CH3CO)2O | B 70°F |

| Acetonitrile (Methyl Cyanide) | CH3CN | A |

| Acetophenone (Phenyl Methyl Ketone) | C6H5COCH3 | A |

| Acetyl Chloride | CH3COCl | A |

| Acetylene (Ethyne) | HC=CH | A |

| Acrylonitrile (Vinyl Cyanide) | CH2=CHCN | A |

| Adipic Acid (1,4-Butanedicarboxylic Acid) | HOOC(CH2)4 (COOH ) | A |

| Alcohols | R-OH | A |

| Allyl Alcohol (2-Propen-1-ol) | CH2CHCH2OH | A |

| Allyl Chloride (3-Chloropropene) | CH2=CHCH2CI | A |

| Alum (Aluminum Potassium Sulfate Dodecahydrate) | KAI(SO4)2 &1&2H2O | A |

| Aluminum Ammonium Sulfate (Alum) | AINH4(SO4)2 | A |

| Aluminum Bromide | AlBr3 | A |

| Aluminum Chloride | AlCl3 | A |

| Aluminum Fluoride | AlF3 | A |

| Aluminum Hydroxide (Alumina Trihydrate) | AI(OH)3 | A |

| Aluminum Nitrate | Al(NO3)3 &9H2O | A |

| Aluminum Potassium Sulfate (Potash Alum) | KAl(SO4)2 | A |

| Aluminum Sulfate (Cake Alum) | Al2(SO4)3 | A |

| Ammonia Anhydrous, Liquid | NH3 | A |

| Ammonium Bifluoride _ 10% | NH4HF2 | A |

| Ammonium Carbonate | (NH4)2CO3 | A |

| Ammonium Chloride (Sal Ammoniac) | NH4Cl | A |

| Ammonium Fluoride | NH4F | A |

| Ammonium Hydroxide (Aqua Ammonia) | NH4OH | A |

| Ammonium Metaphosphate | A | |

| Ammonium Nitrate | NH4NO3 | A |

| Ammonium Nitrite | NH4NO2 | A |

| Ammonium Persulfate | (NH4)2S2O8 | A |

| Ammonium Phosphate, Di-Basic | (NH4)2HPO4 | A |

| Ammonium Phosphate, Monobasic | (NH4)H2PO4 | A |

| Ammonium Phosphate, Tri-Basic | (NH4)3PO4&3H2O | A |

| Ammonium Sulfate | (NH4)2SO4 | A |

| Amyl (1-Pentanol) | C4H9CH2OH | A |

| Amyl Acetate (Banana Oil) | CH3CO2C5H11 | A 120°F |

| Amyl Alcohol (Pentyl Alcohol) | CH3(CH2)4OH | A |

| Amyl Chloride (Chloropentane) | CH3(CH2)4CI | A |

| Aniline (Aniline Oil) (Amino Benzene) | C6H5NH2 | A |

| Aniline Hydrochloride | C6H5NH2HCI | A |

| Animal Fats & Oils | A | |

| Antimony Trichloride | SbCI3 | A |

| Aqua Regia (Nitric & Hydrochloric Acid) | A | |

| Arsenic Acid | AsH3O4 | A |

| Asphalt | Hydrocarbons | A |

| Barium Carbonate | BaCO3 | A |

| Barium Chloride Dihydrate | BaCl2 &2H2O | A |

| Barium Hydroxide (Barium Hydrate) | Ba(OH)2 | A |

| Barium Nitrate | Ba(NO3)2 | A |

| Barium Sulfate (Blanc Fixe) | BaSO4 | A |

| Barium Sulfide | BaS | A |

| Beer | Water, carbonate | A 175°F |

| Beet Sugar Liquors (Sucrose) | A | |

| Benzaldehyde | C6H5CHO | A |

| Benzene (Benzol) | C6H6 | B |

| Benzene Sulfonic Acid | C6H5SO3H | B 100°F |

| Benzoic Acid (Benzene Carboxylic Acid) | C6H5COOH | A |

| Benzol (Benzene) | C6H6 | B |

| Benzol (Benzene) | C6H6 | B |

| Benzoyl Chloride | C6H5COCl | A |

| Benzyl (Phenylcarbinol) | C6H5CH2OH | A |

| Benzyl Alcohol | C6H5CH2OH | A |

| Benzyl Chloride (Chlorotoluene) | C6H5CH2Cl | A |

| Borax (Sodium Borate) | B4Na2O7 | A |

| Boric Acid (Boracic Acid) | H3BO3 | A |

| Brine (Sodium Chloride) | Salt water | A |

| Bromine _ Anhydrous | Br2 | A 150°F |

| Bromine Water | A | |

| Butadiene | C4H6 | A |

| Butane (LPG) (Butyl Hydride) | C4H10 | A |

| Buttermilk | Fats, water | A |

| Butyl (Butanol) | C3H7CH2OH | A |

| Butyl Acetate | CH3CO2(CH2)3CH3 | A 100°F |

| Butyl Alcohol (Butanol) | CH3(CH2)3OH | A |

| Butyl Amine (Aminobutane) | CH3(CH2)2CH2NH2 | B 70°F |

| Butyl Bromide | CH3(CH2)2CH2Br | A |

| Butyl Cellosolve | HOCH2CH2OC4H9 | B |

| Butyl Chloride (Chlorobutane) | CH3(CH2)3CL | A |

| Butyl Ether (Dibutyl Ether) | (CH3(CH2)3)2O | A 100°F |

| Butyl Stearate | CH3(CH2)16 CO2(CH2)3CH3 | A |

| Butylene (Butene) | C4H8 | A |

| Butyric Acid | CH3(CH2)2CO2H | A |

| Calcium Bisulfite | Ca(HSO3)2 | A |

| Calcium Carbonate (Chalk) | CaCO3 | A |

| Calcium Chlorate | Ca(ClO3)2 | A |

| Calcium Chloride (Brine) | CaCl2 &6H2O | A |

| Calcium Hydroxide (Slaked Lime) | Ca(OH)2 | A |

| Calcium Hypochlorite 20% (Calcium Oxichloride) | Ca(CIO)2 | A |

| Calcium Nitrate | Ca(NO3)2 | A |

| Calcium Sulfate (Gypsum) | CaSO4 | A |

| Calcium Sulfide | CaS | A |

| Cane Sugar Liquors | Sucrose, water | A |

| Caprylic Acid (Octanoic Acid) | CH3(CH2)6 COOH | A |

| Carbolic Acid (see Phenol) | C6H5OH | A 150°F |

| Carbon Dioxide (Carbonic Acid Gas) | CO2 | A |

| Carbon Disulfide (Carbon Bisulfide) | CS2 | A |

| Carbon Monoxide | CO | A |

| Carbon Tetrachloride (Tetrachloromethane) | CCL4 | A |

| Carbonated Beverages | CO2/H2O | A |

| Carbonic Acid (liquid) | H2CO3 | A |

| Cellosolve (Glycol Ethers) | HOCH2CH2OR | A |

| Chlorinated Water | A | |

| Chlorine Dioxide | CIO2 | A |

| Chlorine, Anhydrous Liquid | CI2 | A |

| Chlorine, Dry | CL2 | A |

| Chlorine, Wet | CI2/H2O | A |

| Chloroacetic Acid (Monochloroacetic Acid) | CICH2COOH | A |

| Chlorobenzene (Monochlorobenzene) | C6H5CI | A 150°F |

| Chloroform | CHCI3 | A |

| Chromic Acid _ 25%-50% | H2CrO4 | A 120°F |

| Chromic Acid _ Over 50% | H2CrO4 | A 120°F |

| Chromic Acid _ To 25% | H2CrO4 | A 120°F |

| Citric Acid | C6H8O7 H2O | A 250°F |

| Coke Oven Gas | H2(&5&3%), CH4 (&2&6%), N2 (&1&1%), CO (&7%) hydrocarbons(&3%) | A |

| Copper Acetate | Cu(c2H3O2)2 CuO &6H2O | A |

| Copper Chloride | CuCl2&2H2O | A |

| Copper Cyanide | CuCN | A |

| Copper Nitrate Hexahydrate | Cu(NO3)2&6H2O | A |

| Copper Sulfate (Blue Copperas) | CuSO4&5H2O | A |

| Corn Oil (Maize oil) | Glycerides of fatty acids | A |

| Cotton Seed Oil | A | |

| Cresylic Acid (Cresol) | C8H10O2 | A 150°F |

| Cyclohexane | C6H12 | A |

| Cyclohexanol | C6H11OH | A 150°F |

| Cyclohexanone | C6H10O | A |

| Decane | CH3(CH2)8CH3 | A |

| Denatured Alcohol | Ethanol and denaturant | A |

| Dextrose | C6H12O6 | A |

| Diacetone (Tyranton) | (CH3)2C(OH) CH2COCH3 | A |

| Dibutyl Amine | (C4H9)2NH | B 70°F |

| Diesel Oil (Fuel ASTM #2) | Hydrocarbons | A |

| Diethyl Amine | (CH3CH2)2NH | A |

| Diethyl Ether (Ether) | (CH3CH2)2O | A |

| Diethyl Sebecate | C14H26O4 | A 120°F |

| Diisobutylene | [HC=C(CH3)2]2 | A |

| Dimethyl Phthalate | C6H4(CO2CH3)2 | A 70°F |

| Diphenyl Oxides (Phenyl Ether) | C6H5OC6H5 | A |

| Dipropylene Glycol | (C3H6OH)2O | A |

| Epsom Salts (Magnesium Sulfate) | MgSO4 &7H2O | A |

| Ethyl (Ethanol) | CH3CH2OH | A |

| Ethyl Acetate | CH3COOC H2CH3 | A |

| Ethyl Acetoacetate (Acetoacetic Ester) | CH3COCH2 COOCH2CH3 | A 70°F |

| Ethyl Acrylate | CH2CHCO2CH2CH3 | B 70°F |

| Ethyl Alcohol (Ethanol) | CH3CH2OH | A |

| Ethyl Benzene | CH3CH2C6H5 | A |

| Ethyl Chloride (Chloroethane) | C2H5CI | A |

| Ethylene Chlorohydrin | CICH2CH2OH | A 70°F |

| Ethylene Diamine | (CH2)2(NH2)2 | B |

| Ethylene Dibromide (Ethylene Bromide) | Br(CH2)2Br | A |

| Ethylene Dichloride (Dutch Oil) | CI(CH2)2CI | A |

| Ethylene Glycol (Ethylene Alcohol, Glycol) | (CH2OH)2 | A |

| Ethylene Oxide | (CH2)2O | A |

| Fatty Acids | CnH2n+1COOH | A |

| Ferric Chloride | FeCI3 | A |

| Ferric Nitrate | Fe(NO3)3 | A |

| Ferric Sulfate | Fe2(SO4)3 | A |

| Ferrous Chloride | FeCI2 | A |

| Ferrous Sulfate | FeSO4 | A |

| Fluoboric Acid | HBF4 | A |

| Fluorine (Liquid) | F2 | A 70°F |

| Fluosilicic Acid (Sand Acid) | H2SiF6 | A |

| Formaldehyde (Formalin) | HCHO | A 120°F |

| Formic Acid | HCOOH | A |

| Freon 11 (Trichlorofluoromethane) | CCI3F | A |

| Freon 113 (Trichlorotrifluoroethane) (TF) | CI3CCF3 | A |

| Freon 114 (Dichlorotetrafluoroethane) | C2CI2F4 | A |

| Freon 114B2 (Dibromotetrafluoroethane) | C2Br2F4 | A |

| Freon 12 (Dichlorodifluoromethane) | CI2CF2 | A |

| Freon 21 (Dichlorofluoromethane) | FCHCI2 | A |

| Fruit Juices | Water, sucrose | A |

| Fuel Oils (ASTM #1 thru #9) | Hydrocarbons | A |

| Furfural (Ant Oil) | C5H4O2 | B 120°F |

| Furfuryl Alcohol | C5H6O2 | B 100°F |

| Gallic Acid | C6H(OH)3 COOH | A 70°F |

| Gasoline (Petrol) | Hydrocarbons | A |

| Gasoline (Unleaded) | C4 TO C12 hydrocarbons | A |

| Gelatin | Water soluble proteins | A |

| Glucose (Corn Syrup) | C6H12O6 | A |

| Glycerol (Glycerine) | C3H8O3 | A |

| Glycolic Acid | HOCH2COOH | A |

| Glycols | A | |

| Grape Juice | Water, sucrose | A |

| Heptane | C7H16 | A |

| Hexyl (1-Hexanol) | C5H11CH2OH | A |

| Hexyl Alcohol (1-Hexanol) | C6H13OH | A |

| Hydrobromic Acid | HBr | A |

| Hydrochloric Acid 10% (Muratic) | HCI | A |

| Hydrochloric Acid 20% (Muratic) | HCI | A |

| Hydrochloric Acid 30% (Conc.) | HCI | A |

| Hydrocyanic Acid (Formonitrile) | HCN | A |

| Hydrofluoric Acid (Conc.) Cold | HF | A |

| Hydrogen Fluoride _ Anhydrous | HF | A |

| Hydrogen Peroxide _ 10% | H2O2 | A |

| Hydrogen Peroxide _ 3% | H2O2 | A |

| Hydrogen Peroxide _ 30% | H2O2 | A |

| Hydrogen Sulfide (Wet) | H2S | A |

| Hydroquinone | C6H4(OH)2 | A |

| Hypochlorous Acid | HCIO | A |

| Iodine | I2 | A 150°F |

| Iodoform | CHI3 | A |

| Isobutyl (2-Methyl-1-Propanol) | C3H7CH2OH | A |

| Isobutyl Alcohol (Isobutanol) | (CH3)2 CHCH2OH | A |

| Isooctane (Trimethylpentane) | C8H18 | A |

| Isopropyl (2-Propanol) | H3CCH(OH)CH3 | A 150°F |

| Isopropyl Alcohol (Isopropanol) | CH3CH(OH)CH3 | A |

| Isopropyl Ether | (CH3)2CHOCH(CH3)2 | A 170°F |

| Jet Fuels (JP1 to JP6) (ASTM-A, A1 & B) | A | |

| Kerosine (Kerosene) | Hydrocarbons | A |

| Lactic Acid | CH3CHOHCOOH | A |

| Lard (Lard Oil) | Olein, stearin | A |

| Lead Acetate (Sugar of Lead) | Pb(CH3CO2)2 | A |

| Lead Chloride | PbCI2 | A |

| Lead Nitrate | Pb(NO3)2 | A |

| Linoleic Acid | C18H32O2 | A |

| Linseed Oil (Flaxseed Oil) | Glycerides | A |

| Lithium Bromide | LiBrH2O | A |

| Lubricating Oils (Petroleum) | Hydrocarbons | A |

| Lye (Potassium Hydroxide) | KOH | A 150°F |

| Magnesium Carbonate | MgCO3 | A |

| Magnesium Chloride | MgCI2O | A |

| Magnesium Hydroxide (Milk of Magnesia) | Mg(OH)2 | A |

| Magnesium Nitrate | Mg(NO3)2 &6H2O | A |

| Magnesium Sulfate (Epsom Salts) | MgSO4&7H2O | A |

| Maleic Acid | (CHCOOH)2 | A |

| Mercuric Chloride | HgCI2 | A |

| Mercuric Cyanide | Hg(CN)2 | A |

| Mercurous Nitrate | Hg(NO3)2 &2H2O | A |

| Mercury | Hg | A |

| Methane | CH4 | A |

| Methyl (Methanol) | CH3OH | A |

| Methyl Acrylate | CH2CHCO2CH3 | A 70°F |

| Methyl Alcohol (Methanol) | CH3OH | A |

| Methyl Bromide (Bromo Methane) | CH3Br | A |

| Methyl Cellosolve | CH3OCH2 CH2OH | A |

| Methyl Chloride | CH3CI | A |

| Methyl Isobutyl Ketone (Hexone) | CH3COCH2CH (CH3)2 | A 70°F |

| Methyl Isopropyl Ketone | CH3COCH(CH3)2 | A 70°F |

| Methyl Methacrylate | CH2C(CH3)CO2CH3 | A 70°F |

| Methylene Bromide | CH2Br2 | A |

| Methylene Chloride | CH2CI2 | B 100°F |

| Milk | A | |

| Mineral Oil (Petroleum) | Hydrocarbons | A |

| Mixed Acids (Sulfuric & Nitric) | H2SO4, HNO3 | A |

| Molasses | A | |

| Monochlorobenzene | C6H5CI | A 100°F |

| N,N-Dimethyl Formamide (DMF) | HCON(CH3)2 | A 120°F |

| N,N-Dimethylaniline | C6H5N(CH3)2 | A |

| Naphtha (Petroleum Spirits) (Thinner) | Petroleum fractions | A |

| Naphthalene (Tar Camphor) | C10H8 | A |

| n-Hexane | C6H14 | A |

| Nickel Acetate | Ni(CH3CO2)2 | A |

| Nickel Chloride | NiCI2 | A |

| Nickel Nitrate | Ni(NO3)2&6H2O | A |

| Nickel Sulfate | NiSO4 | A |

| Nitric Acid (Conc.) | HNO3 | A 120°F |

| Nitric Acid _ 10% | HNO3 | A |

| Nitric Acid _ 25% | HNO3 | A |

| Nitric Acid _ 35% | HNO3 | A |

| Nitric Acid _ 50% | HNO3 | A |

| Nitric Acid _ 70% | HNO3 | A |

| Nitrobenzene | C6H5NO2 | A 70°F |

| Nitroethane | C2H5NO2 | A 70°F |

| Nitromethane | CH3NO2 | A 120°F |

| n-Octane | C8H18 | A |

| n-Propyl Acetate | CH3COO(CH2)2CH3 | A |

| o-Chlorophenol | C6H5CIO | A |

| o-Dichlorobenzene | C6H4CI2 | A 150°F |

| Oleic Acid (Red Oil) | C18H34O2 | A |

| Olive Oil | Mixed glycerides of acids | A |

| Oxalic Acid | (COOH)2 | A 120°F |

| Ozone | O3 | A |

| Palmitic Acid | CH3(CH2)14 COOH | A |

| Peanut Oil | Glycerides of fatty acids | A |

| Perchloric Acid | HCIO4 | A |

| Perchloroethylene (Tetrachloroethylene) | C2CI4 | A |

| Petroleum (Crude Oil) (Sour) | Hydrocarbons | A |

| Phenol (Carbolic Acid) | C6H5OH | A 100°F |

| Phenyl Hydrazine | C6H5NHNH2 | A 120°F |

| Phosphoric Acid (Conc.) | H3PO4 | A |

| Phosphoric Acid _ 10% | H3PO4 | A |

| Phosphoric Acid _ 20% | H3PO4 | A |

| Phosphoric Acid _ 50% | H3PO4 | A |

| Phosphorus Trichloride | PCI3 | A |

| Photographic Developer | A | |

| Picric Acid (Carbazotic Acid) | (NO2)3 C6H2OH | A |

| Plating Solution _ Cadmium | B | |

| Polyvinyl Acetate Emulsion | PVac + H2O | A |

| Potassium Acetate | CH3CO2K | A |

| Potassium Bicarbonate | KHCO3 | A |

| Potassium Bisulfate | KHSO4 | A |

| Potassium Bromide | KBr | A |

| Potassium Carbonate (Potash) | K2CO3 | A |

| Potassium Chlorate | KCIO3 | A |

| Potassium Chloride | KCI | A |

| Potassium Chromate | K2CrO4 | A |

| Potassium Copper Cyanide | K3[Cu(CN)4] | A |

| Potassium Cyanide | KCN | A |

| Potassium Dichromate | K2Cr2O7 | A |

| Potassium Hydroxide (Caustic Potash) (Lye) | KOH | A 150°F |

| Potassium Iodide | KI | A |

| Potassium Nitrate (Saltpeter) | KNO3 | A |

| Potassium Permanganate (Purple Salt) | KMnO4 | A |

| Potassium Sulfate | K2SO4 | A |

| Potassium Sulfide | K2S | A |

| Potassium Sulfite | K2SO32H2O | A |

| Propane (LPG) | C3H8 | A |

| Propyl (Propanol) | C2H5CH2OH | A 120°F |

| Propyl Alcohol (1-Propanol) | CH3CH2CH2OH | A |

| Propylene Glycol (Methyl Glycol) | C3H6(OH)2 | A |

| Pyroligneous Acid (Wood Vinegar) | A | |

| Sal Ammoniac (Ammonium Chloride) | NH4CI | A |

| Salicylic Acid | A | |

| Salt Water (Brine) | NaCl/H2O | A |

| Sea Water (Brine) | A | |

| Sewage | A | |

| Silicone Oils (Versilube etc.) | [(CH3)2SiO2)]n | A |

| Silver Cyanide | AgCN | A |

| Silver Nitrate | AgNO3 | A |

| Soap Solutions | Salt of fatty acid in H2O | A |

| Sodium Acetate | CH3COONa | A |

| Sodium Aluminate | Na2Al2O4 | A |

| Sodium Bicarbonate (Baking Soda) | NaHCO3 | A |

| Sodium Bisulfite (Cream of Tartar) | NaHSO3 | A |

| Sodium Bisulfite (Niter Cake) | NaHSO4 | A |

| Sodium Borate | Na2B4O7 | A |

| Sodium Bromide | NaBr | A |

| Sodium Chlorate | NaCIO3 | A |

| Sodium Chloride (Table Salt) | NaCI | A |

| Sodium Chromate | Na2CrO4 | A |

| Sodium Cyanide | NaCN | A |

| Sodium Dichromate (Sodium Bichromate) | Na2Cr2O7&2H2O | A |

| Sodium Fluoride | NaF | A |

| Sodium Hydroxide (Caustic Soda) (Lye) | NaOH | A |

| Sodium Hypochlorite | NaCIO | A |

| Sodium Metasilicate | Na2SiO3 | A |

| Sodium Nitrate (Chile Saltpeter) | NaNO3 | A |

| Sodium Nitrite | NaNO2 | A |

| Sodium Perborate | NaBO3 | A |

| Sodium Peroxide (Sodium Dioxide) | Na2O2 | A |

| Sodium Phosphate (Tribasic) (TSP) | Na3PO4 | A |

| Sodium Silicates (Water Glass) | Na2O SiO2 | A |

| Sodium Sulfate (Salt Cake) (Thenardite) | Na2SO4 | A |

| Sodium Sulfide (Pentahydrate) | Na2S &5H2O | A |

| Sodium Sulfite | Na2SO3 | A |

| Sodium Tetraborate | Na2B4O7 &1&0H2O | A |

| Sodium Thiosulfate (Antichlor) | Na2S2O3 | A |

| Stannic Chloride (Tin Chloride) | SnCI4 | A |

| Stannous Chloride (Tin Chloride) | SnCI2 | A |

| Stearic Acid | CH3(CH2)16CO2H | A |

| Styrene (Vinylbenzene) | C6H5CHCH2 | A |

| Sulfur | S | A |

| Sulfur Chloride | S2CI2 | A |

| Sulfur Dioxide | SO2 | A |

| Sulfuric Acid (Conc.) | H2SO4 | A 120°F |

| Sulfuric Acid 10% | H2SO4 | A |

| Sulfuric Acid 25% | H2SO4 | A 150°F |

| Sulfuric Acid 50% | H2SO4 | A 150°F |

| Sulfuric Acid 60% | H2SO4 | A 150°F |

| Sulfuric Acid 75% | H2SO4 | A 150°F |

| Sulfuric Acid 95% | H2SO4 | A 120°F |

| Sulfurous Acid | H2SO3 | A |

| Tall Oil (Liquid Rosin) | Rosin acids | A |

| Tannic Acid | C76H52O46 | A |

| Tartaric Acid | C4H6O6 | A |

| Terpineol (Terpilenol) | C10H18O | B 120°F |

| Tetrachloroethane (Acetylene Tetrachloride) | (CI2HC)2 | A |

| Tetrachloroethylene | CI2C = CCI2 | A |

| Tetraethyl Lead | Pb(C2H5)4 | A |

| Tetrahydrofuran (THF) | C4H8O | B 70°F |

| Titanium Tetrachloride | TiCI4 | B |

| Toluene (Toluol) | C7H8 | A |

| Tomato Pulp & Juice | A | |

| Triallyl Phosphate | P(OC3H5)3 | A |

| Tributyl Phosphate (TBP) | (C4H9)3PO4 | A 100°F |

| Trichloroacetic Acid (TCA) | CCI3COOH | B |

| Trichloroethane | C2H3CI3 | A |

| Trichloroethylene (Ex-Tri) (Hi-Tri) | C2HCI3 | A |

| Triethyl Amine | (CH3CH2)3N | A 120°F |

| Turpentine | C10H16 | A |

| Unsymmetrical Dimethyl Hydrazine (UDMN) | H2NN(CH3)2 | A |

| Urea (Carbamide) | CO(NH2)2 | A |

| Urine | A | |

| Varnish (Oil, gum resins, oil of turpentine) | A | |

| Vinegar | Dilute acetic acid | A |

| Vinyl Acetate | CH3COOCHCH2 | A |

| Vinyl Chloride (Chloroethylene) | CH2CHCI | B |

| Water, Distilled (Also Deionized) | H2O | A |

| Water, Fresh | H2O | A |

| Whiskey | Ethanol, esters, acids | A |

| White Sulfate Liquor | A | |

| Wines | A | |

| Xylene (Xylol) | C6H4(CH3)2 | A |

| Zinc Acetate | Zn(C2H3O2)2 | A |

| Zinc Chloride | ZnCI2 | A |

| Zinc Sulfate | ZnSO4 | A |

| HCCIF2 | A |

Accessories

- Base Frame

- Coupling

- Coupling Guard

- Foundation bolt

- Strainer

Related products

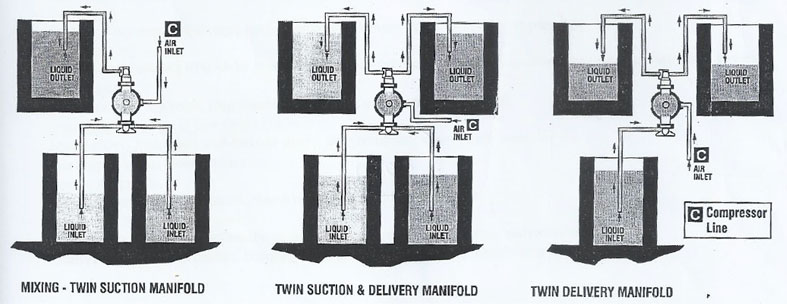

AODD Pumps – Air Operated Double Diaphragm Pumps Manufacturer

Advantages of Moniba AODD Pumps

- easy installation

- screwed chambers for safe operation

- rugged, cast feed mounting holes keep your pump from vibrating

- available as cover-mounted, pail-mounted or wall-mounted units

- immersible in most situations

- easy to adapt

- a large scale of material options for fl uid versatility with extended pump life

- air powered convenience for use in a variety of installations with no electrical hazard

- performs on-demand in remote locations

- extremely portable for multi-location use

- pumps move a wide variety of coatings, solvents, viscosity sealants, adhesives, inks, acids and more

- easy to maintain

- seal-less, leakproof design prevents fl uid waste and mess

- even in wet air, the stainless steel diaphragm rod air motor is designed for long life and corrosion resistance

- easy to operate

- pumps reduce or eliminate manual fi lling and transport

- multiple dispense points throughout your plant can easily be served.

- can run dry without pump damage

- no air lubrication necessary.

| Temperature | Max 90oC |

| Solid Size | Max 10 MM |

| Solid % | Max 50% |

| Viscosity | 15000 CP |

| Self Priming | 6mtr of Water column |

Range

| Model | Inlet air connection in inches | Inlet in inch | Outlet in inch | Max flow in LPM | Max Solid Size in MM | Material of casing |

| AIRON15 | 1/4" | 1/2 | 1/2 | 33 | 2.5 | PP,SS,PVDF,AL |

| AIRON25 | 1/4" | 1 | 1 | 60 | 3.4 | PP,SS,AL,PVDF |

| AIRON40 | 1/2" | 1.5 | 1.5 | 140 | 5.0 | PP,SS,AL |

| AIRON50 | 3/4" | 2 | 2 | 300 | 6.5 | PP,SS,AL |

| AIRON80 | 1" | 3 | 3 | 440 | 10.0 | ALUMINUM |

Air Operated Double Diaphragm Pumps Manufacturer

Moniba Pumps is known to be one of the finest Air Operated Double Diaphragm Pumps Manufacturer in India. Our Air Operated Double Diaphragm Pumps can be used for difficult-to-pump applications in Petrochemical Plants, Oil and Gas, Pharmaceutical, Food Processing, Mining, Marine and various other applications. Air Operated Double Diaphragm Pump are easy to maintain, provide reliable performance, and eliminate downtime to give you the best performance. Moniba Pumps has been a leading AODD Pumps Manufacturer in India since a long time in the industry. We supply engineered solutions across companies that operate on the basis of Pumps.

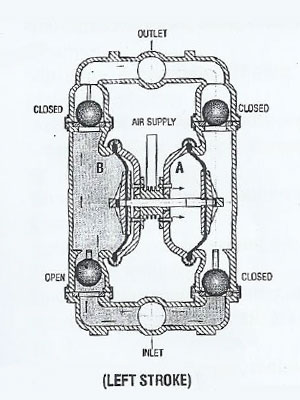

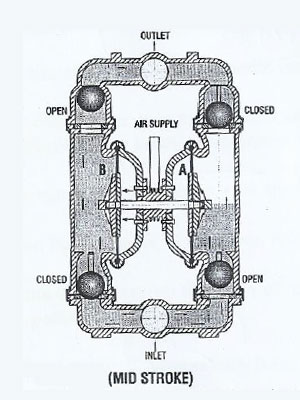

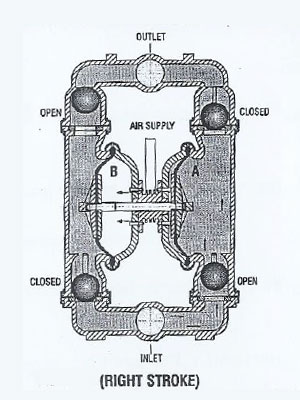

How the Pump Works

LEFT STROKE

The air valve directs pressurized air to the back side of diaphragm A. The compressed air is applied directly to the liquid column separated by elastomeric diaphragms. The diaphragm acts as a separation membrane between the compressed air and liquid, balancing the load and removing mechanical stress from the diaphragm. The compressed air moves the diaphragm away from the center block of the pump. The opposite diaphragm is pulled in by the shaft connected to the pressurized diaphragm. Diaphragm B is on its suction stroke; air behind the diaphragm has been forced out to the atmosphere through the exhaust port of the pump. The movement of diaphragm B toward the center block of the pump creates a vacuum within chamber B. Atmospheric pressure forces fluid into the inlet manifold forcing the inlet valve ball off its seat. Liquid is free to move past the inlet valve ball and fill the liquid chamber (see shaded area).

Mid stroke

When the pressurised diaphragm, diaphragm A, reaches the limit of its discharge stroke, the air valve redirects pressurised air to the back side of diaphragm B. The pressurised air forces diaphragm B away from the center block while pulling diaphragm A to the center block. Diaphragm B is now on its discharge stroke. Diaphragm B forces the inlet valve ball onto its seat due to the hydraulic forces developed in the liquid chamber and manifold of the pump. These same hydraulic forces lift the discharge valve ball off its seat, while the opposite discharge valve ball is forced onto its seat, forcing fluid to flow through the pump discharge. The movement of diaphragm A toward the center block of the pump creates a vacuum within liquid chamber A. Atmospheric pressure forces fluid into the inlet manifold of the pump. The inlet valve ball is forced off its seat allowing the fluid being pumped to fill the liquid chamber.

Right stroke

At completion of the stroke, the air valve again redirects air to the back side of diaphragm A, which starts diaphragm B on its exhaust stroke. As the pump reaches its original starting point, each diaphragm has gone through one exhaust and one discharge stroke. This constitutes one complete pumping cycle. The pump may take several cycles to completely prime depending on the conditions of the application.

Moniba Pumps, being the Air Operated Double Diaphragm Pumps Manufacturer in India, procure every step of processing in the most efficient manner and thus, we maintain our processing standards with the best in class techniques and operations that result in flawless and rust-free end products with long industrial life.

We are also a Air Operated Double Diaphragm Pumps Exporter in India in India. We manufacture superior quality of AODD Pumps, adhering to specific qualified standards of manufacturing guided by the governing bodies and export the same overseas.

Industries & Application

Among the lot of the most appreciated Air Operated Double Diaphragm Pumps Manufacturer in India in the industry, we have achieved great heights in this field. Some of the Industrial uses of pumps produced by the best AODD Pumps Manufacturer in India are as follows-

Automotive Industry: Grinding emulsion, oil, coolant, hydraulic fluid, sulfuric, automotive primer, soluble oil, varnish disposal, Varnish additives, degreasing baths, cutting oil, water and glycol mixture, paint Aviation: Aircraft fuelling and drainage, satellite refueling, solid rocket propellant, missile silos Beverage Industry: Yeast, diatomaceous earth slurry, hot pulp, liquid hops, sugar syrup, concentrates, Gas-liquid mixtures, wine, fruit pulp, fruit juice, corn syrup Ceramics: Slip, glaze, enamel slip, effluent, clay, clay slurry, lime slurry, kaolin slurry Chemical Industry: Acids, alkalies, solvents, suspensions, dispersions, magnesium hydroxide, varnishes, sump water, resins, Latex, adhesives, effluent sludge, stabilizers, filter press, electrolytes Construction Industry: Sump and pit drainage, cement slurry, ceramic tile adhesive, rock slurry, ceiling coating paints, texture spray Cosmetics: Lotions, creams, shampoos, emulsions, hand creams, surfactants, hair permanents, soaps Electronics Industry: Solvents, electroplating baths, ultrapure liquids, carrier fluids for ultrasonic washing, sulfuric, nitric and acid Wastes, etching acids, MEK, acetone, polishing compounds Food: Brine, chocolate, vinegar, molasses, dog food, vegetable oil, soy bean oil, honey, cat food, HCL, animal blood Furniture Industry: Adhesives, varnishes, dispersions, solvents, stains, Elmer’s Glue, white good glue, solvents, glue (5-6000 cps) epoxy, starch adhesives, spray packages Mining: Sump gallery drainage, water drainage, coal sludge and rock slurry, cement slurry, grounding mortar, oil transfer, Explosive slurry, adhesive, lube oil, foaming Paints & Coatings: Resins, solvents, acrylic, wood preservative stain, concrete paints, varnishes, titanium dioxide slurry, primers, Stains, dispersions, varnish cleaning baths, alkalyd resin Pharmaceutical Industry: Vegetables extracts, tablet pastes, ointments, alcohols, filtering aids, ultra filtration,Blood plasma, waste solvents, sump waste Plating: Anodic sludge, electroplating baths, varnishes, enamels, solvents, cleaning baths, filtering Pulp/Paper/Packaging: Latex, adhesives, paints, resins, printing inks, dispersions, TiO2 slurry, Kaolin clay, hydrogen peroxide Refineries: Tank roof drainage, oil sludge, tank cleaning, tank moat drainage, portable pumping Road Tanker Trucks: Loading and draining of tank by means of pump on vehicle, tank vehicle washing facilities, acid spraying, foaming Shipbuilding: Tank and bilge drainage, ship cleaning, stripping, oil skimming, seawater Smelters, Foundries & Dye Casting: Metal slurry, hydroxide and carbide slurry, dust scrubbing slurry, back wash for Flushing of cores, mold release Textile & Carpet: Dyeing chemical, scotch guard, starch and sizing, resins, dyes, latex Water and Sewage Treatment: Milk of lime, thin slurry, effluents, chemicals, charging of filter presses, polymer, waste water Utility: Contaminated liquids, charging of scrubbers, milk of lime, transformer oil, resins

Ceramics

The items cover in the ceramics industry include Slip and glaze, filter presses, abrasive fluids,and sanitary products

Chemical & Petrochemical

The items over in the chemical and petrochemical Industry include acids, alcohols, hydrocarbons, solvents,and organics

Coatings: PAINTS & INKS

The items cover in the coatings industry Include paints, inks, dyes, resins, and Adhesives, solvents

Food & Beverage

The items we cover in the food and beverage industry include beverages, dairy products , purees, juices, and preserves

Wastewater

The items cover in the wastewater treatment Industry includes chemical waste and general waste.

PAINTS & INK DIPENSING MACHINE

ACCESSORIES

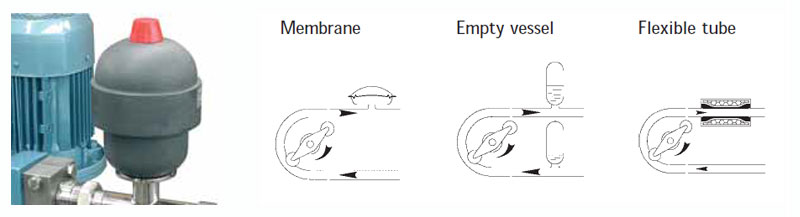

PULSATION DAMPENERS FOR REDUCING PULSATION IN PERISTALTIC PUMPS

As fluid enters the head of a peristaltic pump, it becomes trapped between two rollers. This "pillow" of fluid is followed by a void, where the tubing is occluded by the rollers. Alternating pillows and voids cause fluid flow to be pulsated, rather than smooth and continuous Figure. If pulsation is undesirable, using a pump head with adjustable occlusion can lessen the pulsation by a quarter. Reducing occlusion decreases the degree of pulsation because there is less distinction between fluid pillows. Some applications, however, are more sensitive to the pulsating flow produced by a peristaltic pump. These applications may require smoothing the flow by more than 25%. In these cases, four other methods may be considered for reducing pulsation further: using pump heads with offset occlusion and multiple-roller design; mounting multiple pump heads at an offset; using a pulse dampener; and changing the configuration of the discharge tubing.

Pulsation Dampeners

Pulsation DampenersA pulse dampener can be inserted into the discharge line to reduce pulsation. As the pulsating flow enters the dampener vessel, the air pocket trapped above the fluid absorbs up to 90% of the pulsation. A smoother flow leaves the vessel. For all tubing sizes, a pulse dampener can easily be fabricated using a retaining vessel and appropriately sized fittings, The outlet of the dampener should be at the same height as, or lower than, the inlet in order to reduce dead volume. Both inlet and outlet should be located near the bottom of the vessel to trap air in the top of the vessel. Changing the configuration of the channel through which the tubing flows can also reduce pulsation. Extending the length of the discharge tubing several times and selecting a softer tubing material, such as silicone, can reduce pulsation by as much as 60%. Softer tubing helps absorb fluid pulsation, and a longer discharge line increases friction. The increase in friction raises back pressure, which compresses the pulses together, thereby reducing pulsation.

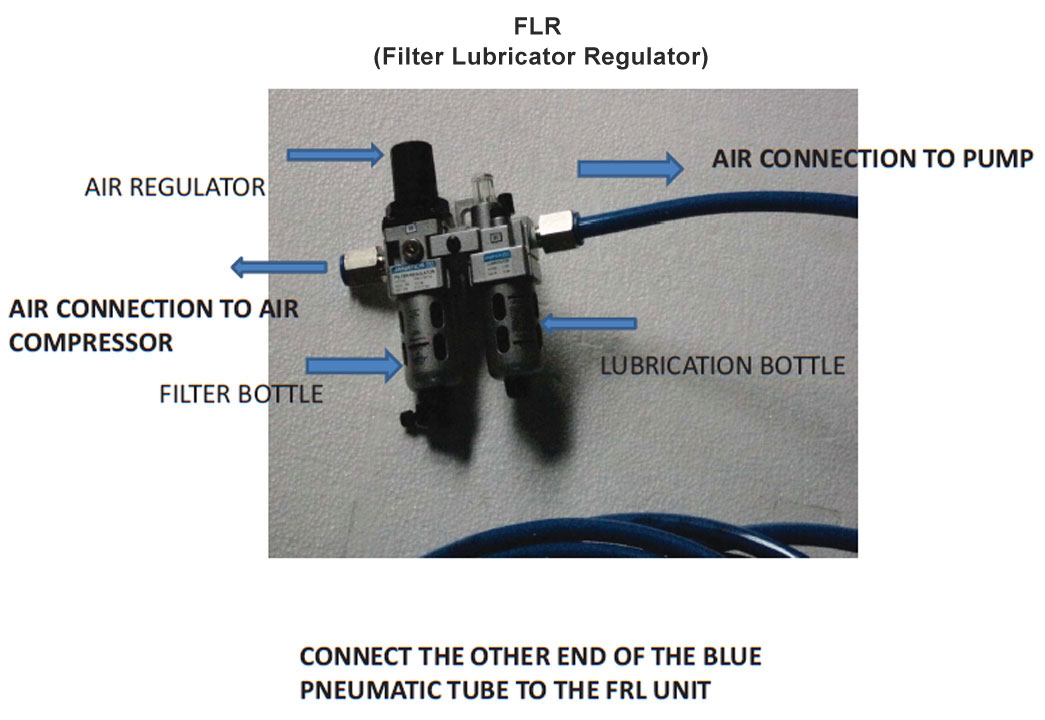

FLR UNIT(FILTER LUBRICATOR REGULATOR)

Canned Motor Pumps, Liquid Ammonia Pumps

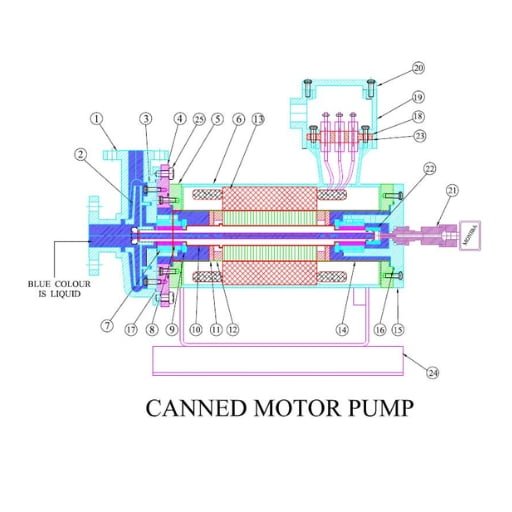

About Sealless Canned Motor Pumps

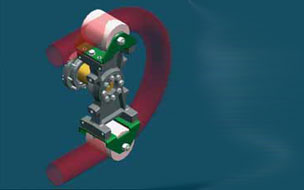

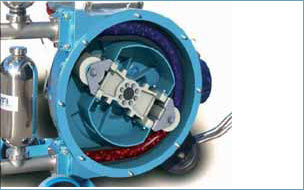

- Canned Motor Pump is a combination of a centrifugal pump and an induction motor presented as an integral unit. In the canned motor Configuration the motor is mounted directly on the same shaft as the impeller.

- Canned pumps are of simple design and construction, having very few parts and only two rotating parts-rotor and the impeller.

- Secondary sealing is restricted to a couple of static gasket, which are again well confined.

- Canned pumps do not required any external lubrication.

- Canned pump is seal less and auxiliary support arrangements for cooling seals are not required.

- Bush Bearings made out of carbon graphite and silicon carbide are the only parts that come up for replacement and the bearing have a very long life since there is no load on bearings, because of automatic thrust balancing, inherent in the design.

- Canned pumps runs with negligible vibrations (<10 microns) and thereby wear and tear is greatly diminished.

- Maintenance and operational cost are negligible compared to conventional pump.

- CANNED PUMPS NEVER LEAK – on continuous or intermittent pumping or even in case of pump failure.

- MONIBA PUMPS are certified FLAME PROOF/EXPLOSION PROOF (EEx-d IIB T6 (Ex) ds.).

- Conform to AP1685, 1st edition for petroleum application.

- Approved by leading consultancy in India.

- Catering to wide range of service & duty conditions.

- Available in all possible verity of construction.

FEATURES AND BENEFITS:-

Features

- No mechanical seal or its API systems

- No coupling

- No external lubrication

- Vacuum light

- Hermetically sealed with Secondary fluid Containment.

- No rigid foundation.

- Compact- saves 40%space.

- Flame proof and explosion Proof.

Benefits

- Zero emission

- No alignment

- No product loss

- Longest MTBF

- Low vibration and noise level

- Negligible maintenance

- Lowest cost of operation

Accessories

| SR.NO | PART NAME | QTY. |

| 1 | CASING | 01 |

| 2 | IMPELLER | 01 |

| 3 | FRONT BEARING HOUSING | 01 |

| 4 | ADAPTER | 01 |

| 5 | END BELL PLATE | 02 |

| 6 | STATOR BODY | 01 |

| 7 | BEARING | 02 |

| 8 | SLEEVE | 02 |

| 9 | THRUST WASHER | 02 |

| 10 | ROTOR SHAFT | 01 |

| 11 | CANNED ROTATOR | 01 |

| 12 | CANNED STATOR | 01 |

| 13 | STATOR WITH WINDING | 01 |

| 14 | SUPPORT SLEEVE | 02 |

| 15 | REAR BEARING HOUSING | 01 |

| 16 | O RING | 03 |

| 17 | GASKET | 01 |

| 18 | TERMINAL PLATE | 01 |

| 19 | TERMINAL BOX | 01 |

| 20 | TERMINAL COVER | 01 |

| 21 | BEARING MONITOR | 01 |

| 22 | WEAR NUT | 01 |

| 23 | TERMINAL PLATE GASKET | 02 |

| 24 | BASE FRAME | 01 |

| 25 | FASTENERS | - |

Hose Pump Moniba

Industrial Hose Pump Manufacturers

Moniba Pumps is one of the leading Industrial Hose Pump Manufacturers in India and Suppliers in India. The Industrial Hose Pump manufactured by us is a two roller peristaltic pump which are specially designed to handle corrosive slurries, vicious fluids and other aggresive chemicals which are usually difficult to pump with any other type of positive displacement.

The basic principle of the Peristaltic Hose Pump traces back to human “peristalsis” a term referring to the alternating contraction and relaxation of muscles around a tube to force the contents through it. An elastomeric tube is squeezed along a length by rollers that push the fluid contained within. The tube’s restitution after squeezing produces a vacuum that draws fluid continuously into the tube.

This creates a gentle pumping action that doesn’t cause any damage to the product. Contaminations are avoided because the fluid is contained within the tube (one contact part with product).The pump employs a rotor with rollers mounted on it that continually compress and occlude some portion of the tube. This action moves the fluid through the tube with a constant rate of displacement for each revolution of the rotor, enabling a precise measurement of the volume of fluid pumped through the tube.

Being one of the most prominent Industrial Hose Pump Manufacturers in India, we, at Moniba Pumps, adhere to the best practices while manufacturing the products. The offered products and services are completely error-free so the end user experiences maximum satisfaction. The Positive displacement pumps create a pumping action by alternatively compressing & relaxing the hose between pump housing and compressing rollers. This positive displacement then generates one of the finest quality of pumps as the corrosion level is minimised to the least mark, thereby increasing the effective and smooth functioning of the product. Reliability and Durability of the pumps manufactured is restored and maintained for a long industrial life. Apart from this, timely checks and tests are performed to check the performance of the product. We are thus proud to be one of the leading and eminent Industrial Hose Pump Manufacturers in India in the industry.

Industrial Pumps or as we say Peristaltic Hose Pumps and Tube pumps are the ideal solution for pumping liquids and dosing chemicals. Peristaltic Hose Pumps are used in many industries including: water and wastewater, mining, food & beverage, chemical, pharmaceuticals, printing and packaging. We are thus, considered one of the finest Peristaltic Hose Pumps Manufacturer in India in Mumbai, India.

Backed by our team of professionals, we have emerged as a successful Industrial Hose Pump Exporter. The Industrial Hose Pumps we make available are designed for pumping foam concrete and liquids with solid particles. We hold the expertise of delivering bulk orders of the Hose Pumps within the promised time frame. The entire range of the Hose Pumps is reasonably priced by us.

If ouy are searching for any information related to Industrial Hose Pump Manufacturers or Production, then you can switch to Moniba Pumps. We will provide you all the neccessary information including pricing. We are also Polypropylene Pump Manufacturers, recognised around the boundaries and also across the globe to some extent.

Connect with us NOW!

The MONIBA ANAND PUMP

The MONIBA ANAND PUMPMoniba Pumps have proved to be one of the notable Industrial Hose Pump Manufacturers in India. Apart from the quality assurance, some other benefits offered by the pumps manufactured at Moniba Anand are as follows :

- It eliminates the requirement for adding a lubrication fluid inside the pump housing, because there is no friction on the surface of the tube therefore giving a longer tube life.

- They can transfer food products with no con tamination hazards, as the pump housing is lubrication free.

- With no lubrication fluid required, hose replacement is greatly simplified and cheaper without having to drain and dispose of a messy and possibly contaminated oil or glycerine solution.

Industries & Application

Abrasive Products The Moniba Anand Pump is excellent on abrasive slurries where it has had much more success than other pumps. The Moniba Anand Pump parts stay out of the product zone and the hose is the only one thing that is in contact with the product, this keeping abrasive wear to a minimum. Products that crystallize are also well pumped by the Moniba Anand Pump. There are no valves or glands so the eventual build up of crystals could not clog the pump. Corrosive Products With corrosive fluids the hose selection is of paramount importance to the longevity of the pump. With the correct hose selection and no other contact mechanical parts in the product, this ensures a long pump life. Fluids With Solid Parts Or Sensitive Products A problematic product for many pump types is fluids with solid particles such as waste water with gravel, pieces of wood, concrete or foods, where as the peristaltic pump due to free tube-passage can easily transfer it without any product or pump damage. The Moniba Anand Pump is also a good choice for transferring shear-sensitive fluids or foamy products, the non emulsifying action minimises damage to the product or its consistency. Viscous Products The Moniba Anand Pump gives a strong self-priming suction which can draw almost full vacuum, producing the pull necessary to draw viscous materials such as honey, grout, resins or waste sludge, which is almost impossible for many other pump types. Environmental Applications There are two main environmental applications for the Moniba anand pump: - Chemical metering - Sludge transfer

- Chemical metering: The most common is for Sodium Hypochlorite, Sodium Bisulfite, Ferric Chloride and some polymers, as well as lime slurry and carbon slurry. Above all with sodium hypochlorite that emits off gas, the Moniba anand pump doesn’t loose efficiency due to pockets of air, pumping together both liquid and gas

- Sludge: The Moniba Anand Pump can handle many different kinds of sludge depending upon the level of treatment in a plant. It can feed and transfer thickened sludge, waste activated sludge, return activated sludge and corrosive sludge.

Application

- ceramic for high density ceramic slip tranfer

- chemical industries-transfer of highly corrosive/ abrasive chemical slurry

- Water and waste treatment-dosing of water treatment chemicals like powdered activated Carbon, lime, alum, hypochlorite

- food and beverage-transfer of shear sensitive substances like milk, yeats, molases, chocolate, fruits

- metallurgy-treatment and leaching of metal slurry

- mining-transfer of high density mineral sludge, thickner underflow, metal tailings flocculant

- Construction-concrete transfer, cellular light weight cement transfer

- Paints and Pigments-acidic pigment slurry for filter press, high viscosity paint sludge

- paper pulp-black/green/ white liquor transfer, treated paper plup transfer,hcl/hypo dosing.

Advantages

- No seals

- No valves

- Self priming

- Only tube to replace

- Reverse flow by reversing motor

- No contact between product and mechanical parts

- Can run dry without damage

- Able to pump products with solid parts inside

- Suitable for CIP applications

- Fragile or sensitive fluids

- Compound fluids

- Abrasive and corrosive fluids

- Non pollutable or pollutant fluids

Range

| Pump Model | MOTOR HP | Flow Range in LPH | Max Solid size in MM |

|---|---|---|---|

| MOPSF-3 | 0.5 | 0-200 | 6 |

| MOPSF-2 | 0.5 | 0-760 | 10 |

| MOPSF-1 | 0.5 to 1.5 | 0-3150 | 15 |

| Pump Model | MOTOR HP | Flow Range in LPH | Max Solid size in MM |

|---|---|---|---|

| MOMS-1 | 1 to 5 | 0-7680 | 24 |

| MOMS-2 | 2 to 7.5 | 0-17440 | 33 |

| MOMS-3 | 3 to 10 | 0-30800 | 40 |

Specifications

This parameters depend on size of pump| Temperature | Max 95oC |

| Solid Size | Max 40 MM |

| Solid % | Max 80% |

| Viscosity | 100000 CP |

| Use | low RPM Continues |

| Use | high RPM intermediate |

| Self Priming | 9mtr of Water column |

| Delivery Head | Up to 80 mtr |

Accessories and optionals

Connections

Flanges DIN; ANSI;

DIN 11851 Threaded , Clamp, Tri-clamp, RJT, SMS, BSP threaded

In: S.S. 316,

PVC,

Polypropylene,

Titanium

Variable Gear Speed

Ratio 1-5

Frequency Inverter

Ratio 1-10

Pulse Dampeners

The pulse dampeners are suggested in case of negative suction and pressure over 2 bar; they ensure a better pump working and a longer tube life.

Three types are available:

Feeder

The models of MS and SDF Serie can be equipped of feeder to feed products with solid parts or sensitive parts.

Leak detector

All MONIBA ANAND PUMP (optional for PSF Serie) are equipped of leak detector to provide early indication of hose failure. This is a float type sensor that is located at the lowest point of the pump housing.

Feeder

The models of MS and SDF Serie can be equipped of feeder to feed products with solid parts or sensitive parts.

Leak detector

All MONIBA ANAND PUMP (optional for PSF Serie) are equipped of leak detector to provide early indication of hose failure. This is a float type sensor that is located at the lowest point of the pump housing.

Vacuum system

This device helps the pump to suck viscous and thicky products.

Vacuum system

This device helps the pump to suck viscous and thicky products.

PP Pumps, Polypropylene Pump Manufacturers

Polypropylene Pump Manufacturers

Moniba Pumps is one of the established and developed Polypropylene Pump Manufacturers in India that offers an exceptional range of pumps for the cients. Polypropylene Pumps are extraordinarily planned for very destructive synthetic compounds in which metal pumps are not prescribed or in its cost is higher. The PP-arrangement pumps configuration are single piece shaped polypropylene volute packaging with semi-open impeller and packaging spread to guarantee a smooth running execution against erosion.

Moniba Anand Electricals Pvt. Ltd. has developed Non-mettalic Centrifugal Pumps to replace high cost mettalic Pumps, with the best hydraulic design, resulting in maximum efficiency. This has been achieved by extracting major components in injection moulding dies, whereby the finishing & the dimensions are consistent. To further prevent any leakage, a mechanical seal of Teflon below, is used in all our Non-mettalic Pumps.

Being one of the leading Polypropylene Pump Manufacturers we use high allumina fired sleeve that secures shaft to any erosion and scraped spot. The GFT or Sic Vs. Fired PTFE underneath Mechanical seal keeps the spillage from the pumps. The Cast Iron are heavily oil greased to provide greatest quality to pump. The pumps are additionally accessible in Mon-square form with minimal plan.

Moniba Pumps being distinguished Polypropylene Pump Manufacturers in India produce these pumps in variety of specifications to suffice the diverse requirements of these industries. Polypropylene is the most widely used plastic by us and is also usually known by it's chemical name, PP. Polypropylene Plastic is known for its wide ranging chemical resistance. Polypropylene Pumps are commonly used for chemicals such as Fresh Water, Salt Water, DI Water, Citric Acid, Fluosilicic Acid, Formaldehyde, Muratic Acid, Nitric Acid, Phosphoric Acid, Potassium Hydroxide, Potassium Permanganate, Sodium Hydroxide, Sulfuric Acid, and many more.

The pumps are also used in scrubbing of corrosive gases and as scrubber pump in various chemical industries, in pickling process in Steel Rolling Mills, Acid circulation in electro plating industries, decaling in boilers, heat exchangers etc. Our main aim is to accomplish most extreme level of clients and this is finished by offering Polypropylene Pumps according to the market request. Being the most astounded and recommended Polypropylene Pump Manufacturers in India is a title of which we are proud of and also a level that needs to be maintained. The whole scope of pumps offered by us is fabricated with the guide of most recent innovation and refined machines.

We guarantee that the pumps offered by us take into account the requirements of profluent treatment plants, water treatment plants, drugs and pharmaceuticals, manure plants and others. We make Polypropylene Pumps accessible to the clients at exceedingly aggressive costs. We are considered one of the finest PP Pump Manufacturers in India in the country and are also bound to become a successful and prominent Polypropylene Pump Exporter in India in the near future.

Advantages

- All wetted parts are offered in polypropylene having good resistance to erosion for slurry service.

- Impeller radial semi open robust construction injection molded with back vanes to minimize axial thrust for increased bearing life and with ss insert for easy removal

- Shaft sleeve is of ceramic, Hastelloy-B, Alloy 20, Monel, Titanium to suit various applications.

- Pump can be supplied with priming chamber for selfpriming application.

- Pumps are available with different mounting like monoblock, horizontal bare pump, vertical pump

- All non pp parts are coated with anti corrosive paints to protect from corrosive atmosphere

- Available with externally mounted mechanical Seal of ceramic/GFT, or silicon face with teflon as per application.

- External Cooling arrangement provided in pump for enhancement of mechanical Seal life

Range

| Series | Max flow in m3/hr | Max head in mtr |

| PPA | 18 | 25 |

| PPB | 38 | 31 |

| PPC | 50 | 51 |

| PPD | 400 | 100 |

| Temperature | Max 90oC |

| Power | Up to 25 hp |

| Solid % | Max 30% |

| Soft Solid Size | Max 3 MM |

Perforamance

| MONIBA ANAND ELECTRICALS PVT LTD | |||||||||||

| Sr No. | Model | Graph no. | Q= m3/hr & H=meter | Shut off head in meter | |||||||

| 1 | P-22-100H | PPN1 | Q | 0 | 1 | 2 | 3 | 4 | 5 | 6 | 14 |

| H | 14 | 13.5 | 13 | 12.5 | 12 | 10 | 7 | ||||

| 2 | P-44-120H | PPN2 | Q | 0 | 5 | 7 | 10 | 12 | 15 | 17 | 18 |

| H | 18 | 16 | 15.5 | 15 | 13 | 10 | 7 | ||||

| 3 | P-34-130H | PPN3 | Q | 0 | 5 | 7 | 10 | 12 | 15 | 18 | 25 |

| H | 25 | 22 | 20.5 | 18 | 16 | 14 | 11 | ||||

| 4 | P-44-150H | PPN4 | Q | 0 | 5 | 7 | 10 | 12 | 15 | 18 | 25 |

| H | 25 | 20 | 18 | 16.5 | 15 | 14 | 10 | ||||

| 5 | P-47-160H | PPN5 | Q | 0 | 5 | 10 | 15 | 20 | 25 | 32 | 33 |

| H | 33 | 31 | 30 | 27 | 23.5 | 20.5 | 17 | ||||

| 6 | P-44-190L | PPN6 | Q | 0 | 5 | 10 | 15 | 20 | 25 | 27 | 14 |

| H | 14 | 13 | 12.5 | 12 | 10.6 | 11 | 10 | ||||

| 7 | P-47-210L | PPN7 | Q | 0 | 7 | 12 | 17 | 23 | 28 | 34 | 15 |

| H | 15 | 13.6 | 12.5 | 11.6 | 11 | 10 | 7 | ||||

| 8 | P-57-210L | PPN8 | Q | 0 | 10 | 20 | 30 | 40 | 50 | 52 | 16 |

| H | 16 | 15 | 13.7 | 12 | 11 | 7.6 | 7 | ||||

| 9 | P-57-170H | PPN9 | Q | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 37 |

| H | 37 | 35 | 33 | 30 | 27 | 22 | 15.5 | ||||

| 10 | P-45-190H | PPN10 | Q | 0 | 5 | 10 | 20 | 30 | 40 | 44 | 50 |

| H | 50 | 47 | 45 | 41 | 37 | 30 | 24 | ||||

| 11 | P-55-220L | PPN11 | Q | 0 | 5 | 11 | 16 | 22 | 31 | 40 | 18 |

| H | 18 | 17 | 16 | 15.5 | 15 | 13 | 11 | ||||

| 12 | P-55-210H | PPN12 | Q | 0 | 10 | 20 | 30 | 40 | 50 | 60 | 61 |

| H | 61 | 60 | 58 | 55 | 51 | 48 | 42 | ||||

| 13 | P-57-185H | PPN13 | Q | 0 | 20 | 40 | 60 | 80 | 100 | 105 | 48 |

| H | 48 | 46 | 45 | 41 | 38 | 32 | 30 | ||||

| 14 | P-81-265L | PPN14 | Q | 0 | 20 | 40 | 60 | 80 | 100 | 110 | 25 |

| H | 25 | 22 | 20 | 18 | 15 | 10 | 6 | ||||

PP Chemical Compatibility Chart

| Chemical | Formula | Polypropylene |

| Acetamide (Acetic Acid Amide) | CH3CONH2 | A |

| Acetic Acid _ 20% | B | |

| Acetophenone (Phenyl Methyl Ketone) | C6H5COCH3 | A 70°F |

| Acrylonitrile (Vinyl Cyanide) | CH2=CHCN | B |

| Adipic Acid (1,4-Butanedicarboxylic Acid) | HOOC(CH2)4 (COOH ) | A |

| Alcohols | R-OH | A |

| Allyl Chloride (3-Chloropropene) | CH2=CHCH2CI | A 70°F |

| Alum (Aluminum Potassium Sulfate Dodecahydrate) | KAI(SO4)2 &1&2H2O | A |

| Aluminum Acetate (Burow's Solution) | A | |

| Aluminum Ammonium Sulfate (Alum) | AINH4(SO4)2 | A |

| Aluminum Chloride | AlCl3 | A |

| Aluminum Fluoride | AlF3 | A |

| Aluminum Hydroxide (Alumina Trihydrate) | AI(OH)3 | A |

| Aluminum Nitrate | Al(NO3)3 &9H2O | A |

| Aluminum Potassium Sulfate (Potash Alum) | KAl(SO4)2 | A |

| Aluminum Sulfate (Cake Alum) | Al2(SO4)3 | A |

| Amines | R-NH2 | B |

| Ammonia Anhydrous, Liquid | NH3 | A |

| Ammonium Bifluoride _ 10% | NH4HF2 | A |

| Ammonium Carbonate | (NH4)2CO3 | A |

| Ammonium Chloride (Sal Ammoniac) | NH4Cl | A |

| Ammonium Fluoride | NH4F | B |

| Ammonium Hydroxide (Aqua Ammonia) | NH4OH | A |

| Ammonium Metaphosphate | A | |

| Ammonium Nitrate | NH4NO3 | A |

| Ammonium Nitrite | NH4NO2 | A 70°F |

| Ammonium Persulfate | (NH4)2S2O8 | A |

| Ammonium Phosphate, Di-Basic | (NH4)2HPO4 | A |

| Ammonium Phosphate, Monobasic | (NH4)H2PO4 | A |

| Ammonium Phosphate, Tri-Basic | (NH4)3PO4&3H2O | A |

| Ammonium Sulfate | (NH4)2SO4 | A |

| Ammonium Sulfite | (NH4)2SO3H2O | A |

| Amyl (1-Pentanol) | C4H9CH2OH | B |

| Amyl Alcohol (Pentyl Alcohol) | CH3(CH2)4OH | A |

| Amyl Chloronaphthalene | A | |

| Aniline (Aniline Oil) (Amino Benzene) | C6H5NH2 | A |

| Antimony Trichloride | SbCI3 | A |

| Arsenic Acid | AsH3O4 | A |

| Asphalt | Hydrocarbons | A |

| Barium Carbonate | BaCO3 | A |

| Barium Chloride Dihydrate | BaCl2 &2H2O | A |

| Barium Hydroxide (Barium Hydrate) | Ba(OH)2 | A |

| Barium Nitrate | Ba(NO3)2 | A |

| Barium Sulfate (Blanc Fixe) | BaSO4 | A |

| Barium Sulfide | BaS | A |

| Beer | Water, carbonate | A 75°F |

| Beet Sugar Liquors (Sucrose) | A | |

| Benzyl (Phenylcarbinol) | C6H5CH2OH | A |

| Benzyl Alcohol | C6H5CH2OH | A |

| Borax (Sodium Borate) | B4Na2O7 | A |

| Boric Acid (Boracic Acid) | H3BO3 | A |

| Brine (Sodium Chloride) | Salt water | A |

| Buttermilk | Fats, water | A |

| Butyl (Butanol) | C3H7CH2OH | B |

| Butyl Alcohol (Butanol) | CH3(CH2)3OH | A |

| Butyric Acid | CH3(CH2)2CO2H | A |

| Calcium Bisulfite | Ca(HSO3)2 | A |

| Calcium Carbonate (Chalk) | CaCO3 | A |

| Calcium Chlorate | Ca(ClO3)2 | A |

| Calcium Chloride (Brine) | CaCl2 &6H2O | A |

| Calcium Hydroxide (Slaked Lime) | Ca(OH)2 | A |

| Calcium Hypochlorite 20% (Calcium Oxichloride) | Ca(CIO)2 | A |

| Calcium Nitrate | Ca(NO3)2 | A |

| Calcium Sulfate (Gypsum) | CaSO4 | A |

| Calcium Sulfide | CaS | A 120°F |

| Calgon | (NaPO3)6 | A |

| Cane Sugar Liquors | Sucrose, water | A |

| Carbon Dioxide (Carbonic Acid Gas) | CO2 | A |

| Carbon Monoxide | CO | A |

| Carbonated Beverages | CO2/H2O | A |

| Carbonic Acid (liquid) | H2CO3 | A |

| Catsup (Ketchup) | A | |

| Cellosolve (Glycol Ethers) | HOCH2CH2OR | A 100°F |

| Chlorinated Water | B | |

| Chloroacetic Acid (Monochloroacetic Acid) | CICH2COOH | A |

| Chocolate syrup | Corn syrup, water, sugar | A |

| Citric Acid | C6H8O7 H2O | B |

| Citric Oils | Citric acid esters | A |

| Clorox | B | |

| Cobalt Chloride | CoCI2&6H2O | A |

| Coffee | Fatty oils, acids, ellulose, water | A |

| Copper Chloride | CuCl2&2H2O | A |

| Copper Cyanide | CuCN | A |

| Copper Nitrate Hexahydrate | Cu(NO3)2&6H2O | A |

| Copper Sulfate (Blue Copperas) | CuSO4&5H2O | A |

| Corn Oil (Maize oil) | Glycerides of fatty acids | A |

| Cotton Seed Oil | A | |

| Cream | A | |

| Cyclohexanol | C6H11OH | B |

| Decane | CH3(CH2)8CH3 | A 70°F |

| Denatured Alcohol | Ethanol and denaturant | A |

| Detergent Solutions | A | |

| Dextrose | C6H12O6 | A |

| Diesel Oil (Fuel ASTM #2) | Hydrocarbons | B |

| Diethanol Amine | (HOCH2CH2)2NH | A |

| Diethyl Amine | (CH3CH2)2NH | A |

| Diethyl Sebecate | C14H26O4 | A 120°F |

| Diethylene Glycol (DEG) | HOCH2CH2OCH2CH2OH | A |

| Diisobutylene | [HC=C(CH3)2]2 | A |

| Dipropylene Glycol | (C3H6OH)2O | A |

| Epichlorohydrin | C3H5CIO | A |

| Epsom Salts (Magnesium Sulfate) | MgSO4 &7H2O | A |

| Ethyl (Ethanol) | CH3CH2OH | A 100°F |

| Ethyl Acrylate | CH2CHCO2CH2CH3 | B |

| Ethyl Alcohol (Ethanol) | CH3CH2OH | A 100°F |

| Ethyl Benzoate | C6H5CO2CH2CH3 | B |

| Ethyl Butyrate | CH3CH2CH2 CO2C2H5 | B |

| Ethylene Diamine | (CH2)2(NH2)2 | A |

| Ethylene Glycol (Ethylene Alcohol, Glycol) | (CH2OH)2 | A 120°F |

| Fatty Acids | CnH2n+1COOH | B |

| Ferric Chloride | FeCI3 | A |

| Ferric Nitrate | Fe(NO3)3 | A |

| Ferric Sulfate | Fe2(SO4)3 | A |

| Ferrous Chloride | FeCI2 | A |

| Ferrous Sulfate | FeSO4 | A |

| Fluoboric Acid | HBF4 | A |

| Fluosilicic Acid (Sand Acid) | H2SiF6 | A |

| Formaldehyde (Formalin) | HCHO | A |

| Formic Acid | HCOOH | A 70°F |

| Freon 11 (Trichlorofluoromethane) | CCI3F | B |

| Fruit Juices | Water, sucrose | A |

| Gallic Acid | C6H(OH)3 COOH | A 70°F |

| Gelatin | Water soluble proteins | A |

| Glucose (Corn Syrup) | C6H12O6 | A |

| Glue | A | |

| Glycerol (Glycerine) | C3H8O3 | A |

| Glycolic Acid | HOCH2COOH | A |

| Glycols | A | |

| Grape Juice | Water, sucrose | A |

| Green Sulfate Liquor | A | |

| Heptanal | CH3(CH2)5CHO | A |

| Hexyl (1-Hexanol) | C5H11CH2OH | A 70°F |

| Honey | A | |

| Hydrobromic Acid | HBr | B |

| Hydrochloric Acid 10% (Muratic) | HCI | A |

| Hydrochloric Acid 20% (Muratic) | HCI | A |

| Hydrochloric Acid 30% (Conc.) | HCI | B |

| Hydrocyanic Acid (Formonitrile) | HCN | A |

| Hydrogen Fluoride _ Anhydrous | HF | A |

| Hydrogen Peroxide _ 10% | H2O2 | A |

| Hydrogen Peroxide _ 3% | H2O2 | A |

| Hydrogen Peroxide _ 30% | H2O2 | A |

| Hydrogen Sulfide (Wet) | H2S | A |

| Hypochlorous Acid | HCIO | A |

| Iodine | I2 | A |

| Isobutyl Alcohol (Isobutanol) | (CH3)2 CHCH2OH | A |

| Isooctane (Trimethylpentane) | C8H18 | A |

| Isopropyl (2-Propanol) | H3CCH(OH)CH3 | A |

| Isopropyl Acetate | CH3COOCH(CH3)2 | B |

| Isopropyl Alcohol (Isopropanol) | CH3CH(OH)CH3 | A |

| Lactic Acid | CH3CHOHCOOH | A |

| Lard (Lard Oil) | Olein, stearin | A |

| Latex | Rubber emulsion | A |

| Lauryl Alcohol (n-Dodecanol) | CH3(CH2)10 CH2OH | A |

| Lead Chloride | PbCI2 | A |

| Lead Nitrate | Pb(NO3)2 | A |

| Lead Sulfamate | A | |

| Lime Bleach | B | |

| Lime Sulfur | CaS+CaSO4 | A |

| Linoleic Acid | C18H32O2 | A |

| Linseed Oil (Flaxseed Oil) | Glycerides | A |

| Lye (Potassium Hydroxide) | KOH | A |

| Magnesium Carbonate | MgCO3 | A |

| Magnesium Chloride | MgCI2O | A |

| Magnesium Hydroxide (Milk of Magnesia) | Mg(OH)2 | A |

| Magnesium Nitrate | Mg(NO3)2 &6H2O | A |

| Magnesium Sulfate (Epsom Salts) | MgSO4&7H2O | A |

| Maleic Acid | (CHCOOH)2 | A |

| Mayonnaise | Water, fats, oils | A |

| Mercuric Chloride | HgCI2 | A |

| Mercuric Cyanide | Hg(CN)2 | A |

| Mercurous Nitrate | Hg(NO3)2 &2H2O | A |

| Mercury | Hg | A |

| Methane | CH4 | B |

| Methyl (Methanol) | CH3OH | A 120°F |

| Methyl Alcohol (Methanol) | CH3OH | A |

| Methyl Cellosolve | CH3OCH2 CH2OH | A |

| Methylamine | CH3NH2 | A |

| Milk | A | |

| Mineral Oil (Petroleum) | Hydrocarbons | B |

| Molasses | A | |

| Mustard | A | |

| N,N-Dimethyl Formamide (DMF) | HCON(CH3)2 | A 120°F |

| Naphthalene (Tar Camphor) | C10H8 | A |

| Nickel Acetate | Ni(CH3CO2)2 | A |

| Nickel Chloride | NiCI2 | A |

| Nickel Nitrate | Ni(NO3)2&6H2O | A |

| Nickel Sulfate | NiSO4 | A |

| Nitric Acid _ 10% | HNO3 | A |

| Nitric Acid _ 25% | HNO3 | A |

| Nitric Acid _ 35% | HNO3 | B |

| Nitrobenzene | C6H5NO2 | B |

| o-Dichlorobenzene | C6H4CI2 | B |

| Oleic Acid (Red Oil) | C18H34O2 | B |

| Olive Oil | Mixed glycerides of acids | A |

| Oxalic Acid | (COOH)2 | A |

| Palmitic Acid | CH3(CH2)14 COOH | A |

| Paraffins (Paraffin Oil) | Hydrocarbons | A |

| Peanut Oil | Glycerides of fatty acids | A 70°F |

| Phosphoric Acid (Conc.) | H3PO4 | A 120°F |

| Phosphoric Acid _ 10% | H3PO4 | A 120°F |

| Phosphoric Acid _ 20% | H3PO4 | A 120°F |

| Phosphoric Acid _ 50% | H3PO4 | A 120°F |

| Photographic Developer | A | |

| Picric Acid (Carbazotic Acid) | (NO2)3 C6H2OH | B |

| Plating Solution _ Chrome | A 131°F | |

| Potassium Acetate | CH3CO2K | A |

| Potassium Bicarbonate | KHCO3 | A |

| Potassium Bisulfate | KHSO4 | A |

| Potassium Bromide | KBr | A |

| Potassium Carbonate (Potash) | K2CO3 | A |

| Potassium Chlorate | KCIO3 | A |

| Potassium Chloride | KCI | A |

| Potassium Chromate | K2CrO4 | A |

| Potassium Copper Cyanide | K3[Cu(CN)4] | A |

| Potassium Cyanide | KCN | A |

| Potassium Dichromate | K2Cr2O7 | A |

| Potassium Hydroxide (Caustic Potash) (Lye) | KOH | A |

| Potassium Iodide | KI | A |

| Potassium Nitrate (Saltpeter) | KNO3 | A |

| Potassium Nitrite | KNO2 | A |

| Potassium Permanganate (Purple Salt) | KMnO4 | B |

| Potassium Sulfate | K2SO4 | A |

| Potassium Sulfide | K2S | A |

| Potassium Sulfite | K2SO32H2O | A |

| Propyl (Propanol) | C2H5CH2OH | A |

| Propyl Alcohol (1-Propanol) | CH3CH2CH2OH | A |

| Propylene Glycol (Methyl Glycol) | C3H6(OH)2 | A |

| Pyroligneous Acid (Wood Vinegar) | A | |

| Rosin | C20H30O2 | A |

| Rust Inhibitors | A | |

| Sal Ammoniac (Ammonium Chloride) | NH4CI | A |

| Salad Dressing | Fats, oils, water | A |

| Salicylic Acid | A | |

| Salt Water (Brine) | NaCl/H2O | A |

| Sea Water (Brine) | A | |

| Sewage | A | |

| Silicone Oils (Versilube etc.) | [(CH3)2SiO2)]n | A |

| Silver Cyanide | AgCN | A |

| Silver Nitrate | AgNO3 | A |

| Soap Solutions | Salt of fatty acid in H2O | A |

| Sodium Acetate | CH3COONa | A |

| Sodium Aluminate | Na2Al2O4 | A |

| Sodium Bicarbonate (Baking Soda) | NaHCO3 | A |

| Sodium Bisulfite (Cream of Tartar) | NaHSO3 | A |

| Sodium Bisulfite (Niter Cake) | NaHSO4 | A |

| Sodium Borate | Na2B4O7 | A 140°F |

| Sodium Bromide | NaBr | A |

| Sodium Chlorate | NaCIO3 | A |

| Sodium Chloride (Table Salt) | NaCI | A |

| Sodium Chromate | Na2CrO4 | A |

| Sodium Cyanide | NaCN | A |

| Sodium Dichromate (Sodium Bichromate) | Na2Cr2O7&2H2O | A |

| Sodium Fluoride | NaF | A |

| Sodium Hydroxide (Caustic Soda) (Lye) | NaOH | A |

| Sodium Metasilicate | Na2SiO3 | A |

| Sodium Nitrate (Chile Saltpeter) | NaNO3 | A |

| Sodium Nitrite | NaNO2 | A |

| Sodium Perborate | NaBO3 | A |

| Sodium Peroxide (Sodium Dioxide) | Na2O2 | B |

| Sodium Phosphate (Tribasic) (TSP) | Na3PO4 | A |

| Sodium Silicates (Water Glass) | Na2O SiO2 | A |

| Sodium Sulfate (Salt Cake) (Thenardite) | Na2SO4 | A |

| Sodium Sulfide (Pentahydrate) | Na2S &5H2O | A |

| Sodium Sulfite | Na2SO3 | A |

| Sodium Thiosulfate (Antichlor) | Na2S2O3 | A |

| Soybean Oil | Triclycerides of acids | B |

| Stannic Chloride (Tin Chloride) | SnCI4 | A |

| Stannous Chloride (Tin Chloride) | SnCI2 | A |

| Starch | C6H10O5 | A |

| Stearic Acid | CH3(CH2)16CO2H | A |

| Stoddard Solvent | Petroleum distillate | A |

| Sulfur | S | A |

| Sulfur Dioxide | SO2 | A |

| Sulfuric Acid 10% | H2SO4 | A |

| Sulfuric Acid 25% | H2SO4 | A |

| Sulfuric Acid 50% | H2SO4 | A |

| Sulfuric Acid 60% | H2SO4 | A |

| Sulfuric Acid 75% | H2SO4 | A |

| Sulfurous Acid | H2SO3 | A |

| Tall Oil (Liquid Rosin) | Rosin acids | A |

| Tallow | Fat from cattle, sheep | B |

| Tannic Acid | C76H52O46 | A |

| Tanning Liquors | Tannic acid | A |

| Tar, Bituminous (Coal tar, pitch) | Mixture of aromatic & phenolic hydrocarbons | A |

| Tartaric Acid | C4H6O6 | A |

| Tertiary Butyl Alcohol | (CH3)3COH | B |

| Tetraethyl Lead | Pb(C2H5)4 | A |

| Thionyl Chloride | SOCI2 | B |

| Titanium Tetrachloride | TiCI4 | B |

| Tomato Pulp & Juice | A | |

| Transformer Oil (Petroleum) | Hydrocarbons | B |

| Triallyl Phosphate | P(OC3H5)3 | B |

| Trichloroacetic Acid (TCA) | CCI3COOH | B |

| Tricresyl Phosphate (Lindol) (TCP) | (CH3C6H4O)3 PO | B |

| Triethanol Amine (TEA) | N(C2H4OH)3 | A |

| Triethylene Glycol (TEG) | (CH2OCH2CH2OH)2 | A |

| Tung Oil (Wood Oil) | Fatty acids | A |

| Urea (Carbamide) | CO(NH2)2 | A |

| Urine | A | |

| Varnish (Oil, gum resins, oil of turpentine) | A | |

| Vinegar | Dilute acetic acid | A |

| Vinyl Acetate | CH3COOCHCH2 | B |

| Water, Distilled (Also Deionized) | H2O | A |

| Water, Fresh | H2O | A |

| Whiskey | Ethanol, esters, acids | A |

| White Sulfate Liquor | A | |

| Wines | A | |

| Zinc Acetate | Zn(C2H3O2)2 | A |

| Zinc Chloride | ZnCI2 | A |

| Zinc Sulfate | ZnSO4 | A |

Accessories

- Base Frame

- Coupling

- Coupling Guard

- Foundation bolt

- Strainer