Forged Ball Valve

Product Description

| Size | 1/4″ to 2” (8mm to 50mm) |

| Pressure Rating | ASME 150# to 900# |

| Design Standard | BS EN 17292 |

| Pressure / Temp. | ASME B 16.34 |

| Testing Std. | BS 12266-1 |

| Construction | Bolted |

| End Connection | Screwed, Socket Weld, Flanged, Butt-Weld, Nipple Extended |

| Operation | Lever |

| Material | A105N, LF2, F304L, F316L, F317, F321, F347,F5, F9, F11, F22, F91, F51, F53, F55, F60, Inconel, Monel, Alloy 20, Nickel Aluminium Bronze |

Related products

Ball Valves Three Piece Full bore with Locking device (PN40/PN63) Screw End, Socket Weld, Butt Weld

Description

Three Piece body from DN 15 to DN 100. Swing out economical design for Industrial & Process applications. Investment casting for body and end cap. End connections with Screwed end – Socket weld – Butt weld. Blow out proof stem design with LOTO Features for Lock out and Tag out arrangement.Technical Data :

- Size Range: DN 15(1/2”) – DN 100 (4”)

- Pressure rating: PN40 & PN63

- Temperature range: Up to 260 deg. C

- End Connections: Screwed End, Socket Weld, Butt Weld

- MOC : WCB, PTFE, CF8, 304 S/S, 316 S/S, MS, CF8M, SS, Carbon R’PTFE

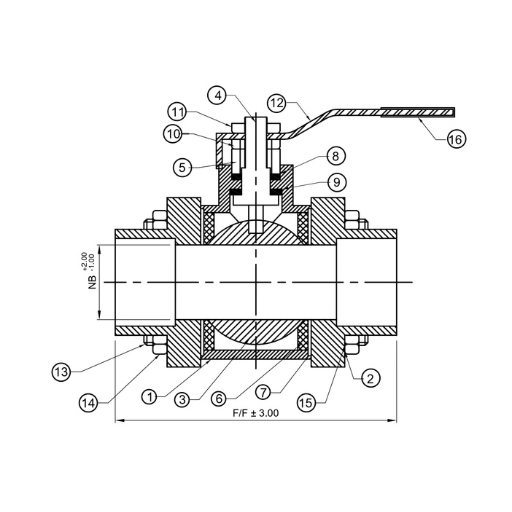

Ball Valves Three Piece, Full Bore (Screw End, Socket Weld) (150#, 300#, 600#, 800#)

Technical Data :

| Design Std. | As per ISO 17292 & BS 5351 |

| End Connection | Screwed End/Socket Weld |

| Testing & Std. | As per API 598 / ISO 5208 |

| Size, 150# | 15 mm to 50 mm (1/2" to 2") |

Material (MOC)

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Adaptor | WCB / CF8 / CF8M |

| 3 | Ball | CF8 / CF8M |

| 4 | Steam | SS304 / SS316 |

| 5 | Gland | SS304 / SS316 |

| 6 | Seat Ring | PTFE / GFT /CFT |

| 7 | Body Seal | PTFE / GFT /CFT |

| 8 | Gland Packing | PTFE / GFT /CFT |

| 9 | Steam Seal | PTFE / GFT /CFT |

| 10 | Gland Nut | MS/SS304 |

| 11 | Lever Nut | MS/SS304 |

| 12 | Lever | MS/SS |

| 13 | Stud | MS/SS304 |

| 14 | Stud Nut | MS/SS304 |

| 15 | Stud Washer | MS/SS304 |

| 16 | Lever Sleeve | PVC |

Dimensions 150#

| Size | NB | F/F | Thread Type |

| 15 | 12.5 | 62.5 | BSP/NPT/SW |

| 20 | 19.0 | 74.0 | BSP/NPT/SW |

| 25 | 25.0 | 87.0 | BSP/NPT/SW |

| 40 | 38.0 | 109.0 | BSP/NPT/SW |

| 50 | 50.0 | 110.0 | BSP/NPT/SW |

All Dimensions are in mm

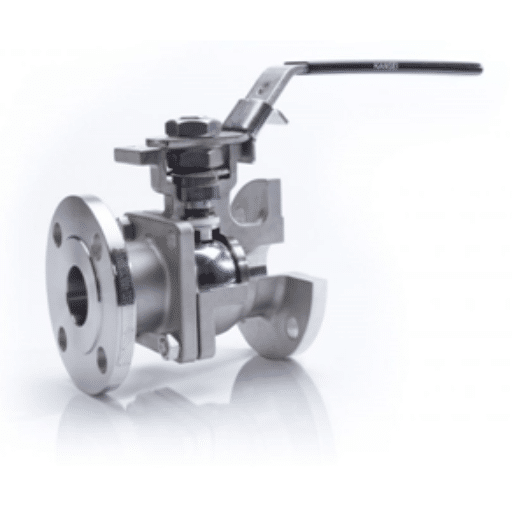

Ball Valves Two Piece, Metal Seated (150#, 300#)

Description

Kansei product KMS (Two-piece metal seated ball valve) in metal seated design as an additional option to our soft seated full port flanged series. This option increases the temperature rating to 750°F (399°C) and enhances wear resistance, while maintaining the proven safety and reliability of existing valves.Technical Data :

- Size Range: DN 15 (1/2”) – DN 200 (8”)

- Pressure: ASME Class 150 & 300

- Temperature range: Up to 400 deg. C

- Seat : SS 304 / SS316

- End Connections : Flanged ASME B16.5

- With ISO PAD

| Design Std. | As per ISO 17292 & BS 5351 |

| End Connection | Flanged End |

| Testing Std. | As per API 598 or ISO 5208 |

| Size 150# & 300# | 15 mm to 300 mm (1/2" to 12") |

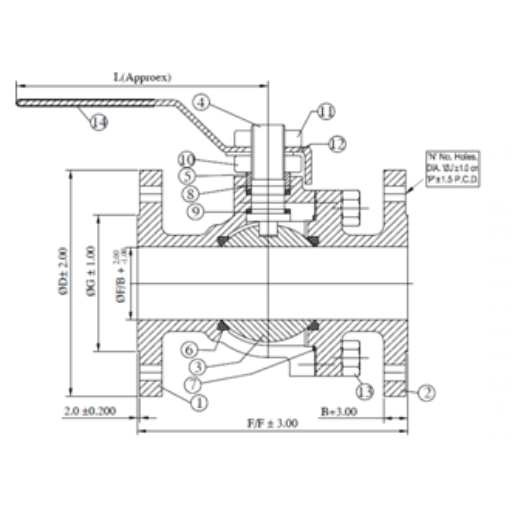

MATERIALS (MOC)

| Sr. No. | Description | Material |

| 1 | Body | CI /WCB / CF8 / CF8M |

| 2 | Cap | CI / WCB / CF8 / CF8M |

| 3 | Ball | CF8 / CF8M |

| 4 | Stem | SS304 / SS316 |

| 5 | Gland | SS304 / SS316 |

| 6 | Seat Ring | SS304 / SS316 |

| 7 | Body Seal | PTFE / GFT / CFT |

| 8 | Gland Packing | PTFE / GFT / CFT |

| 9 | Stem Seal | PTFE / GFT / CFT |

| 10 | Gland Nut | MS / SS304 |

| 11 | Lever Nut | MS / SS304 |

| 12 | Lever | MS / SS |

| 13 | Stud & Nut | Ms / SS304 |

| 14 | Lever Sleeve | PVC |

| 15 | End Cap | PVC |

DIMENSIONS 150#

| Size | Dia D | PCD | F/F |

| 15 | 90 | 60.5 | 108 |

| 20 | 100 | 70 | 117 |

| 25 | 110 | 79.5 | 127 |

| 40 | 125 | 98.5 | 165 |

| 50 | 150 | 120.5 | 178 |

| 65 | 180 | 139.5 | 191 |

| 80 | 190 | 152.5 | 203 |

| 100 | 230 | 190.5 | 229 |

| 150 | 280 | 241.5 | 267 |

| 200 | 345 | 298.5 | 292 |

| 250 | 405 | 362 | 330 |

| 300 | 485 | 432 | 356 |

DIMENSIONS 300#

| Size | Dia D | PCD | F/F |

| 15 | 95 | 66.5 | 140 |

| 20 | 115 | 82.5 | 152 |

| 25 | 125 | 89 | 165 |

| 40 | 155 | 114.5 | 190 |

| 50 | 165 | 127 | 216 |

| 65 | 190 | 149 | 241 |

| 80 | 210 | 168.5 | 283 |

| 100 | 255 | 200 | 305 |

| 150 | 320 | 270 | 403 |

| 200 | 380 | 330 | 419 |

| 250 | 445 | 387.5 | 457 |

| 300 | 520 | 451 | 502 |

All dimensions are in mm.

Cast Ball Valve

Product Description

| Size | 5/8" to 4” (15mm to 100mm) |

| Pressure Rating | ASME 150# |

| Design Standard | BS EN ISO 17292 |

| Test (Inspection) Standard | ISO 5208 / API 598 |

| Closer Member | SOLID / HOLLOW BALL |

| Construction | 2 PIECE / 3 PIECE SOFT SEATED |

| End Connection | Flanged as per 150# |

| Operation | Lever |

| Material | WCB, CF8, CF8M |

Cast Gate Valve

Product Description

| Size | 1-1/2" to 12” (40mm to 300mm) |

| Pressure Rating | ASME 150# |

| Design Standard | API 600 |

| Pressure / Temp. | ASME B 16.34 |

| Testing Std. | API 598 |

| Construction | Bolted Bonnet |

| End Connection | Flanged |

| Operation | Hand Wheel |

| Material | WCB, LCB, CF8, CF8M, CF3, CF3M, CG8M, CF8C, C5, C12, WC6, WC9, C12A, 4A, 5A, 6A, Inconel, Monel, CN7M, Nickel Aluminium Bronze |

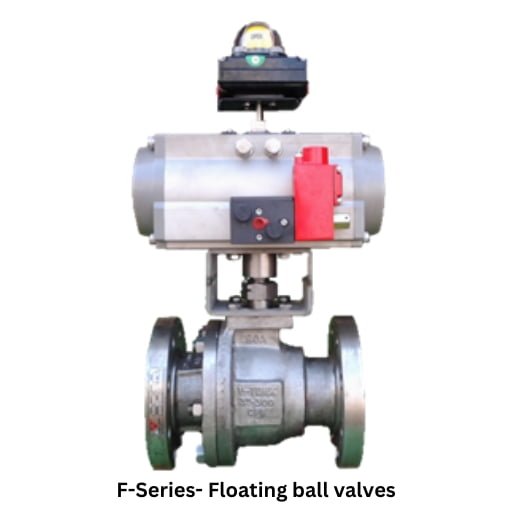

F-Series- Floating Ball Valves – V-TORK CONTROLS

F SERIES

Ball Valves are quarter turn – straight through valves, got its name from the ball that rotates to open & close the valve. Ball valves are widely used in applications where tight shut off is required. V-TORK manufactures Ball valves of 5 different types which are able to transfer gases, liquids & air. The Main advantages are the superior ease of operation, Low purchase & maintenance cost, rugged construction and longer service life.Specifications

- 2 Way

- Size ½” to 8” Class#150, 300 (Soft seated)

- Size ½” to 12” Class#150 (Metal Seated)

- Flanged Ends / Butt Welded

- Standard: BS 5351 / ISO 17292

Applications:

Range of Seat Materials PTFE/ CFT/GFT/PEEK/ Metal seat. Range of Material of Construction WCB / LCB / A105 / CF8 / CF8M / F304 / F316 / CF3 / CF3M / CD4MCU / CN7M & any special metallurgy on customer request. Range of Actuators Manual – Lever Operated, Gear Operated, Pneumatic Actuated, Motorized with Complete AutomationForged Gate Valve

Product Description

| 1/4" to 2” (8mm to 50mm) | |

| Class | 150#, 300#, 600#, 800#, 900#, 1500#, 2500# |

| Bore | Reduce Bore (Standard Bore), Full Bore |

| Design Standard | API 602 |

| Pressure / Temp. | ASME B 16.34 |

| Testing Std. | API 598 |

| Construction | Bolted Bonnet / Pressure Seal Bonnet (Welded Bonnet) |

| End Connection | Socket Weld, Screwed NPT, Screwed BSP, Flanged RF, Flanged RTJ, Butt-Weld, Nipple Extended (Pup Piece) |

| Operation | Hand Wheel |

| Material | A105N, LF2, F304L, F316L, F317, F321, F347,F5, F9, F11, F22, F91, F51, F53, F55, F60, Inconel, Monel, Alloy 20, Nickel Aluminium Bronze |

Forged Globe Valve

Product Description

| Size | Size: 1/4" to 2” (8mm to 50mm) |

| Class | ASME 150# to 2500# |

| Design Standard | API 602 |

| Pressure / Temp. | ASME B 16.34 |

| Testing Std. | API 598 |

| Construction | Bolted Bonnet / Pressure Seal Bonnet |

| End Connection | Screwed, Socket Weld, Flanged, Butt-Weld, Nipple Extended |

| Operation | Hand Wheel |

| Material | A105N, LF2, F304L, F316L, F317, F321, F347,F5, F9, F11, F22, F91, F51, F53, F55, F60, Inconel, Monel, Alloy 20, Nickel Aluminium Bronze |