B-900 – Bi Directional, Two piece Rugged Knife Gate Valve – V-TORK CONTROLS

B-900

Specifications

- Size Range: 2” to 40” (50MM to 1000MM)

- Pressure Rating: 2”- 40” – 150 PSI CWP

- Flow Direction can be mounted in both flow directions

V-TORK®B-900 two piece rugged Bi Directional Knife Gate Valve features full port design with zero Leakage by the unique transverse seal concept. The shearing gate design avoids the obstructions in the flowing media. Gate perimeter is guided through resilient seat which is mechanically retained, allowing for zero leakage isolation regardless of flow direction.

Applications:

Liquid/Slurry Application: Mining, Minerals (Bauxite Beneficiation Plant, Bauxite slurry, Cement (Slag Granulation Plant), Metals (Beneficiation Plant, Iron ore slurry Suction line), Lime Slurry, Flue gas desulfurization, Sand & gravel, Coal, Phosphate, Sea Water, Kaolin, Alumina, Soda Ash etc.

Unique Design Features:

Replaceable gland seal in line under full pressure.

Glandless design

Full port design to eliminate the turbulence & pressure-drop across the valve

High rigid yoke / support plate design to avoid shock loads

Operation: Lever, Hand Wheel, Chain Wheel, Bevel Gear, Hydraulic Cylinder, Pneumatic Cylinder, Electrical Actuator etc.

Accessories: Limit Switch, Solenoid Valve, Positioner Air Filter Regulator etc.

Related products

B-360 – Bi-Directional Two Piece type Knife gate valves – V-TORK CONTROLS

B-360

Slurry Knife Gate Valves

Specifications

- Bi Directional, Flanged Type

- Size 2” to 40” (50mm to 1000mm)

- Resilient Seated (U-Seal)

- Two Piece Fabricated Construction

- 150 PSI CWP

- Standard: MSS SP-81, MSS SP-148, MSS SP-151

Applications:

Liquid/Slurry Application: Abrasive Slurries in Mineral Industries, Pulp Slurry, Chemical Slurry, Molasses, Raw Water Intake, Ash Slurries in Thermal Power Plant, Chemical Slurries in Chemical Process Industries, Sugar Juice in Sugar Industries Bulk Handling (Solids & Powders): Pneumatic Conveying systems, Detergent Powders/Cake, Boiler bed ash, Carbon Black, Coal handling, Lime powder handling applications. Gas Application: Blast Furnace Gas in Steel industries, Pulverized coal fired lines in Thermal Power Plants, Hot gas handling. Powder Applications: Lime powder, Silica/ Magnesium Oxide/ Calcium Oxide/ Al Oxide/ Zyconium Oxide. Range of Material of Construction CI / DI / WCB / CF8 / CF8M / CF3M / CG8M / SMO254 / Duplex 2205 & Special Materials on Request Range of Seat Materials EPDM / Viton / Natural Rubber / Nitrile/ PTFE/ CFT/GFT Range of Actuators Hand Wheel, Lever Operated, Chain Wheel, Bevel Gear, Pneumatic Double Acting/Single Acting Cylinder, Hydraulic Cylinder, Electro-Pneumatic Operation, Motorized Range of Accessories Solenoid Valve, Limit Switch, Proximity Switch, Junction Box, Positioner, Accumulator for Emergency Shut Off, Wear Rings, AFR, Speed Control Valves Range of Addl. Features Deflection cone, V-Orifice, Purge Port, Stem Extension, Fail Safe System, Locking Arrangement, Renewable seats, Non raising Stem arrangement.B-540 – Bi-Directional Lug Type Slurry valve (Short face to face) – V-TORK CONTROLS

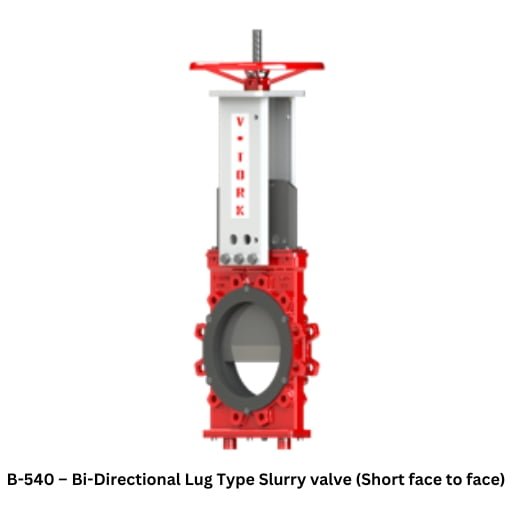

B-540

Slurry Knife Gate Valves

Specifications

- Bi Directional, Lug Type

- Size 2” to 54” (50mm to 1350mm)

- Dual Elastomer Seals with Retainer Rings

- Single Piece Construction

- 150 PSI/300 PSI (18” to 54”) CWP

- Standard: V-TORK Std

Applications:

Liquid/Slurry Application: Abrasive Slurries in Mineral Industries, Pulp Slurry, Chemical Slurry, Molasses, Raw Water Intake, Ash Slurries in Thermal Power Plant, Chemical Slurries in Chemical Process Industries, Sugar Juice in Sugar Industries Bulk Handling (Solids & Powders): Pneumatic Conveying systems, Detergent Powders/Cake, Boiler bed ash, Carbon Black, Coal handling, Lime powder handling applications. Gas Application: Blast Furnace Gas in Steel industries, Pulverized coal fired lines in Thermal Power Plants, Hot gas handling. Powder Applications: Lime powder, Silica/ Magnesium Oxide/ Calcium Oxide/ Al Oxide/ Zyconium Oxide. Range of Material of Construction DI / WCB & Special Materials on Request Range of Seat Materials EPDM /Natural Rubber (Special material on request) Range of Actuators Hand Wheel, Lever Operated, Chain Wheel, Bevel Gear, Pneumatic Double Acting/Single Acting Cylinder, Hydraulic Cylinder, Electro-Pneumatic Operation, Motorized Range of Accessories Solenoid Valve, Limit Switch, Proximity Switch, Junction Box, Positioner, Accumulator for Emergency Shut Off, Wear Rings, AFR, Speed Control Valves, Reed Limit Switch. Range of Addl. Features Purge Port, Drain Port, Stem Extension, Fail Safe System, Locking Arrangement, Non-Raising Stem arrangement…B-540 – Bi-Directional Lug Type Slurry valve (Short face to face) Knife Gate Valves – V-TORK CONTROLS

B-540

Specifications

- Bi Directional, Lug Type

- Size 2” to 54” (50mm to 1350mm)

- Dual Elastomer Seals with Retainer Rings

- Single Piece Construction

- 150 PSI/300 PSI (18” to 54”) CWP

- Standard: V-TORK Std

Applications:

Liquid/Slurry Application: Abrasive Slurries in Mineral Industries, Pulp Slurry, Chemical Slurry, Molasses, Raw Water Intake, Ash Slurries in Thermal Power Plant, Chemical Slurries in Chemical Process Industries, Sugar Juice in Sugar Industries Bulk Handling (Solids & Powders): Pneumatic Conveying systems, Detergent Powders/Cake, Boiler bed ash, Carbon Black, Coal handling, Lime powder handling applications. Gas Application: Blast Furnace Gas in Steel industries, Pulverized coal fired lines in Thermal Power Plants, Hot gas handling. Powder Applications: Lime powder, Silica/ Magnesium Oxide/ Calcium Oxide/ Al Oxide/ Zyconium Oxide. Range of Material of Construction DI / WCB & Special Materials on Request Range of Seat Materials EPDM /Natural Rubber (Special material on request) Range of Actuators Hand Wheel, Lever Operated, Chain Wheel, Bevel Gear, Pneumatic Double Acting/Single Acting Cylinder, Hydraulic Cylinder, Electro-Pneumatic Operation, Motorized Range of Accessories Solenoid Valve, Limit Switch, Proximity Switch, Junction Box, Positioner, Accumulator for Emergency Shut Off, Wear Rings, AFR, Speed Control Valves, Reed Limit Switch. Range of Addl. Features Purge Port, Drain Port, Stem Extension, Fail Safe System, Locking Arrangement, Non-Raising Stem arrangement…B-630 – Bi-Directional O Port Knife gate valves – V-TORK CONTROLS

B-630

Slurry Knife Gate Valves

Specifications

- Bi Directional, Lug Type

- Size 4” to 24” (100mm to 600mm)

- Metal Seated / Resilient Seated

- Split Body Construction

- 150 PSI CWP

- Standard: MSS SP-81, MSS SP-148, MSS SP-151

Applications:

Liquid/Slurry Application: Abrasive Slurries in Mineral Industries, Pulp Slurry, Chemical Slurry, Molasses, Raw Water Intake, Ash Slurries in Thermal Power Plant, Chemical Slurries in Chemical Process Industries, Sugar Juice in Sugar Industries Bulk Handling (Solids & Powders): Pneumatic Conveying systems, Detergent Powders/Cake, Boiler bed ash, Carbon Black, Coal handling, Lime powder handling applications. Gas Application: Blast Furnace Gas in Steel industries, Pulverized coal fired lines in Thermal Power Plants, Hot gas handling. Powder Applications: Lime powder, Silica/ Magnesium Oxide/ Calcium Oxide/ Al Oxide/ Zyconium Oxide. Range of Material of Construction CI / DI / WCB / CF8 / CF8M / CF3M / CG8M / SMO254 / Duplex 2205 & Special Materials on Request Range of Seat Materials EPDM / Viton / Natural Rubber / Nitrile/ PTFE/ CFT/GFT Range of Actuators Hand Wheel, Lever Operated, Chain Wheel, Bevel Gear, Pneumatic Double Acting/Single Acting Cylinder, Hydraulic Cylinder, Electro-Pneumatic Operation, Motorized Range of Accessories Solenoid Valve, Limit Switch, Proximity Switch, Junction Box, Positioner, Accumulator for Emergency Shut Off, Wear Rings, AFR, Speed Control Valves Range of Addl. Features Deflection cone, V-Orifice, Purge Port, Stem Extension, Fail Safe System, Locking Arrangement, Renewable seats, Non raising Stem arrangement.B-810 –High performance Bi-Directional flanged Type Slurry valve – V-TORK CONTROLS

B-810

Slurry Knife Gate Valves

Specifications

- Bi Directional, Lug Type

- Size 2” to 36” (50mm to 900mm)

- Dual Elastomer Seals with Retainer Rings

- Single Piece Construction

- 740 psi CWP/51 bar/Class #300

- Standard: V-TORK Std.

Applications:

Liquid/Slurry Application: Abrasive Slurries in Mineral Industries, Pulp Slurry, Chemical Slurry, Molasses, Raw Water Intake, Ash Slurries in Thermal Power Plant, Chemical Slurries in Chemical Process Industries, Sugar Juice in Sugar Industries Bulk Handling (Solids & Powders): Pneumatic Conveying systems, Detergent Powders/Cake, Boiler bed ash, Carbon Black, Coal handling, Lime powder handling applications. Gas Application: Blast Furnace Gas in Steel industries, Pulverized coal fired lines in Thermal Power Plants, Hot gas handling. Powder Applications: Lime powder, Silica/ Magnesium Oxide/ Calcium Oxide/ Al Oxide/ Zyconium Oxide. Range of Material of Construction CI / DI / WCB / CF8 / CF8M / CF3M / CG8M / SMO254 / Duplex 2205 & Special Materials on Request Range of Seat Materials EPDM / Viton / Natural Rubber / Nitrile/ PTFE/ CFT/GFT Range of Actuators Hand Wheel, Lever Operated, Chain Wheel, Bevel Gear, Pneumatic Double Acting/Single Acting Cylinder, Hydraulic Cylinder, Electro-Pneumatic Operation, Motorized Range of Accessories Solenoid Valve, Limit Switch, Proximity Switch, Junction Box, Positioner, Accumulator for Emergency Shut Off, Wear Rings, AFR, Speed Control Valves Range of Addl. Features Deflection cone, V-Orifice, Purge Port, Stem Extension, Fail Safe System, Locking Arrangement, Renewable seats, Non raising Stem arrangement.C-Series- Concentric type Butterfly Valves – V-TORK CONTROLS

Butterfly Valves

C SERIES

Specifications

- Size: 1” to 100” (40mm to 2500mm)

- Wafer, Lug, Double Flanged Ends

- Class#150, PN10

- Concentric Type

- Molded Seated / Renewable Seated

- Standard: BS 5155/ API 609/ AWWA C 504

Applications:

V-TORK Butterfly Valves are well suited for handling larger flow of liquids and gases alternately of low pressure and for handling of liquids with suspended solids (Slurries). Size 1” to 50” (25mm to 1250mm) Fabricated Valves as per customer requirement. Range of Material of Construction Disc: WCB / CF8 / CF8M / DI / CI & any special metallurgy on customer request; Stem: AISI 410 / 304 / 316; Body: CI / WCB / CF8 / CF8M Range of Seat Materials EPDM / Viton / Natural Rubber / Nitrile /PTFE/Metal Seat Range of Actuators Manual – Lever Operated, Gear Operated, Pneumatic Actuated, Motorized with Complete AutomationF-Series- Floating Ball Valves – V-TORK CONTROLS

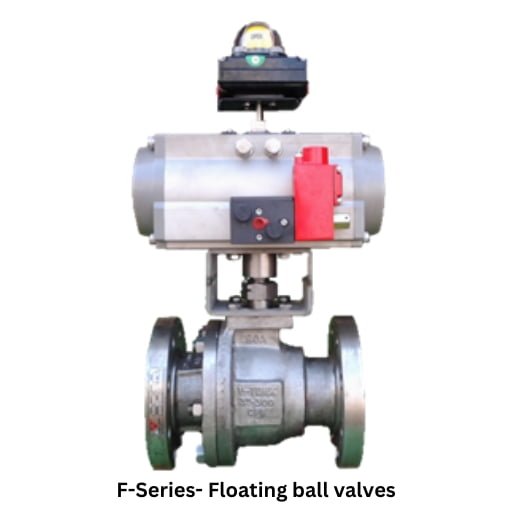

F SERIES

Ball Valves are quarter turn – straight through valves, got its name from the ball that rotates to open & close the valve. Ball valves are widely used in applications where tight shut off is required. V-TORK manufactures Ball valves of 5 different types which are able to transfer gases, liquids & air. The Main advantages are the superior ease of operation, Low purchase & maintenance cost, rugged construction and longer service life.Specifications

- 2 Way

- Size ½” to 8” Class#150, 300 (Soft seated)

- Size ½” to 12” Class#150 (Metal Seated)

- Flanged Ends / Butt Welded

- Standard: BS 5351 / ISO 17292

Applications:

Range of Seat Materials PTFE/ CFT/GFT/PEEK/ Metal seat. Range of Material of Construction WCB / LCB / A105 / CF8 / CF8M / F304 / F316 / CF3 / CF3M / CD4MCU / CN7M & any special metallurgy on customer request. Range of Actuators Manual – Lever Operated, Gear Operated, Pneumatic Actuated, Motorized with Complete AutomationU-304- Uni-Directional, Flanged type Bonnetted Knife gate valves – V-TORK CONTROLS

U -304 AWWA

Awwa Knife Gate Valves

V-TORK AWWA/water Knife Gate valve standard describes Bonneted / Bonnetless and one piece/two piece construction which is made of stainless steel /cast iron /ductile iron body with resilient or metal seated knife gate valves. Theses AWWA valves are especially used in water, wastewater, and sludge water systems. V-TORK Valves are specially manufactured by AWWA standard to suit critical water applications.Specifications

- UniDirectional, Flanged Type

- Size 2” to 120” (50mm to 3400mm)

- Bonneted / Bonnet Less

- Metal Seated / Soft Seated

- 150 PSI CWP

- Standard: AWWA C520-10