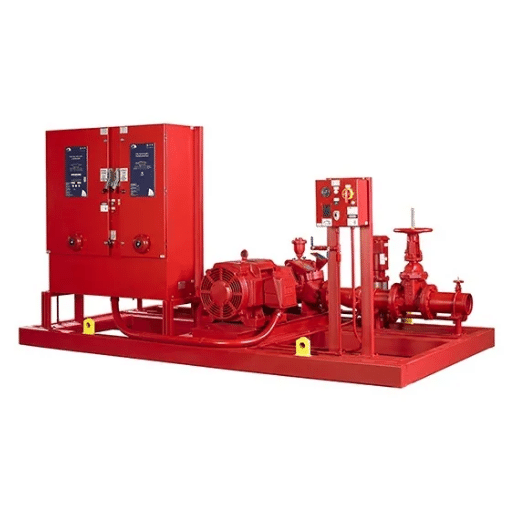

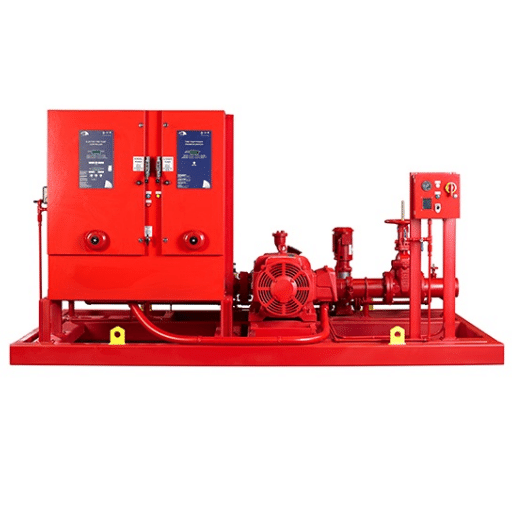

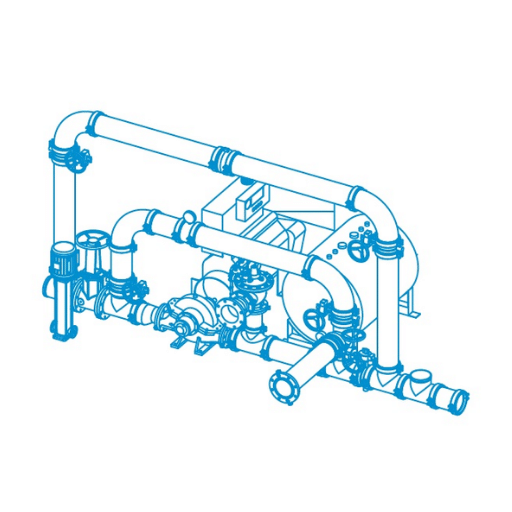

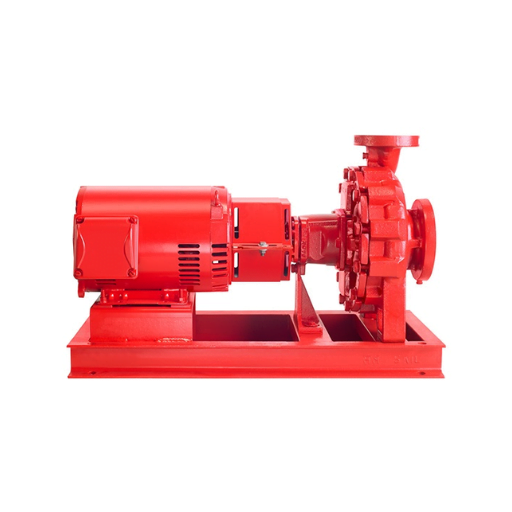

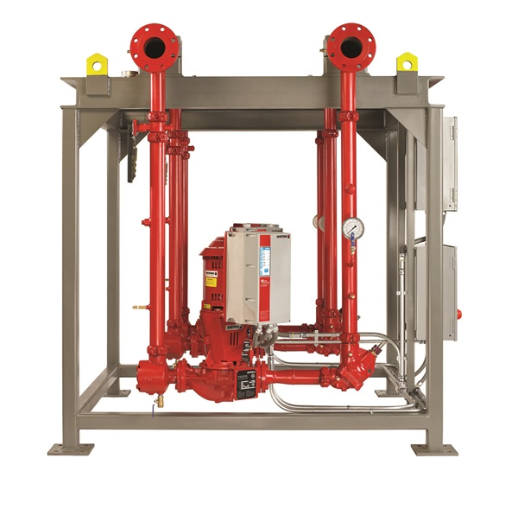

Armstrong Firepak Horizontal Split Case

- Applications-Fire-protection of buildings and other built infrastructure.

- Description-The Horizontal Split-Case (HSC) FirePak offering features the full range of Armstrong HSC fire pumps, electric or diesel-driven, and controller. All mounted, piped, and wired on a base at the factory.

- Materials (MOC)-Metal base, piping, pump, and control panel; switchgear; electric motor/ diesel engine

- Configuration-Optional features include jockey pump, jockey pump controller city by-pass loop, flow meter loop, main relief valve plus waste cone, and diesel fuel tank. 50 Hz and 60 Hz electric versions.

- Performance range-500 – 3000 USgpm

Description

Benefits & Features

Lowest installed cost and smallest footprint

- Factory configured and assembled for up to 30% lower cost and up to 90% less installation time over equivalent separate component supply installation.

- Complete pre-assembled package for eliminating onsite installation waste and motor-pump alignments.

Minimal project and operating risk

- Complete pre-assembled package in accordance with all applicable NFPA codes and standards for carefree site approval.

- Product design, assembly and testing in a controlled ISO 14000 factory environment for trouble-free installation and lifetime performance.

- Single-source responsibility for convenient project and product support.

Related products

Armstrong 4030 End Suctionbase Mounted Pumps

- Applications — HVAC-system pumping; light industrial/ process pumping

- Description — The Armstrong 4030 horizontal end-suction (ES) pumps are engineered to substantially reduce cost over competitor designs across installation, operation, and lifetime maintenance. High-efficiency NEMA-premium motors ensure low energy consumption and cost.

- Materials (MOC) — Cast iron, ductile iron, or bronze casing, Cast iron or bronze impeller

- Configuration Inside — single spring mechanical seal.

- Performance range — Up to 5,000 USgpm (315 L/s) flow; up to 600 ft (180 m) head

- Temperature — 250°F (121°C)

- Power Range — 0.33 hp to 300 hp (0.25 kW to 200 kW)

- Size — 1" to 8” (25 mm to 200 mm)

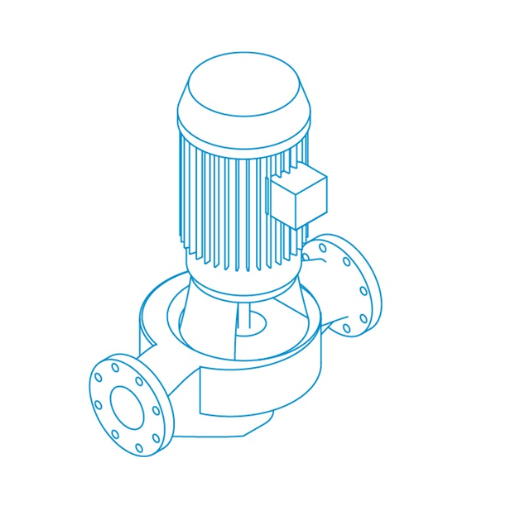

Armstrong 4380 vertical in-line pumps

- Applications-HVAC-system pumping; light industrial/ process pumping. (water or glycol based)

- Description-The Armstrong 4380 pipe-mounted pumps are designed for space-saving installation and long service life.

- Materials(MOC)-Cast iron or ductile iron casing, Silicon sintered carbide mechanical seal, Cast iron or bronze impeller.

- Configuration-Inside single-spring mechanical seal.

- Performance range-Up to 2,500 USgpm (160 L/s) flow; up to 300 ft (90 m) head

- Temperature-250°F (121°C)

- Power Range-0.33 hp to 60 hp (0.25 kW to 45 kW)

- Size-1.5″ to 8″ (40 mm to 200 mm)

Armstrong Design Envelope 9521 Integrated Plant Control System (IPC 9521)

- Applications-Automated chiller plant control for optimizing variable primary flow water-cooled chiller plants. The 9521 IPC works in a variable primary configuration and keeps the entire plant including water-cooled chillers, cooling towers, chilled water and condenser pumps running smoothly.

- Description-The Armstrong Integrated Water-Cooled Chiller Plant Control System (IPC) boosts energy efficiencies of new and existing chiller plant installations to leading class levels. The IPC 9521 works with all variable primary configurations, keeping the entire plant – including water-cooled chillers, cooling towers, chilled water and condenser pumps – running at optimum performance and occupant comfort.

- Configuration-Integrates with all brands of chillers, pumps, and automation systems. Installs directly with chiller plant equipment. If preferred, the IPC connects seamlessly with any central building automation system (BAS) maintaining full control of the chilled water plant through the BAS

- Performance range-Controls up to five chillers, five cooling towers and five pumps. No limitations in plant size and cooling capacity.

- Power Range-No limitations in plant cooling capacity

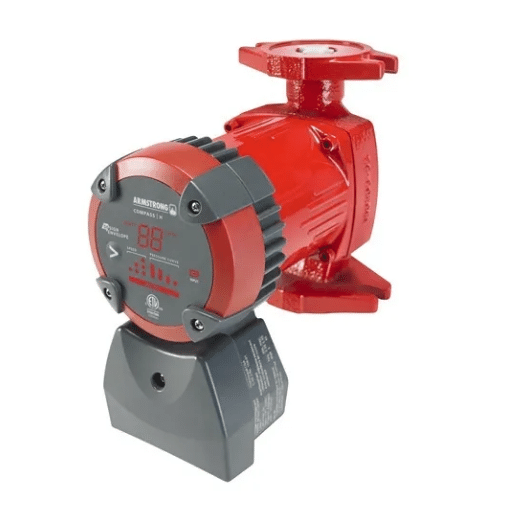

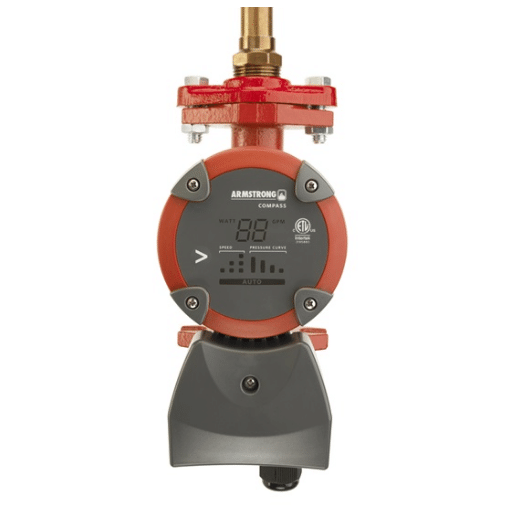

Armstrong Design Envelope Compass h Circulators

- Applications-Residential heating and cooling; potable water supply.

- Description-The Armstrong Compass H is an energy-efficient variable speed wet-rotor circulator. Designed to replace existing fixed speed circulators, with popular flange-to-flange dimensions, Compass H can be considered a universal replacement for all circulators in its capacity range.

- Materials (MOC)-Cast iron and stainless steel volutes.

- Configuration-Eight operation modes with patented “Auto” algorithm, four Sensorless modes and three fixed speed modes. 50 Hz and 60 Hz designs

- Performance range-Up to 20 USgpm (1.26 L/s) flow; up to 20 ft (6.1 m) head

- Temperature-Max ambient temp. 40°C; max water temp. 110°C

- Power Range-5 W to 45 W

- Size-1″

Armstrong Design Envelope Integrated Pumping System (IPS 4000)

- Applications-Multi-pump control for heated – or chilled – water system optimization in buildings.

- Description-The Design Envelope Integrated Pumping System (IPS 4000) is an advanced multi-zone control that directly integrates with pumping units to optimize energy performance, system handling, and installation.

- Materials (MOC)-Enclosure, circuitry, software

- Configuration-Integrates seamlessly with Armstrong Design Envelope pumps in a headered configuration.

- Performance range-Up to 8 pumps, 16 zones (variable primary, secondary or tertiary) and 8 flow sensitive equipment (variable primary) IPS 4001w / IPS 4501w for up to 3 pumps, 3 zones and 3 flow sensitive equipment IPS 4002w / IPS 4502w for up to 4 pumps, 6 zones and 4 flow sensitive equipment IPS 4003w / IPS 4503w for up to 6 pumps, 12 zones and 6 flow sensitive equipment IPS 4004w / IPS 4504w for up to 8 pumps, 16 zones and 8 flow sensitive equipment

- Power Range-No limitations in system size and capacity.

- Size-No limitations in system size.

Armstrong Design Envelope Intelligent Fluid Management System

- Applications-Commercial or industrial closed-loop systems, including HVAC chilled-water systems, boiler systems, cooling tower systems, or process water loops.

- Description-The Armstrong Intelligent Fluid Management System (iFMS) integrates superior pump- and control technology into a single pumping solution yielding both compact and carefree installation as well as superior energy performance. iFMS is ideally suited for partial or all variable speed chilled-water plant applications (variable primary flow, variable secondary flow, variable condenser water flow). In combination with Parallel Sensorless control iFMS saves 30% or more in energy over any other parallel pumping configuration available today.

- Configuration-Up to 4 pumps in one unit. Catalogue-based pre-engineered solutions or designed to customer specification. Integrated control system (IPS 4000, IPC 11550) or connecting to chiller plant/BMS control. Optional single point power panel

Armstrong Expansion Tanks

- Applications-Pressure stabilization in water based mechanical systems such as booster installations, boiler systems, and chiller plants

- Description-Armstrong Expansion Tanks are designed to reduce tank sizes by up to 80% over standard designs. Expansion tanks use compressed air to maintain system pressures by accepting and expelling the changing volume of water as it heats and cools. Diaphragm or bladder tank designs isolate the expanded water from the pressure controlling air cushion – which is pre-charged at the factory and can be adjusted in the field to meet final system requirements

- Materials (MOC)-Carbon steel (shell), heavy duty Butyl (diaphragm)

- Performance range-AET plain steel expansion tanks: 15 to 525 USgpm flow. AX diaphragm expansion tanks: 8 to 211 USgpm flow. Type L bladder type expansion tanks: 10 to 1056 USgpm flow.

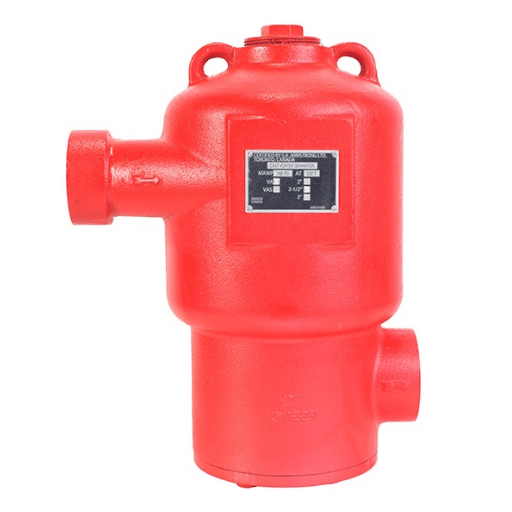

Armstrong Vortex Air Separators

- Applications-Air removal from hydronic and HVAC systems – air can get trapped during initial fill, during routine equipment maintenance (including pressure upkeep), and due to the use of cooling towers.

- Description-The Armstrong vortex air separators create a vortex or whirlpool action, sending the heavier air-free water to the outer portion of the tank, and allowing the lighter air-entrained water mixture to move into the lower-velocity center. At the center of the vortex the air is released from the water, forms bubbles and exits through an air vent or compression tank installed above it.

- Materials (MOC)-Cast iron or fabricated steel (shell), stainless steel mesh (strainer)