Armstrong Expansion Tanks

- Applications-Pressure stabilization in water based mechanical systems such as booster installations, boiler systems, and chiller plants

- Description-Armstrong Expansion Tanks are designed to reduce tank sizes by up to 80% over standard designs. Expansion tanks use compressed air to maintain system pressures by accepting and expelling the changing volume of water as it heats and cools. Diaphragm or bladder tank designs isolate the expanded water from the pressure controlling air cushion – which is pre-charged at the factory and can be adjusted in the field to meet final system requirements

- Materials (MOC)-Carbon steel (shell), heavy duty Butyl (diaphragm)

- Performance range-AET plain steel expansion tanks: 15 to 525 USgpm flow.

AX diaphragm expansion tanks: 8 to 211 USgpm flow.

Type L bladder type expansion tanks: 10 to 1056 USgpm flow.

Description

Benefits & Features

Lowest footprint

- Space saving design for up to 80% reduced footprint over standard tank designs

Low operating cost and risk

- Eliminates air ingress and dampens pressure transients (water hammer) for reduced system corrosion and stress, ultimately extending service intervals and overall system life.

- Stabilizes system pressure, maintaining optimum levels of a critical operating parameter.

- Reduces need for chemical treatment.

Related products

Armstrong 4280 Motor Mounted Pumps

- Applications-HVAC-system pumping; light industrial / process pumping.

- Description-The Armstrong 4280 horizontal end-suction pumps are equipped with close-coupled motors to minimize footprint requirements.

- Materials(MOC)-Cast iron, ductile iron, or bronze casing, Cast iron or bronze impeller.

- Configuration-Inside single-spring mechanical seal

- Performance range-Up to 2,000 USgpm (125 L/s) flow; up to 400 f (120 m)

- Temperature-250°F (121°C)

- Power Range-0.33 hp to 60 hp (0.25 kW to 45 kW)

- Size-1" to 6” (25 mm to 150 mm)

Armstrong 4300 vertical in-line pumps

- Applications-HVAC-system pumping; light industrial/ process pumping (water or glycol based)

- Description-The Armstrong 4300 pipe-mounted pumps are designed for space-saving installation, high operating efficiency, and long service life

- Materials(MOC)-Cast, ductile iron or bronze casing, Cast iron or bronze impeller

- Configuration-Outside balanced or inside single spring mechanical seal

- Performance range-Up to 28,000 USgpm (1,800 L/s) Flow; up to 500 ft (150 m) Head

- Temperature-300oF (150oC)

- Power Range-1 hp to 1250 hp (0.75 kW to 900 kW)

- Size-1.5″ to 20” (40 mm to 500 mm)

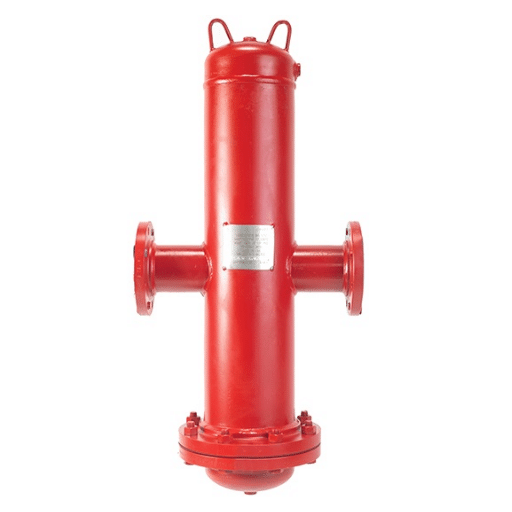

Armstrong Air & Dirt Separators

- Applications-Dirt and air removal from hydronic and HVAC systems.

- Description-The Armstrong dirt & air separators (DAS) are designed to eliminate trapped air and suspended dirt particles associated with the start-up and maintenance of hydronic and HVAC systems.

- Materials (MOC)-Carbon steel (shell), stainless steel (coalescing medium), styrene butadiene rubber (gasket)

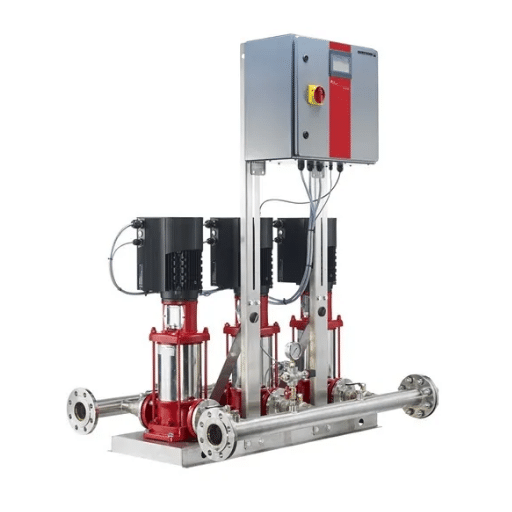

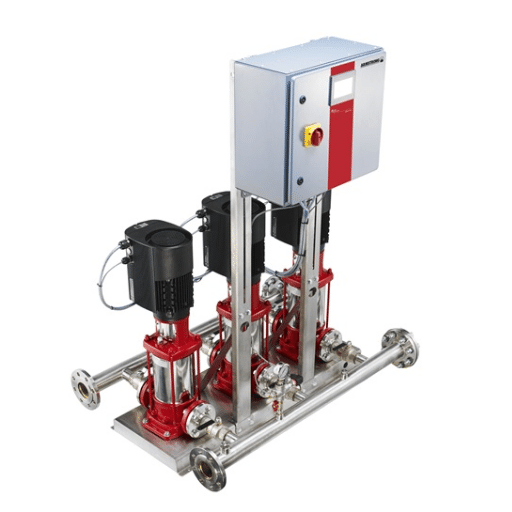

Armstrong Design Envelope 6800 Vertical Multistage Boosters

- Applications-New and retrofit water boosting installations in mid to large size residential, commercial, or industrial settings (such as apartment buildings, office towers, hospitals, hotels, schools, water treatment plants, factories, etc.)

- Description-The Armstrong Design Envelope 6800 Boosters are fully assembled, programmed, integrated and factory-tested turn-key booster systems. They are equipped with vertical multistage pumps and come in arrangements of 2 to 5 pumps. The integrated controls allow for superior performance and energy efficiency across broad operating envelopes. Most suitable for applications where energy consumption and low maintenance are critical, installation space comes at a premium, and occupant comfort is a high priority.

- Materials (MOC)-Piping: stainless steel 304

- Configuration-The 6800 Booster range offers enhanced features, such as improved touchscreens, more performance envelopes, an easy-to-use selection software, and onboard energy and flow readings both present and historic. For the full improved feature set please refer to the Solution Outline for this product.

- Performance range-Up to 2000 USgpm (450 m3/hr) flow; up to 370 psi (22 bar) pressure

- Power Range-Up to 250 hp (up to 185 kW)

Armstrong Design Envelope Intelligent Fluid Management System

- Applications-Commercial or industrial closed-loop systems, including HVAC chilled-water systems, boiler systems, cooling tower systems, or process water loops.

- Description-The Armstrong Intelligent Fluid Management System (iFMS) integrates superior pump- and control technology into a single pumping solution yielding both compact and carefree installation as well as superior energy performance. iFMS is ideally suited for partial or all variable speed chilled-water plant applications (variable primary flow, variable secondary flow, variable condenser water flow). In combination with Parallel Sensorless control iFMS saves 30% or more in energy over any other parallel pumping configuration available today.

- Configuration-Up to 4 pumps in one unit. Catalogue-based pre-engineered solutions or designed to customer specification. Integrated control system (IPS 4000, IPC 11550) or connecting to chiller plant/BMS control. Optional single point power panel

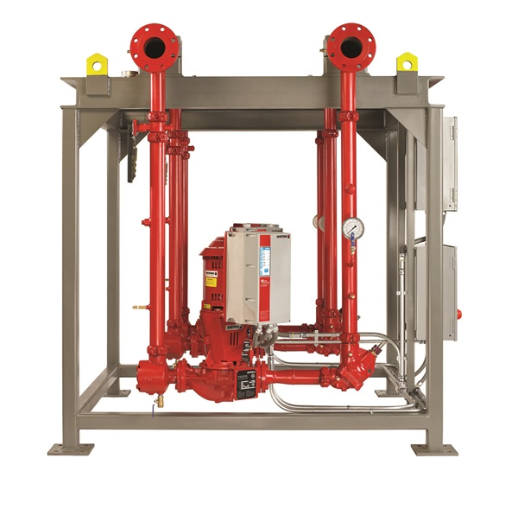

Armstrong Firepak Vertical In-line

- Applications-Fire-protection of buildings and other built infrastructure.

- Description-The Armstrong Vertical In-line (VIL) FirePak line features the full range of VIL fire pumps with electric motor and controller. All mounted, piped, and wired on a base at the factory. The complete package is designed to fit through a standard door.

- Materials (MOC)-Metal base, piping, pump, and control panel; switchgear; electric motor.

- Configuration-Options available include jockey pump and jockey pump controller. 50 Hz and 60 Hz designs. UL, ULC, and/or FM certification

- Performance range-50 – 1500 USgpm

Armstrong Flo-Trex Valves

- Applications-HVAC-system pumping; general purpose pumping; industrial/ process pumping (water or glycol based).

- Description-The Armstrong Flo-Trex Valves (FTV) are multi-function pump fittings that reduce equipment and installation costs.

- Materials (MOC)-Cast iron, ductile iron; grooved, flanged or threaded connections.

- Performance range-Suitable for all Armstrong commercial pumps.

- Temperature-230 °F (110 °C)

- Size-1.25” to 20” (32 mm to 500 mm)

Full View Sight Glass (PN10)

Applications:

Industrial facilities, oil refineries, bath soap manufacturing plane, gas industries, petrochemical complex, high viscous process media, building construction, environmental water treatments, synthetics, plastic and resin industries, polymer manufacturing plant, food industries (chocolate, sauce etc.), fertilizer industries etc.Technical Data :

| Design Std. | As per BS 5352 |

| Testing Std. | As per API 598 |

| End Connection | As per ANSI B16.5 |

| Size | ½” to 4” (15 mm to100 mm) |

| Pressure rating | PN10 |

| Maximum working pressure | 10 Kg/cm2 |

| Test pressure | 15 Kg/cm2 |

Dimensions

| Size | A | B | C |

| 15 | 153 | 51 | 137 |

| 20 | 153 | 51 | 137 |

| 25 | 153 | 51 | 137 |

| 40 | 178 | 64 | 146 |

| 50 | 190 | 76 | 190 |

| 75 | 229 | 102 | 132 |

| 100 | 299 | 127 | 283 |

All dimensions are in mm.