3X-Series- Triple eccentric high performance Butterfly Valves – V-TORK CONTROLS

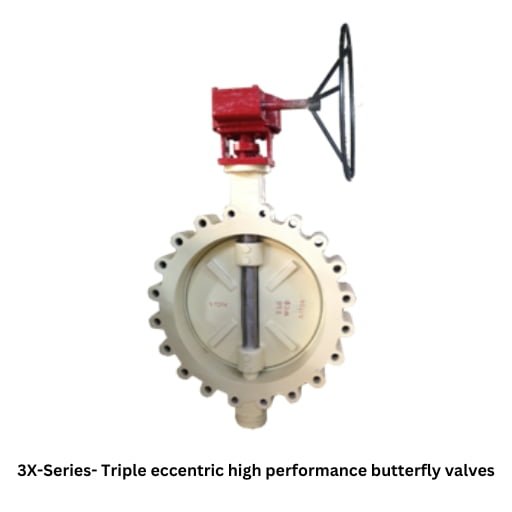

3X SERIES

V-TORK Butterfly Valves are well suited for handling larger flow of liquids and gases alternately of low pressure and for handling of liquids with suspended solids (Slurries).

Specifications

- Size: 2” to 50” (40mm to 1200mm)

- Wafer, Lug, Flanged End

- Class #150.

- Double Tripple Type

- Standard: BS 5155

Fabricated Valves as per customer requirement.

Applications:

Range of Material of Construction Disc: WCB / CF8 / CF8M / DI / CI & any special metallurgy on customer request; Stem: AISI 410 / 304 / 316; Body: CI / WCB / CF8 / CF8M Range of Seat Materials EPDM / Viton / Natural Rubber / Nitrile /PTFE/Metal Seat

Range of Actuators Manual – Lever Operated, Gear Operated, Pneumatic Actuated, Motorized with Complete Automation

Butterfly valve manufacturers

The global butterfly valve market reached a value of US$ 9.39 billion in the past year. Butterfly valve manufacturers produce butterfly valves with a 4.1 % CAGR. A butterfly valve is a quarter-turn valve consisting of two semicircular rotating plates connected to a rod used to stop, regulate or start the flow of liquids through the pipe. The valve gets its name as it has similar movement as butterfly wings with 90-degree motion. Butterfly valves are used in various industries like water treatment plants, food processing, chemical, Power plants, etc.

Characteristics of butterfly valves

- The simple-in-operation butterfly valves have characteristics like simple structure, lightweight design, small volume, low material consumption, small installation size, 90° reciprocating rotation, small driving torque, etc.,

- This fully operated valve is made up of a few operating parts only, so it is suitable for positioning and operation in a limited space.

- When the valve is in the fully open position, the medium flows through the valve body, and there creates a pressure drop for good fluid control characteristics. The low-pressure operation enables good sealing and good regulation performance.

- A streamlined design of the valve makes it energy-saving equipment for industries.

- Butterfly valve manufacturers produce valve rods with good mechanical, corrosion, and scratch resistance properties.

- When the valve is opened or closed it only rotates its position and it does not move up or down and is reliable in structure.

Parts of butterfly valves

Butterfly valves have four major internal components: Body, disk, stem, and seat. Below are the parts of the valves and how they contribute their function to the valve.

Valve body

The valve body of the butterfly valves fits between two pipes or flanges. It protects the internal parts of the valve. The two types include wafer-style and lug-style valves. In wafer style, the valve is connected in the bolt holes of the pipes that run through the body. It prevents backflow in universal flow systems. In lug style, the valves are connected to the pipe through protruding lug holes that run outside the body. The butterfly valve suppliers install butterfly valves at ease.

Disk

The disk is a part that controls the flow of the liquid through the valve. In concentric disk design, the stem of the valves passes through the centerline of the disk in the same direction of media whereas for eccentric disks the stem passes behind the centerline in the opposite flow of liquid. The concentric disk is mostly utilized in low-pressure applications, whereas the eccentric designs are used in severe service applications.

Stem

It is a small part but it has an important role in the operation of butterfly valves. Butterfly valve manufacturers produce two types of stem: Wetted and Non-wetted. The advantage of wetted is that it is protected against any corrosive media in the line, but non-wetted is not protected against any harmful substances.

Seat

Other connections & actuators

There are wafer, lug, and flange connections. Butterfly valve manufacturers design different automatic actuators like electric, pneumatic, hydraulic, worm gear drive. Actuators can be designed with two types: fail open ( valves stay open when there is an actuator failure) and fail-close (valves stay closed when there is an actuator failure) and stay put which comes in general.

Working principle of Butterfly valves

Butterfly valves are used for On/Off isolation or control type applications. It works based on the quick shut-off principle and the main thing is pressure drop. The butterfly valve is mainly utilized to regulate the flow of liquid.

How do they work?

Butterfly valves can be operated both under manual, pneumatic, or electrical. If operated electronically, a signal from the remote control reaches the gearbox which turns the stem, simultaneously the disc moves its position

If pneumatically driven, providing the required air pressure piston attached to the body helps open the valve. Butterfly valve manufacturers suggest that the pneumatic is most suitable for quick operation industrial functions.

If manually operated, the disc rotates and changes its position from perpendicular to parallel the flow of media. The disc drifts away from the seat and aligns with the centerline of the valve. Now, if the valve rod is manually opened in quarter-turn ie.90 degrees, then the medium flows in full force. Then it is closed with a quarter-turn operation. There occurs a slight pressure drop when the valve opens. The quarter-turn valves shall be operated incrementally.

Flow characteristics of butterfly valves

Butterfly valve manufacturers may provide different installed flow characteristics are as follows,

- Linear: Linear flow characteristic is where the flow rate is directly proportional to the amount of disk travel.

- Equal percentage: The phenomenon is that equal increments of valve travel produce equal percentage changes in flow rates.

- Quick opening:

In the quick opening, the flow rate rapidly changes with incremental changes in the valve travel., unlike unidirectional knife gate valves.

Advantages of butterfly valves

- The small size and compact designs make them economical in installation.

- They cover minimal space when compared to other control valves. It has high-quality flow blocking characteristics.

- It is more efficient and quick with automatic actuators in engineered designs.

- Fewer maintenance valves due to fewer parts. Varieties with multiple disc designs.

- The valve seating materials are used easily in different types of environments.

- They are cost-effective, easy to operate, and utilized under a variety of applications with sturdy and rigid designs.

- It has low pressure, high-pressure recovery, and large size availability.

V-Tork, the Butterfly valve manufacturers produce customized valves as per the design requirements of the clients.

Industrial applications of butterfly valves

Most industrial applications go for high tolerant, wear-resistant butterfly valves with special features. Butterfly valve manufacturers recommend butterfly valves for most industrial applications and it tops the choice for industries. In comparison with other control valves, butterfly valves can able to withstand between 150 to 740 psi cold working pressure and temperature up to 300 ℉. It is most apt for steam and water pipelines.

Food processing

Certified food grade valve seats are preferred for food industries. Choose a butterfly valve with a white seat, epoxy coated, nylon, iron, to regulate the liquid flow in food processing pipelines. Sanitary maintenance is more important in food industries.

Refineries

Shipbuilding

Due to its high durability in saltwater, the ABS-approved valves are more effective in ships. The compact design, fire safety, and tight shut-offs make it the best choice in the ship piping system.

Other applications

It has diverse industrial applications in chemical, pharmaceutical, wastewater management, and fuel supply. As large sizes are available from butterfly valve manufacturers, it is suitable for handling large slurries at low pressures.

Valve material

Butterfly valve manufacturers generally use stainless steel, Carbon steel, cast iron, and ductile iron. To hold the pressures for a longer duration and durability purposes, butterfly valve suppliers suggest cast iron as the prime material of choice. The body of the butterfly valves is mostly made up of cast iron, ductile iron, carbon steel, stainless steel, and exotic materials. The disc materials should be carefully chosen so that it does not interact with actual fluid-flowing pipelines. The disc materials include ductile iron, stainless steel, epoxy-coated, and nickel-plated materials. Get premium quality control valves from V-Tork butterfly valve manufacturers.

Types of butterfly valves manufactured by V-Tork

V-Tork controls have been one of the leading butterfly valve manufacturers systems since 2008. Being a good-quality manufacturer, We manufacture butterfly valves under three categories as follows,

C-Series- Concentric type butterfly valves

The concentric butterfly valves with shafts located in the center of the disc have wide applications in handling larger fluids of liquids, gases, and suspended solids at low pressure. The maximum operating pressure is from 16- 25 bar.

2X-Series- Double eccentric high-performance butterfly valves

The high-performance double eccentric butterfly valves are best suited for the liquid and gasses industry. It has varied features like standardized actuation flange, twin disc, polygon stem, and fire safe design. The maximum working pressure is 50 bar and the cold temperature it can withstand is -29℃.

3X-Series- Triple eccentric high-performance butterfly valves

Triple eccentric butterfly valves are designed cone angles along with two eccentric shaft offsets that allow the disc to seal against the seats with zero friction. The main advantage is that the conical sealing design results in extendable valve life.

Things to be considered before purchasing butterfly valves

- Find the right high-quality butterfly valve manufacturers.

- Write down the specifications, focus your search and deliver to your potential valve manufacturers.

- Based on the specification, V-Tork ball butterfly valve manufacturers customize the sizes, functions, and hardware choices for the valve manufacture.

Related products

B-270 – Bi Directional, Lug Type Resilient Seated (U Seal) Knife Gate Valves – V-TORK CONTROLS

B-270

Awwa Knife Gate Valves

Specifications

- Bi Directional, Lug Type

- Size 2” to 40” (50mm to 1000mm)

- Resilient Seated (U Seal)

- Single Piece Construction

- 150 PSI CWP

- Standard: MSS SP-81

Applications:

Liquid/Slurry Application: Abrasive Slurries in Mineral Industries, Pulp Slurry, Chemical Slurry, Molasses, Raw Water Intake, Ash Slurries in Thermal Power Plant, Chemical Slurries in Chemical Process Industries, Sugar Juice in Sugar Industries Bulk Handling (Solids & Powders): Pneumatic Conveying systems, Detergent Powders/Cake, Boiler bed ash, Carbon Black, Coal handling, Lime powder handling applications. Gas Application: Blast Furnace Gas in Steel industries, Pulverized coal fired lines in Thermal Power Plants, Hot gas handling. Powder Applications: Lime powder, Silica/ Magnesium Oxide/ Calcium Oxide/ Al Oxide/ Zyconium Oxide. Range of Material of Construction CI / DI / WCB / CF8 / CF8M / CF3M / CG8M / SMO254 / Duplex 2205 & Special Materials on Request Range of Seat Materials EPDM / Viton / Natural Rubber / Nitrile/ PTFE/ CFT/GFT Range of Actuators Hand Wheel, Lever Operated, Chain Wheel, Bevel Gear, Pneumatic Double Acting/Single Acting Cylinder, Hydraulic Cylinder, Electro-Pneumatic Operation, Motorized Range of Accessories Solenoid Valve, Limit Switch, Proximity Switch, Junction Box, Positioner, Accumulator for Emergency Shut Off, Wear Rings, AFR, Speed Control Valves Range of Addl. Features Deflection cone, V-Orifice, Purge Port, Stem Extension, Fail Safe System, Locking Arrangement, Renewable seats, Non raising Stem arrangement.B-540 – Bi-Directional Lug Type Slurry valve (Short face to face) – V-TORK CONTROLS

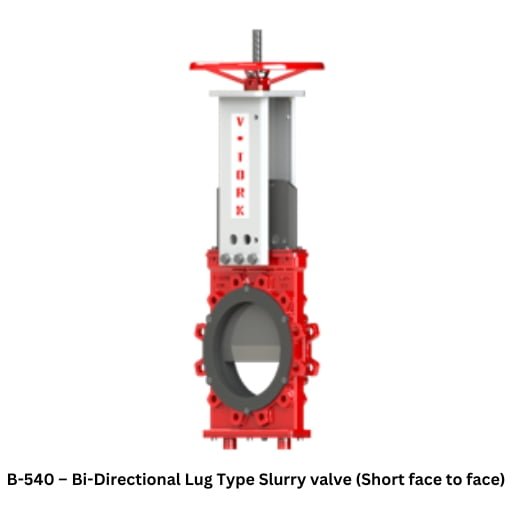

B-540

Slurry Knife Gate Valves

Specifications

- Bi Directional, Lug Type

- Size 2” to 54” (50mm to 1350mm)

- Dual Elastomer Seals with Retainer Rings

- Single Piece Construction

- 150 PSI/300 PSI (18” to 54”) CWP

- Standard: V-TORK Std

Applications:

Liquid/Slurry Application: Abrasive Slurries in Mineral Industries, Pulp Slurry, Chemical Slurry, Molasses, Raw Water Intake, Ash Slurries in Thermal Power Plant, Chemical Slurries in Chemical Process Industries, Sugar Juice in Sugar Industries Bulk Handling (Solids & Powders): Pneumatic Conveying systems, Detergent Powders/Cake, Boiler bed ash, Carbon Black, Coal handling, Lime powder handling applications. Gas Application: Blast Furnace Gas in Steel industries, Pulverized coal fired lines in Thermal Power Plants, Hot gas handling. Powder Applications: Lime powder, Silica/ Magnesium Oxide/ Calcium Oxide/ Al Oxide/ Zyconium Oxide. Range of Material of Construction DI / WCB & Special Materials on Request Range of Seat Materials EPDM /Natural Rubber (Special material on request) Range of Actuators Hand Wheel, Lever Operated, Chain Wheel, Bevel Gear, Pneumatic Double Acting/Single Acting Cylinder, Hydraulic Cylinder, Electro-Pneumatic Operation, Motorized Range of Accessories Solenoid Valve, Limit Switch, Proximity Switch, Junction Box, Positioner, Accumulator for Emergency Shut Off, Wear Rings, AFR, Speed Control Valves, Reed Limit Switch. Range of Addl. Features Purge Port, Drain Port, Stem Extension, Fail Safe System, Locking Arrangement, Non-Raising Stem arrangement…B-540 – Bi-Directional Lug Type Slurry valve (Short face to face) Knife Gate Valves – V-TORK CONTROLS

B-540

Specifications

- Bi Directional, Lug Type

- Size 2” to 54” (50mm to 1350mm)

- Dual Elastomer Seals with Retainer Rings

- Single Piece Construction

- 150 PSI/300 PSI (18” to 54”) CWP

- Standard: V-TORK Std

Applications:

Liquid/Slurry Application: Abrasive Slurries in Mineral Industries, Pulp Slurry, Chemical Slurry, Molasses, Raw Water Intake, Ash Slurries in Thermal Power Plant, Chemical Slurries in Chemical Process Industries, Sugar Juice in Sugar Industries Bulk Handling (Solids & Powders): Pneumatic Conveying systems, Detergent Powders/Cake, Boiler bed ash, Carbon Black, Coal handling, Lime powder handling applications. Gas Application: Blast Furnace Gas in Steel industries, Pulverized coal fired lines in Thermal Power Plants, Hot gas handling. Powder Applications: Lime powder, Silica/ Magnesium Oxide/ Calcium Oxide/ Al Oxide/ Zyconium Oxide. Range of Material of Construction DI / WCB & Special Materials on Request Range of Seat Materials EPDM /Natural Rubber (Special material on request) Range of Actuators Hand Wheel, Lever Operated, Chain Wheel, Bevel Gear, Pneumatic Double Acting/Single Acting Cylinder, Hydraulic Cylinder, Electro-Pneumatic Operation, Motorized Range of Accessories Solenoid Valve, Limit Switch, Proximity Switch, Junction Box, Positioner, Accumulator for Emergency Shut Off, Wear Rings, AFR, Speed Control Valves, Reed Limit Switch. Range of Addl. Features Purge Port, Drain Port, Stem Extension, Fail Safe System, Locking Arrangement, Non-Raising Stem arrangement…B-720 – Bi-Directional flanged Type Slurry valve (Long face to face) Knife Gate Valves – V-TORK CONTROLS

B-720

Specifications

- Bi Directional, Flanged Type

- Size 2” to 64” (50mm to 1600mm)

- Dual Elastomer Seals

- Single Piece Construction

- 2” to 30” 150 PSI CWP/ Above 30” 100 PSI

- Standard: V-TORK Std

Applications:

Liquid/Slurry Application: Abrasive Slurries in Mineral Industries, Pulp Slurry, Chemical Slurry, Molasses, Raw Water Intake, Ash Slurries in Thermal Power Plant, Chemical Slurries in Chemical Process Industries, Sugar Juice in Sugar Industries Bulk Handling (Solids & Powders): Pneumatic Conveying systems, Detergent Powders/Cake, Boiler bed ash, Carbon Black, Coal handling, Lime powder handling applications. Gas Application: Blast Furnace Gas in Steel industries, Pulverized coal fired lines in Thermal Power Plants, Hot gas handling. Powder Applications: Lime powder, Silica/ Magnesium Oxide/ Calcium Oxide/ Al Oxide/ Zyconium Oxide. Range of Material of Construction DI & Special Materials on Request Range of Seat Materials EPDM / Viton / Natural Rubber / Nitrile Range of Actuators Hand Wheel, Lever Operated, Chain Wheel, Bevel Gear, Pneumatic Double Acting/Single Acting Cylinder, Hydraulic Cylinder, Electro-Pneumatic Operation, Motorized Range of Accessories Solenoid Valve, Limit Switch, Proximity Switch, Junction Box, Positioner, Accumulator for Emergency Shut Off, Wear Rings, AFR, Speed Control Valves, Reed Limit Switch. Range of Addl. Features Purge Port, Drain Port, Stem Extension, Fail Safe System, Locking Arrangement, Non raising Stem arrangement.C-Series- Concentric type Butterfly Valves – V-TORK CONTROLS

Butterfly Valves

C SERIES

Specifications

- Size: 1” to 100” (40mm to 2500mm)

- Wafer, Lug, Double Flanged Ends

- Class#150, PN10

- Concentric Type

- Molded Seated / Renewable Seated

- Standard: BS 5155/ API 609/ AWWA C 504

Applications:

V-TORK Butterfly Valves are well suited for handling larger flow of liquids and gases alternately of low pressure and for handling of liquids with suspended solids (Slurries). Size 1” to 50” (25mm to 1250mm) Fabricated Valves as per customer requirement. Range of Material of Construction Disc: WCB / CF8 / CF8M / DI / CI & any special metallurgy on customer request; Stem: AISI 410 / 304 / 316; Body: CI / WCB / CF8 / CF8M Range of Seat Materials EPDM / Viton / Natural Rubber / Nitrile /PTFE/Metal Seat Range of Actuators Manual – Lever Operated, Gear Operated, Pneumatic Actuated, Motorized with Complete AutomationF-Series- Floating Ball Valves – V-TORK CONTROLS

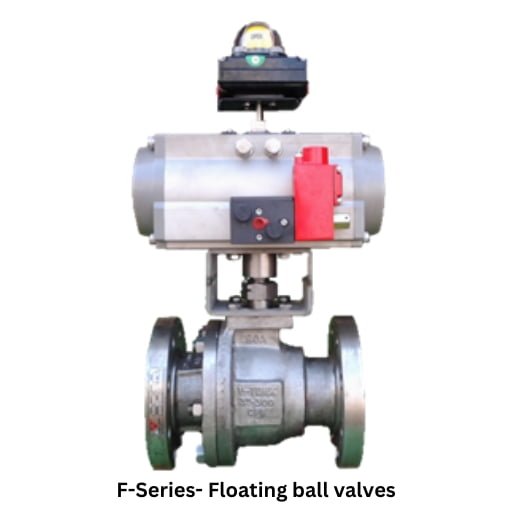

F SERIES

Ball Valves are quarter turn – straight through valves, got its name from the ball that rotates to open & close the valve. Ball valves are widely used in applications where tight shut off is required. V-TORK manufactures Ball valves of 5 different types which are able to transfer gases, liquids & air. The Main advantages are the superior ease of operation, Low purchase & maintenance cost, rugged construction and longer service life.Specifications

- 2 Way

- Size ½” to 8” Class#150, 300 (Soft seated)

- Size ½” to 12” Class#150 (Metal Seated)

- Flanged Ends / Butt Welded

- Standard: BS 5351 / ISO 17292

Applications:

Range of Seat Materials PTFE/ CFT/GFT/PEEK/ Metal seat. Range of Material of Construction WCB / LCB / A105 / CF8 / CF8M / F304 / F316 / CF3 / CF3M / CD4MCU / CN7M & any special metallurgy on customer request. Range of Actuators Manual – Lever Operated, Gear Operated, Pneumatic Actuated, Motorized with Complete AutomationS-Series -Ball Valves Screwed End – V-TORK CONTROLS

S SERIES

Specifications

- 2 Way

- Screwed, But Welded, Socketed

- Size ½” to 2” (15mm to 50mm)

- Class#150, 300, 600, 800

- Metal Seated/ Soft Seated

- Standard: BS 5351 / ISO 17292

U-205- Uni-Directional, Lug type Bonnetted Knife gate valves – V-TORK CONTROLS

U - 205 AWWA

Awwa Knife Gate Valves

V-TORK AWWA/water Knife Gate valve standard describes Bonneted / Bonnetless and one piece/two piece construction which is made of stainless steel /cast iron /ductile iron body with resilient or metal seated knife gate valves. Theses AWWA valves are especially used in water, wastewater, and sludge water systems. V-TORK Valves are specially manufactured by AWWA standard to suit critical water applications.Specifications

- UniDirectional, Lug Type

- Size 2” to 120” (50mm to 3400mm)

- Bonneted / Bonnet Less

- Metal Seated / Soft Seated

- 150 PSI CWP

- Standard: AWWA C520-10