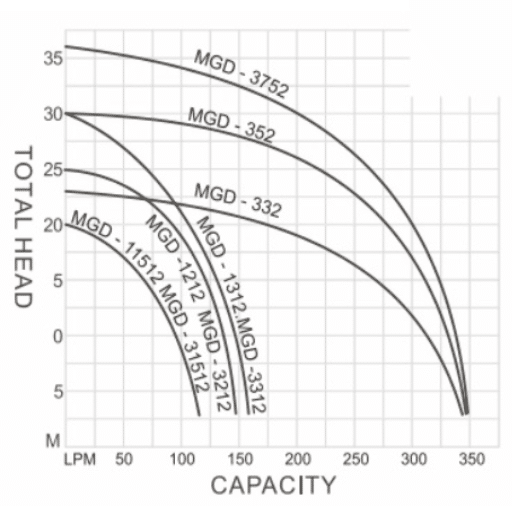

MODY SUBMERSIBLE GRINDER PUMPS

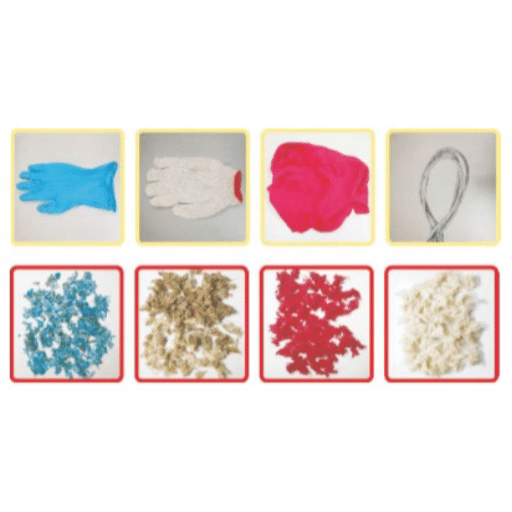

MGD series Grinder Pumps are specially designed and produced to handle waste waters from Industries like Textile, Leather tanneries, Hospitals , Hotel, Residential colonies where fibrous material forms part of the waste water. As these material obstruct discharge likes or often choke the pumps , MGD pumps becomes ideal choice.

The Global Pump GST line handles a wide range of liquids from water and sewage to sludge that can contain solids and other material with flows up to 16,000 gpm (3,634 m°/h) and heads up to 202 feet (62 m). Industry best in fuel efficiency, ease-of-maintenance, and durability.

Related products

MODY ELECTRICAL SUBMERSIBLE DEWATERING PUMP

DESIGN ADVANTAGES

- Stainless Steel Strainer, Shaft, Impeller, Outlet and Hardware for maximum corrosion resistance.

- S$S316 impeller for seawater and corrosive application.

- Tandem Tungsten Carbide/ Silicon Carbide and Tungsten Carbide/Silicon Carbide mechanical seals.

- Mechanical Seals in wholly enclosed pressure compensated oil chamber.

- Field adjustable Nitrile Rubber-lined Diffuser/Wear Plate Optimizes efficiency throughout the life of the pump.

- Equipped with Sacrificial Zinc Anodes for maximum life in a saline Fluid environment.

- Viton Elastomers.

- Thermal Overload Protection

- 2.5" instantaneous coupling for quick fixing. NOTE:

- Pumps complies to IP 68 Dewatering pumps are available up to 1000 TPH

- Complies to Shock Grade “B / NSS II” Also available in Stainless Steel MOC

- Mould (Fungus) Growth Test as per JSS 55555.

MODY SLURRY & SAND PUMPS

MODY LIGHT SLURRY PUMPS

Mody Light Slurry (MLS) series pumps are electric submersible pumps fitted with agitator for handling slurry & sand etc...FEATURES

- Slim design with a top discharge enabling installation in smaller space.

- The top discharge, side flow design assures efficient motor cooling even when it operates with its motor exposed to air.

- Extra Durability of Wear components due to 28% Hi Chrome metallurgy of hydraulic components viz. Impeller, Wear plate , Agitator.

- Low speed pump - 1480 RPM.

- Built-in shaft mounted agitator suspends solids easily and thus these solid particles are smoothly guided through powerful Suction of the pump.

- Semi Open impeller designed for best pump performance

- Dual inside mechanical seal with SiC faces provides longest operational life

APPLICATIONS

- Atconstruction site

- In Sewage treatment plants

- Waste water handling

- AtMines & For handling thick slurries - Clay / bentonite ..

EAVY DUTY SERIES HAVING OPTIONS

- Cooling jacket over motor

- Water jet arrangement

- Motorised side Agetator

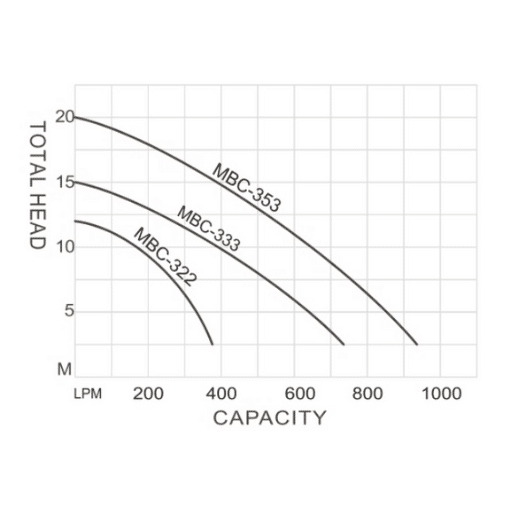

MODY SUBMERSIBLE CUTTER PUMPS

MBC series pumps are fitted with a high-hardness & high-efficiency cutting blade with a cutting disc at the bottom of the impeller for better performance of cutting fabrics , stringy material prior to pumps and preventing blockage.

Motor is protected with Epoxy filled Cable entry ports on one side and with a high-quality dual SIC mechanical seal on Pump side.

The motor is having B class(130°C) insulation & auto-cut function to prevent the motor from overheating.

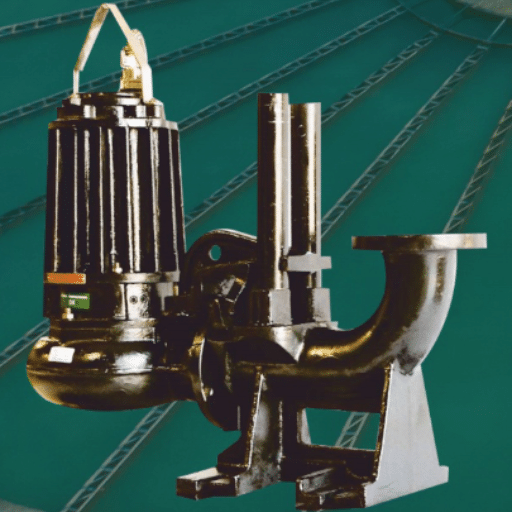

MODY SUBMERSIBLE SEWAGE & WASTE-WATER PUMP

UNIQUE FEATURES

- Robust and Sturdy pump known to reliably deal with sewage water or wastewater,

- Pumps are available from 2 HP to 20 HP, 1480 rpm motor, H Class Insulation. Motors built up with thermal protectors which trip the motors at Class B (130 °C). Ms6150 is supplied with six pole motor.

- Available in Cast Iron construction as a Standard, with options of Wet ends in 2-3% NiCl / SS Volutes and SS Impellers.

- Choice of impellers - Channel / Vortex.

- Pumps are supplied with Double mechanical seal of TC/TC face combination.

- Installation type available. i.Portable with Hose connections / Flanged connection and Pump Base. ii. Wet pit installation along with Duck foot bend & Auto coupling.