Forged Ball Valve

Product Description

| Size | 1/4″ to 2” (8mm to 50mm) |

| Pressure Rating | ASME 150# to 900# |

| Design Standard | BS EN 17292 |

| Pressure / Temp. | ASME B 16.34 |

| Testing Std. | BS 12266-1 |

| Construction | Bolted |

| End Connection | Screwed, Socket Weld, Flanged, Butt-Weld, Nipple Extended |

| Operation | Lever |

| Material | A105N, LF2, F304L, F316L, F317, F321, F347,F5, F9, F11, F22, F91, F51, F53, F55, F60, Inconel, Monel, Alloy 20, Nickel Aluminium Bronze |

Related products

Ball Valves One/Two Piece, Fire Safe-Antistatic design, Full bore Flange end (150#,300#)

Description

One Piece body from DN 15 to DN 40 and Two-piece design from DN 50 to DN 200 valve size. Ideally suitable for use in oil and gas production, refining and chemical applications. Body material and wetted trim components confirms to NACE standard MR 0175. Fire safe and Anti-static design where Hazardous areas with handling of flammable fuels, gases or chemicals are in use.Technical Data :

- Size Range: DN 15 – DN 40 (One piece), DN 50 – DN 200 (Two piece)

- Pressure rating: ASME Class 150 & 300

- Temperature range: Up to 260 deg. C

- Seat: PTFE / Carbon Reinforced PTFE

- End Connections: Flanged ASME B16.5

- With & Without ISO PAD

- MOC : WCB, PTFE, CF8, 304 S/S, 316 S/S, MS, CF8M, SS, Carbon R’PTFE

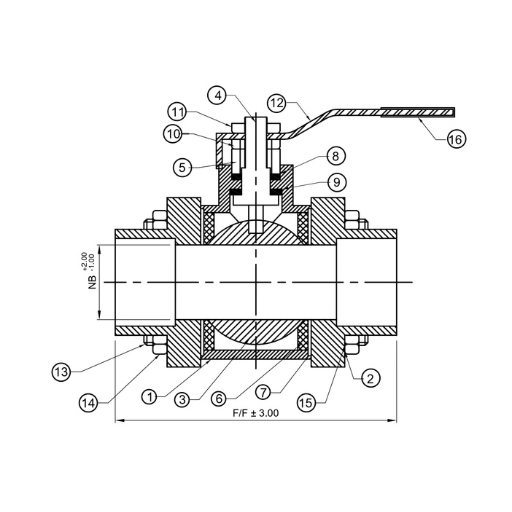

Ball Valves Three Piece, Full Bore (Screw End, Socket Weld) (150#, 300#, 600#, 800#)

Technical Data :

| Design Std. | As per ISO 17292 & BS 5351 |

| End Connection | Screwed End/Socket Weld |

| Testing & Std. | As per API 598 / ISO 5208 |

| Size, 150# | 15 mm to 50 mm (1/2" to 2") |

Material (MOC)

| Sr. No. | Description | Material |

| 1 | Body | WCB / CF8 / CF8M |

| 2 | Adaptor | WCB / CF8 / CF8M |

| 3 | Ball | CF8 / CF8M |

| 4 | Steam | SS304 / SS316 |

| 5 | Gland | SS304 / SS316 |

| 6 | Seat Ring | PTFE / GFT /CFT |

| 7 | Body Seal | PTFE / GFT /CFT |

| 8 | Gland Packing | PTFE / GFT /CFT |

| 9 | Steam Seal | PTFE / GFT /CFT |

| 10 | Gland Nut | MS/SS304 |

| 11 | Lever Nut | MS/SS304 |

| 12 | Lever | MS/SS |

| 13 | Stud | MS/SS304 |

| 14 | Stud Nut | MS/SS304 |

| 15 | Stud Washer | MS/SS304 |

| 16 | Lever Sleeve | PVC |

Dimensions 150#

| Size | NB | F/F | Thread Type |

| 15 | 12.5 | 62.5 | BSP/NPT/SW |

| 20 | 19.0 | 74.0 | BSP/NPT/SW |

| 25 | 25.0 | 87.0 | BSP/NPT/SW |

| 40 | 38.0 | 109.0 | BSP/NPT/SW |

| 50 | 50.0 | 110.0 | BSP/NPT/SW |

All Dimensions are in mm

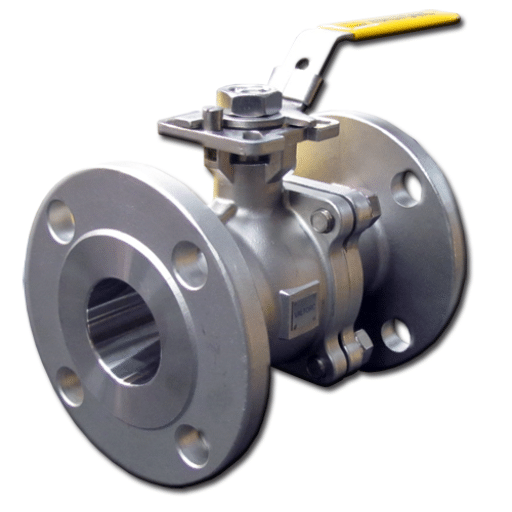

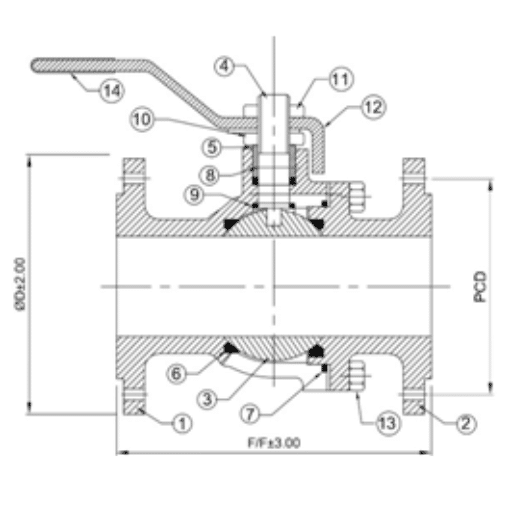

Ball Valves Two Piece, Full Bore, Flange end (150#, 300#)

Technical Data :

| Design Std. | As per ISO 17292 & BS 5351 |

| End Connection | Flanged End |

| Testing Std. | As per API 598 or ISO 5208 |

| Size 150# & 300# | 15 mm to 300 mm (1/2" to 12") |

BILL OF MATERIALS

| Sr. No. | Description | Material |

| 1 | Body | CI / WCB / CF8 / CF8M |

| 2 | Adaptor | CI / WCB / CF8 / CF8M |

| 3 | Ball | CF8 / CF8M |

| 4 | Stem | SS304 / SS316 |

| 5 | Gland | SS304 / SS316 |

| 6 | Seat Ring | PTFE / GFT / CFT |

| 7 | Body Seal | PTFE / GFT / CFT |

| 8 | Gland Packing | PTFE / GFT / CFT |

| 9 | Stem Seal | PTFE / GFT / CFT |

| 10 | Gland Nut | MS / SS304 |

| 11 | Lever Nut | MS / SS304 |

| 12 | Lever | MS / SS |

| 13 | Stud | MS / SS304 |

| 14 | Stud Nut | MS/SS304 |

| 15 | Stud Washer | MS/SS304 |

| 16 | Lever Sleeve | PVC |

DIMENSIONS 150#

| Size | Dia D | PCD | F/F |

| 15 | 90 | 60.5 | 108 |

| 20 | 100 | 70 | 117 |

| 25 | 110 | 79.5 | 127 |

| 40 | 125 | 98.5 | 165 |

| 50 | 150 | 120.5 | 178 |

| 65 | 180 | 139.5 | 191 |

| 80 | 190 | 152.5 | 203 |

| 100 | 230 | 190.5 | 229 |

| 150 | 280 | 241.5 | 267 |

| 200 | 345 | 298.5 | 292 |

| 250 | 405 | 362 | 330 |

| 300 | 485 | 432 | 356 |

DIMENSIONS 300#

| Size | Dia D | PCD | F/F |

| 15 | 95 | 66.5 | 140 |

| 20 | 115 | 82.5 | 152 |

| 25 | 125 | 89 | 165 |

| 40 | 155 | 114.5 | 190 |

| 50 | 165 | 127 | 216 |

| 65 | 190 | 149 | 241 |

| 80 | 210 | 168.5 | 283 |

| 100 | 255 | 200 | 305 |

| 150 | 320 | 270 | 403 |

| 200 | 380 | 330 | 419 |

| 250 | 445 | 387.5 | 457 |

| 300 | 520 | 451 | 502 |

All dimensions are in mm.

Belimo Ball Valves

Applications

The ball valve offers high close-off or change-over capabilities without leakage - that's efficiency.Achieve Control and Reliability

The R2, R3 and R6 series ball valves are available with non-spring return, spring return or electronic fail-safe actuators offering high close-off capabilities. The industrial ball valve series is a great solution for low and medium pressure steam applications up to 1000 kPa closed off pressure and applications that operate with a media temperature to 120º C.

High Performance for Aggressive Applications

Belimo industrial ball valves feature 2-way and 3-way configurations operated by rotary actuators. The actuators are controlled by a standard voltage for on/off, modulating, or floating point control which moves the valve to the position dictated by the control system. The series are Leakage rate A, air bubble tight preventing energy loss, which reduces operating costs.

Specification

Pattern: 2-way, 3-way kvs range (kvs): 1.1...3.0 kvs, 3.1...6.5 kvs, 6.6...14 kvs, 15...40 kvs, 41...170 kvs, 171...1000 kvs Valve size (mm): 15 mm, 20 mm, 25 mm, 32 mm, 40 mm, 50 mm, 65 mm, 80 mm, 100 mm, 125 mm, 150 mm Pipe connection: Flange, Internal threadCast Ball Valve

Product Description

| Size | 5/8" to 4” (15mm to 100mm) |

| Pressure Rating | ASME 150# |

| Design Standard | BS EN ISO 17292 |

| Test (Inspection) Standard | ISO 5208 / API 598 |

| Closer Member | SOLID / HOLLOW BALL |

| Construction | 2 PIECE / 3 PIECE SOFT SEATED |

| End Connection | Flanged as per 150# |

| Operation | Lever |

| Material | WCB, CF8, CF8M |

Cast Gate Valve

Product Description

| Size | 1-1/2" to 12” (40mm to 300mm) |

| Pressure Rating | ASME 150# |

| Design Standard | API 600 |

| Pressure / Temp. | ASME B 16.34 |

| Testing Std. | API 598 |

| Construction | Bolted Bonnet |

| End Connection | Flanged |

| Operation | Hand Wheel |

| Material | WCB, LCB, CF8, CF8M, CF3, CF3M, CG8M, CF8C, C5, C12, WC6, WC9, C12A, 4A, 5A, 6A, Inconel, Monel, CN7M, Nickel Aluminium Bronze |

Forged Check Valve

Product Description

| Size | 1/4" to 2” (8mm to 50mm) |

| Pressure Rating | ASME 150# to 2500# |

| Design Standard | API 602 |

| Pressure / Temp. | ASME B 16.34 |

| Testing Std. | API 598 |

| Construction | Bolted Cover / Pressure Seal Cover |

| End Connection | Screwed, Socket Weld, Flanged, Butt-Weld, Nipple Extended |

| Operation | Self |

| Material | A105N, LF2, F304L, F316L, F317, F321, F347,F5, F9, F11, F22, F91, F51, F53, F55, F60, Inconel, Monel, Alloy 20, Nickel Aluminium Bronze |

S-Series -Ball Valves Screwed End – V-TORK CONTROLS

Ball Valves are quarter turn — straight through valves, got its name from the ball that rotates to open & close the valve. Ball valves are widely used in applications where tight shut off is required. V-TORK manufactures Ball valves of 5 different types which are able to transfer gases, Liquids & air. The Main advantages are the superior ease of operation, Low purchase & maintenance cost, rugged construction and longer service life.

S SERIES

Specifications

- 2 Way

- Screwed, But Welded, Socketed

- Size ½” to 2” (15mm to 50mm)

- Class#150, 300, 600, 800

- Metal Seated/ Soft Seated

- Standard: BS 5351 / ISO 17292